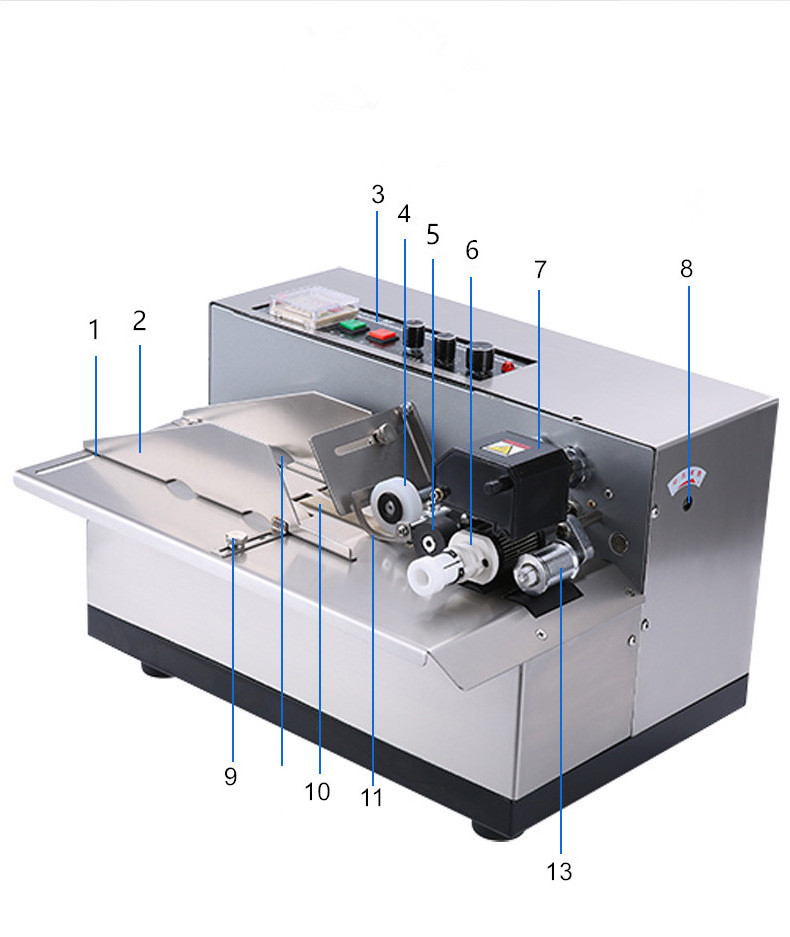

1: guide plate adjust screw

2: guide plate

3: control penal

4: Reverse wheel

5: convey wheel

6: code wheel

7: ink roller

8: Reverse wheel adjust botton

9: table screw

10: feeding wheel

11: convey belt

12: pressure plate

13: exit pressing wheel

- Product Details

- {{item.text}}

Quick Details

-

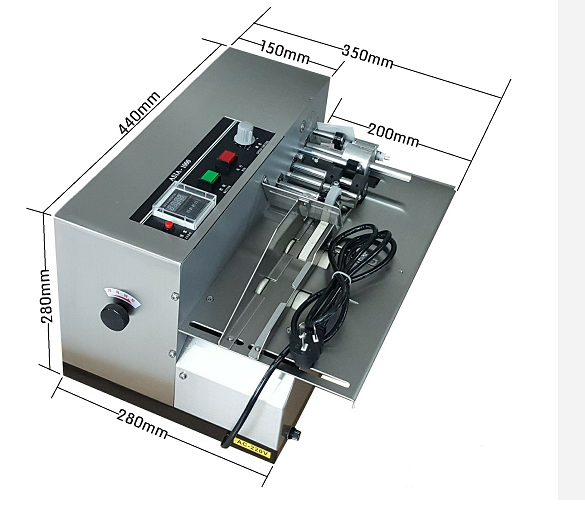

Dimension(L*W*H):

-

44*34.5*26CM

-

Weight:

-

28 KG

-

printing content:

-

expiry/production date

-

automatic date code printer link:

-

solid ink roll

-

automatic date code printer color:

-

black/red

-

bag date printer grain:

-

number/alphabet

-

automatic date code printer ink size:

-

35 * 15 mm

-

automatic date code printer speed:

-

300times/min

-

date coding machine line:

-

R: 5 lines, T: 8 lines

Quick Details

-

Automatic Grade:

-

Automatic

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/110V

-

Dimension(L*W*H):

-

44*34.5*26CM

-

Weight:

-

28 KG

-

printing content:

-

expiry/production date

-

automatic date code printer link:

-

solid ink roll

-

automatic date code printer color:

-

black/red

-

bag date printer grain:

-

number/alphabet

-

automatic date code printer ink size:

-

35 * 15 mm

-

automatic date code printer speed:

-

300times/min

-

date coding machine line:

-

R: 5 lines, T: 8 lines

Products Description

automatic solid ink coding machine

structure

Hot stamping date coding machine MY380 coding machine with ink printing

MY-380 Automatic dry-ink coding machine suits for printing labels on the surface of paper, non-ferrous plastic film and aluminum foil. It applies advanced dry-ink roller for printing and can make the words be printed clearly and uneasy to decay and change.The numbers sizes of this coding machine are available with 2mm, 2.5mm, and 3mm. You can choose the size you want.

