- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yurui

-

Capacity:

-

10000 sqm/day

-

Gypsum ceiling board LengthXwidth:

-

595*595mm,600*600mm,603*603mm,1200*600mm

-

Gypsum ceiling board Thickness:

-

7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm

-

Power:

-

220/380V±10%

-

Frequency:

-

(50±1)Hz

-

Usage:

-

Produce

-

Advantages:

-

High Efficent

-

Certification:

-

CE

-

Automation:

-

Automatic Line

Quick Details

-

Weight (KG):

-

22000

-

Core Components:

-

Machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yurui

-

Capacity:

-

10000 sqm/day

-

Gypsum ceiling board LengthXwidth:

-

595*595mm,600*600mm,603*603mm,1200*600mm

-

Gypsum ceiling board Thickness:

-

7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm

-

Power:

-

220/380V±10%

-

Frequency:

-

(50±1)Hz

-

Usage:

-

Produce

-

Advantages:

-

High Efficent

-

Certification:

-

CE

-

Automation:

-

Automatic Line

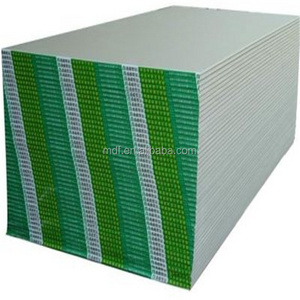

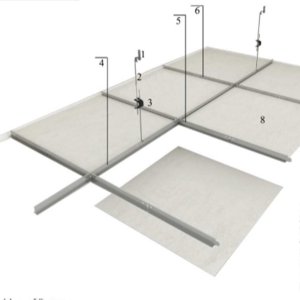

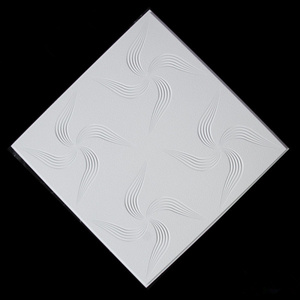

PVC ceiling tiles production line

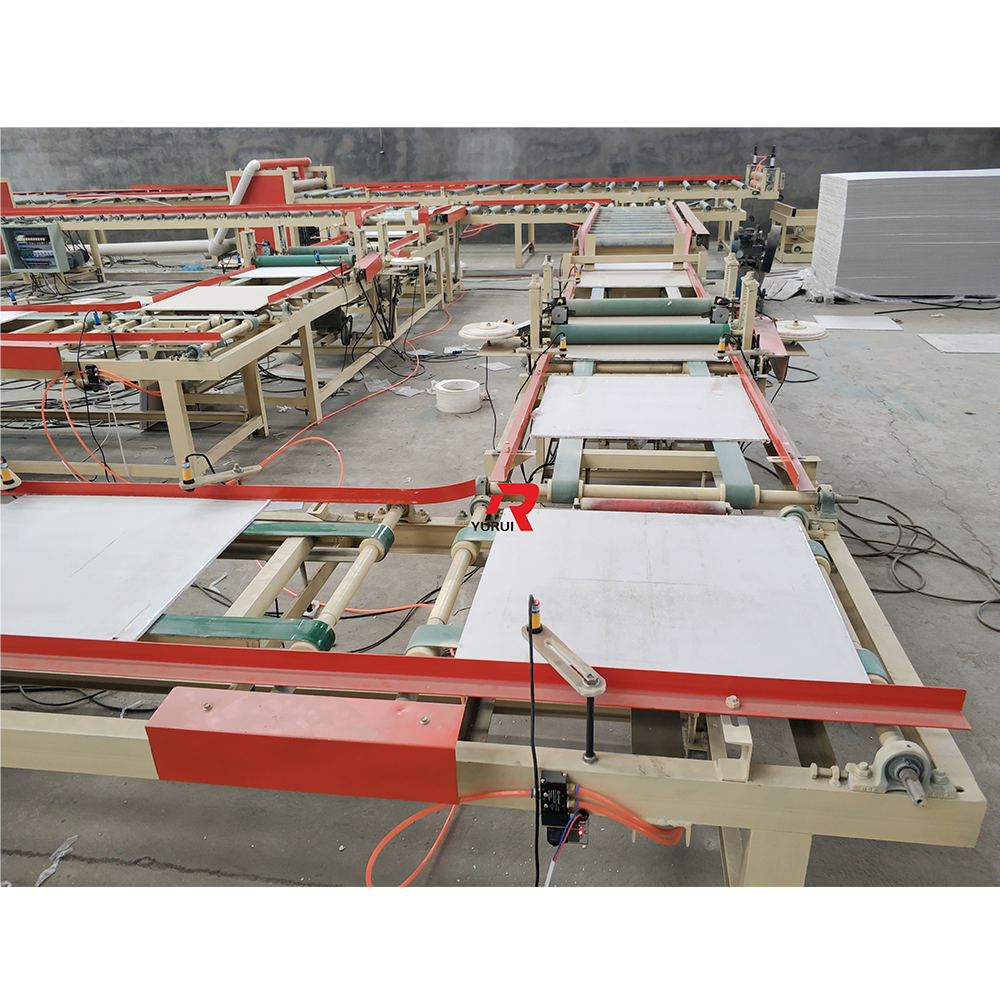

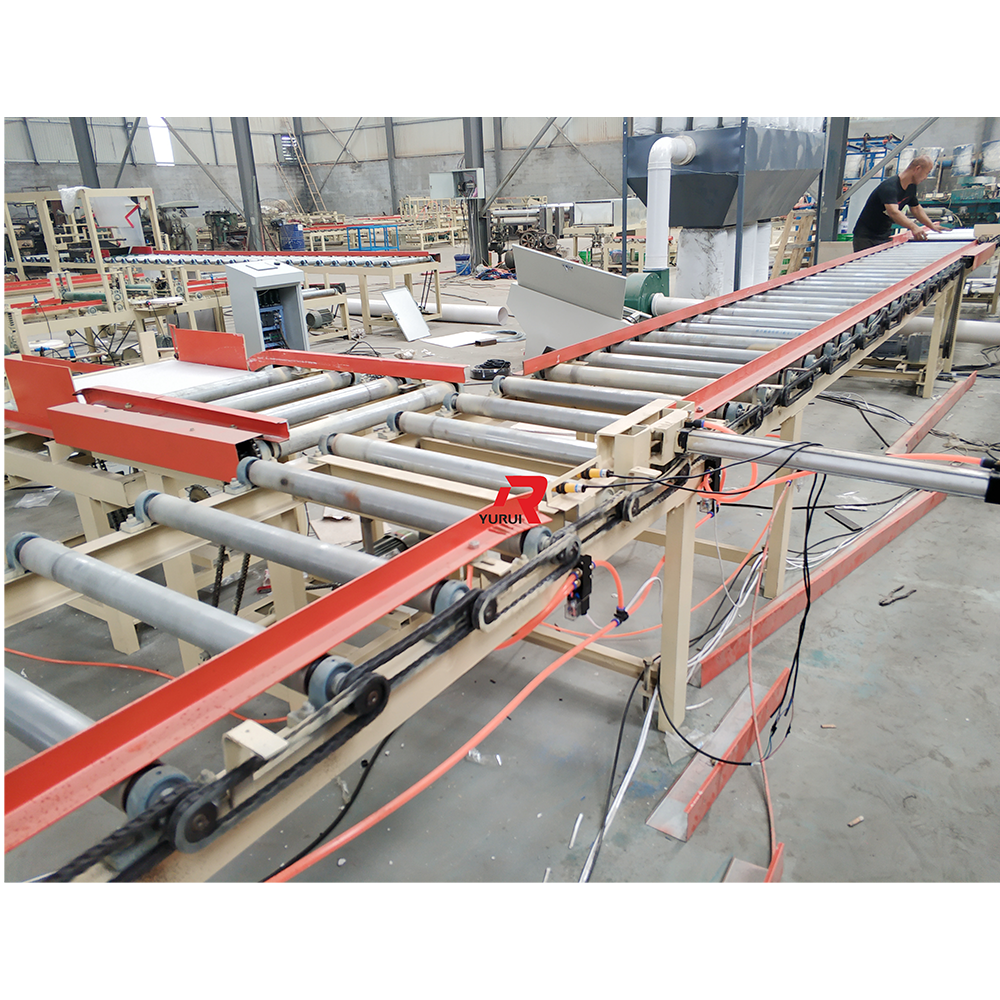

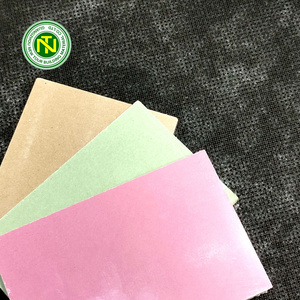

Our PVC ceiling tiles production line is a new kind of products in the domestic market and is dedicated device for producing PCV ceiling tiles board. The production line is controlled by the computer and conveyed by chains and wheels, automatically accomplishing coating, heating, laminating, cold pressing and hot pressing. It is of advanced technology, compact and reasonable structure, simple and reliable operation. nice and good appearance. At present, PVC ceiling tiles board is used in the home-decorating , owing the advantage of moisture-proof, light, sound-proof, various specification, beautiful decoration, convenient construction and getting approval by market and customers step by step.

