- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SINOTECH

-

Year:

-

2022

-

Voltage:

-

According to customer request

-

Dimension(L*W*H):

-

6.8x3.5x5.0m

-

Hollow part volume:

-

250L

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

30.2 kW

-

Extruder Motor Power(kW):

-

90 kW

-

Mold Platen Size(Width)(mm):

-

1300 mm

-

Mold Platen Size(Height)(mm):

-

1400 mm

-

Air Pressure(MPa):

-

1 MPa

-

Air Comsumption(m³/min):

-

1.8 m³/min

-

Die Head Heating Power(kW):

-

31.2 kW

-

Accumulator Capacity(L):

-

20 L

-

Power (kW):

-

80

-

Weight (T):

-

24

-

Keywords:

-

Extrusion blow molding machine

-

Production capacity:

-

20-25pcs/hr

-

Plasticizing capacity:

-

250kg/H

-

Screw diameter:

-

120mm

-

Clamping system:

-

Tie-bar less design

-

Platen dimension:

-

1300x11400mm

-

Platen opening distance:

-

600-1600

-

Microcomputer Control System:

-

MITSUBISHI

-

Motor:

-

Siemens Brand

-

Contactor:

-

Schneider Brand

Quick Details

-

Clamping Force (kN):

-

1200

-

Output (kg/h):

-

250 kg/h

-

Warranty of core components:

-

1 years

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SINOTECH

-

Year:

-

2022

-

Voltage:

-

According to customer request

-

Dimension(L*W*H):

-

6.8x3.5x5.0m

-

Hollow part volume:

-

250L

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

30.2 kW

-

Extruder Motor Power(kW):

-

90 kW

-

Mold Platen Size(Width)(mm):

-

1300 mm

-

Mold Platen Size(Height)(mm):

-

1400 mm

-

Air Pressure(MPa):

-

1 MPa

-

Air Comsumption(m³/min):

-

1.8 m³/min

-

Die Head Heating Power(kW):

-

31.2 kW

-

Accumulator Capacity(L):

-

20 L

-

Power (kW):

-

80

-

Weight (T):

-

24

-

Keywords:

-

Extrusion blow molding machine

-

Production capacity:

-

20-25pcs/hr

-

Plasticizing capacity:

-

250kg/H

-

Screw diameter:

-

120mm

-

Clamping system:

-

Tie-bar less design

-

Platen dimension:

-

1300x11400mm

-

Platen opening distance:

-

600-1600

-

Microcomputer Control System:

-

MITSUBISHI

-

Motor:

-

Siemens Brand

-

Contactor:

-

Schneider Brand

Product Description

STD-250A

Accumulator Extrusion Blow Molding Machine

Machine Features

1. Special design for Max 250L, HDPE/PE/PP stacking barrels, spine board, water life board

2. Die head design with easily to change the material and color.

3. Latest mold changing system, much faster and easier.

4. Optimized hydraulic system, proportional pressure control

5. Adopts two pull-rod type closing-mold device by rack and pinion system.The large setting platen is suitable for various sizes of molds

6. Simple structure in linear type ,easy in installation and maintation.

7. Servo system

8. With robot arm take out the finished product

9. One to three multi-layers choosen

3. Latest mold changing system, much faster and easier.

4. Optimized hydraulic system, proportional pressure control

5. Adopts two pull-rod type closing-mold device by rack and pinion system.The large setting platen is suitable for various sizes of molds

6. Simple structure in linear type ,easy in installation and maintation.

7. Servo system

8. With robot arm take out the finished product

9. One to three multi-layers choosen

10. Hydraulic and electric hybrid power design, it makes the machine running more speed and more energy saving

11. Full Servo system control.

12. Simple structure in linear type, easy in installation and maintenance.

13. With robot arm take out the finished product.

14. Single die-head Single station.

Specification

|

Technical Specification

|

|

STD-250A Accimulator Die-head

Extrusion Blow Molding Machine

|

||

|

Specifications

|

|

STD-250 (Single station)

|

||

|

Material

|

|

HDPE/PE/PP/ABS...