Features

The general coding machine at most print dozens of sheets one minute , but MY-380F ink wheel coding machine speed up to 300pcs/minute and print position with infrared control, the distance error is very small, Each label can be printed in the same location.Note: be sure to print code before the product packaged

Change ink wheel and print wheel step:

1. Turn the bakelite baffle counterclockwise.

2. Take out the ink wheel fixed sleeve, remove the old, change the new and then put the fixed sleeve back, clockwise cover the baffle.

1. Turn the bakelite baffle counterclockwise.

2. Take out the ink wheel fixed sleeve, remove the old, change the new and then put the fixed sleeve back, clockwise cover the baffle.

|

model

|

standard model

|

width model

|

|

voltage

|

110/220V

|

110/220V

|

|

power

|

180W

|

180W

|

|

max coding speed

|

300/min

|

300/min

|

|

printing line

|

T:8line

R: 5line

|

T:8line

R: 5line

|

|

front size

|

2mm, 2.5mm 3mm

|

12mm, 2.5mm 3.5mm

|

|

suitable size

|

L: 50-300mm W: 30-190mm

|

L: 50-500mm W: 30-190mm

|

|

machine size

|

440*345*300mm

|

440*465*300mm

|

|

machine body

|

steel

|

steel

|

|

weight

|

23kg

|

24kg

|

Details Images

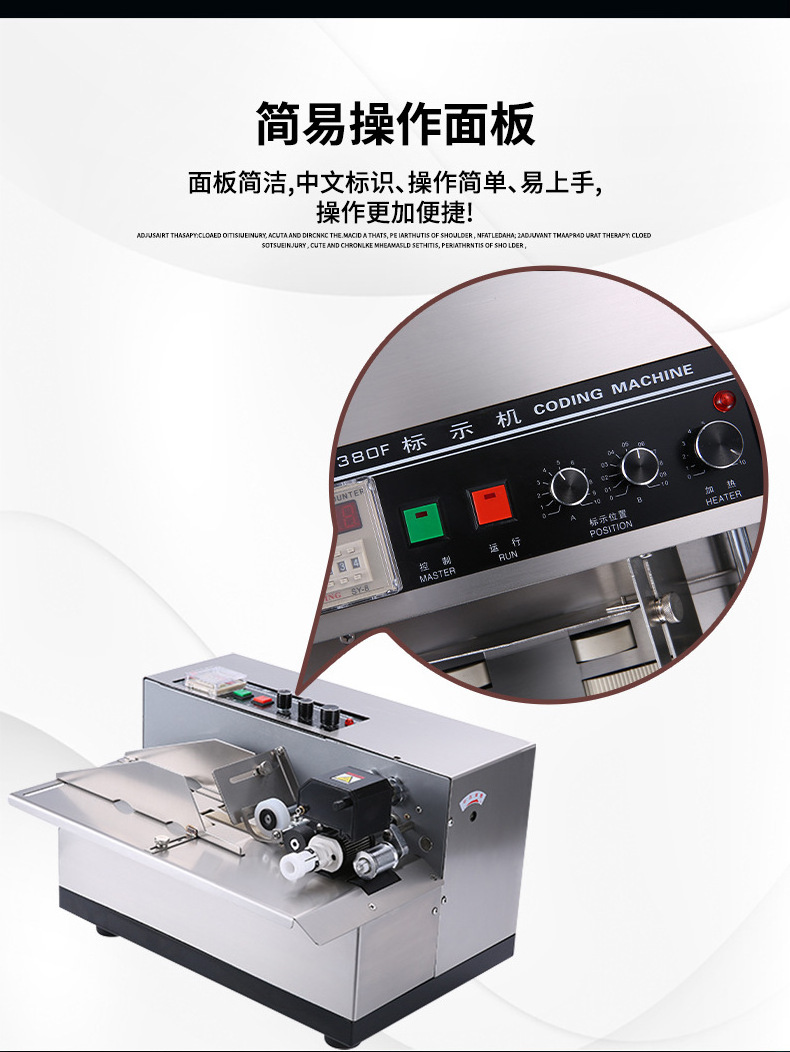

Simple interface .Chinese English translation ,simple operation and easy to use

thickness adjustment

can set printing position and speed

convey belt

Continuous printing and transportation,intelligent and convenient

printing wheel with solid ink roller printing

Intermittent heating ,stable operation ,clear coding and ling service life

standard model

width model

How to change the ink roller

1.Counter-clockwise open the bakelite baffle

2.Remove the fixing sleeve of the ink wheel,take out the old ink roller ,install a new ink roller ;then put the fixed sleeve back ;cover the baffle clockwise

3.When using a solid ink roller turn on the heating switch to preheat.After 5 -8 minutes of scale value "10".Then adjust the temperature switch to the engrave value of 7-8

Product shows

Application

company profile

Hot Searches