|

Capacity

|

10000 sqm/day

|

|

Power

|

220/380V±10%

|

|

Gypsum ceiling board LengthXwidth

|

595*595mm,600*600mm,603*603mm,1200*600mm

|

|

Gypsum ceiling board Thickness

|

7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm

|

Main Equipment Introduction

Fully automatic double-sided sticker machine

This machine can complete double-sided film at one time, which is more efficient than the previous single-sided film laminator (laminator), greatly saving manpower and material resources. And it can better achieve the firmness of the film and greatly save the use of glue. This machine comes with a special heating equipment, which can ensure the normal use in winter.

Automatic cutting saw device

Adopt two-way cutting technology to complete gypsum board cutting at one time. The spacing between Saw Blades is adjustable, which can meet the production and processing needs of ceilings of various sizes. It is easy to change the size without large-scale disassembly. The trimming is neat and smooth, and the efficiency is high.

Automatic Side Packing

Use photoelectric switch, automatic sensing device, after receiving the signal, automatically deliver the plate, and finish edge sealing. This machine has fast working speed and high efficiency, can save a lot of manpower and material resources, and is currently an advanced ceiling edge sealing equipment.

Automatic Packer

The machine has compact structure, stable performance and simple operation. The packaging of this unit is the most advanced equipment for ceiling packaging at present, with fast speed, high output and a large amount of manpower and material resources.

Automatic

Adjustment

Temperature

Shrink Machine

This machine performs heat shrinkage on the gypsum board after sealing and packaging, uses infrared heating to shrink film, and uses wind circulation system in the contraction heating chamber to make the indoor temperature more uniform and make the contraction of each part of the object more reasonable. It has the effects of strict sealing, moisture-proof, pollution-proof and beautiful appearance.

Advantages

After-sale service

Our company established a perfect after-sale system, especially at the beginning of the line installation we began to train the users how to use and maintain the equipment. If the user has the problems we will help users solve the problem at the first time.

Technology

Gypsum pvc ceiling machine we designed has national invention patent, and it’s high degree of automation. Gypsum pvc ceiling tiles produced no matter from quality and aesthetic measure, both can get leading level at the same industry. Production line from the mould supplying to the packaging, only need few manual operation, greatly improving the efficiency, reduce the production cost.

Production process

Our workers from the engineers to general production personnel all have rich experience in machinery design and manufacturing.Our equipment not only save materials but also stable security.

Perfect design system

We can design and improve the scheme according to customer's site and other situation,and make the machinery completely conformity with user’s needs.

Hot sale product

Why choose us

Our company has more than 10 years experience on the machinery project.Yurui is responsible for the mgo board production line; eps,concrete wall panel production line; mask machine production line;etc.

Our customers are located in more than 20 countries and regions around the world. We have a professional team,high-quality products and 24-hour after-sales warranty service. We will focus on our field and provide better services for our customers.

Our Factory

Our philosophy

1. We are not selling the board or selling the machine.

2. What we focus is customers demands, keep innovation, keep updating, meet & transcend customers' requirements.

3.What we provide is not ONLY the machine, but the whole system.

Value-Added Service

Spare parts for free

Spare parts list-paid

Installation tool list

Operating manual

It's really good for the customers to say yes.

Since the establishment of our company, we have cooperated with more than 100 overseas customers. We have always served our customers with a professional attitude and won favorable comments from many customers.

We believe that professionalism will enable us to better serve customers.

We look forward to establishing good cooperative relations with more customers.

Packing

Contact

FAQ

1. Q: Are factory tours available?

A: Yes, factory tours are available. We look forward to walking interested individuals through our manufacturing facility and introducing you to our unique product.

2. Q: Can load different size in one container?

A: Yes, loading quantity should be calculate.

3. Q: Can you accept OEM & ODM?

A: Yes, we can.

4. Q: Are you a factory?

A: Yes, we are.

A: Yes, factory tours are available. We look forward to walking interested individuals through our manufacturing facility and introducing you to our unique product.

2. Q: Can load different size in one container?

A: Yes, loading quantity should be calculate.

3. Q: Can you accept OEM & ODM?

A: Yes, we can.

4. Q: Are you a factory?

A: Yes, we are.

Hot Searches