|

||

|

Max container capacity

|

L

|

250

|

||

|

Output (dry Cycle)

|

pc/hr

|

300

|

||

|

Machine Dimension(LxWxH)

|

M

|

7.8x2.9x5.4

|

||

|

Total weight

|

T

|

35

|

||

|

Clamping system

|

|

|

||

|

Clamping force

|

KN

|

770

|

||

|

Platen opening stroke

|

mm

|

800-1800

|

||

|

Max mould size(WxH)

|

mm

|

1200x1720

|

||

|

Power

|

|

|

||

|

Air pressure

|

Mpa

|

1

|

||

|

Air consumption

|

m3/min

|

2

|

||

|

Extruder system

|

|

|

||

|

Screw diameter

|

mm

|

120

|

||

|

Screw L/D ratio

|

L/D

|

32

|

||

|

Melting capacity

|

kg/hr

|

320-380

|

||

|

Number of heating zone

|

zone

|

5

|

||

|

Extruded heating power

|

KW

|

23.6

|

||

|

Extruder driving power

|

KW

|

132

|

||

|

Accumulator head

|

|

|

||

|

Number of hearting zone

|

zone

|

6

|

||

|

Power of die heating

|

KW

|

15

|

||

|

Accumulator capacity

|

L

|

22

|

||

Details Images

Mouth-die

20L large Accumulator die-head insurance the extrusion capacity is enough for large and weight products

Blow pin stroke control including switch

Blow air method control

Adjust of blow pin position

Automatic robot take out unit is the necessary parts for blow molding machine to ensure the workers operation safe.

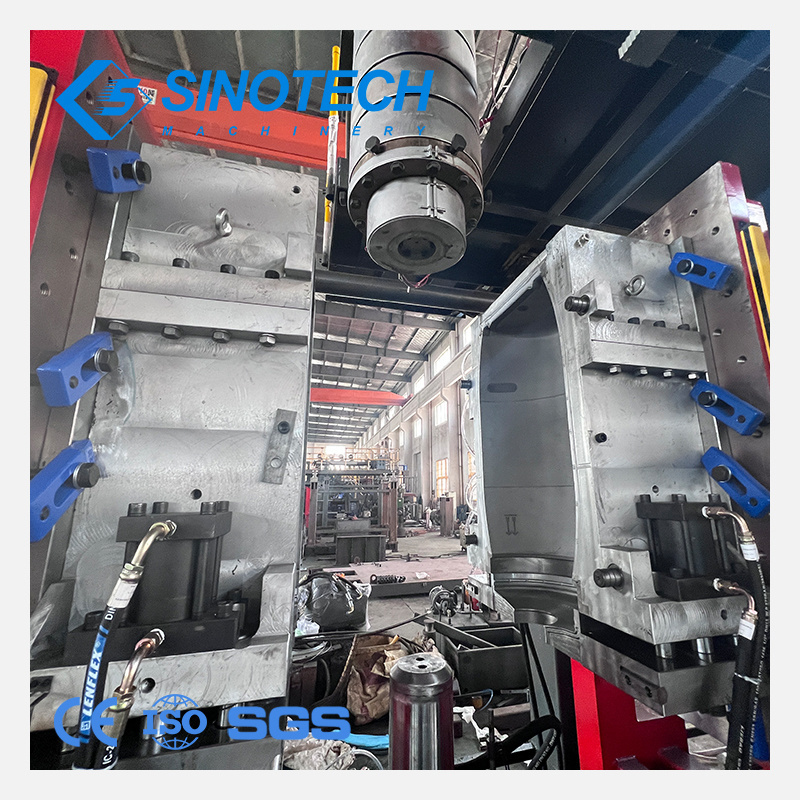

Clamping Unit

With Sinotech patented

two-bar timing clamping structure in high speed and high force to achieve quality products

For high precise location for longer service life.

For high precise location for longer service life.

Seller Recommendation

Hot Searches