- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3600*2500*2700

-

Weight (T):

-

1 T

-

Power (kW):

-

900

-

After-sales Service Provided:

-

Overseas service center available

-

Application:

-

Melting Metal

-

Name:

-

Aluminum Induction Melting Furnace

-

Capacity:

-

10kg~50ton

-

Feature:

-

Environmentally Friendly

-

Use:

-

Matel Melting

-

Max temperature:

-

500C - 2300C (custom Made)

-

Heating Rate:

-

Min Adjustable)

-

Weight:

-

5000.0 KG

-

Power(W):

-

180-22000KW

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SEMC

-

Voltage:

-

750-3400V

-

Dimension(L*W*H):

-

3600*2500*2700

-

Weight (T):

-

1 T

-

Power (kW):

-

900

-

After-sales Service Provided:

-

Overseas service center available

-

Application:

-

Melting Metal

-

Name:

-

Aluminum Induction Melting Furnace

-

Capacity:

-

10kg~50ton

-

Feature:

-

Environmentally Friendly

-

Use:

-

Matel Melting

-

Max temperature:

-

500C - 2300C (custom Made)

-

Heating Rate:

-

Min Adjustable)

-

Weight:

-

5000.0 KG

-

Power(W):

-

180-22000KW

Product Description

Specification

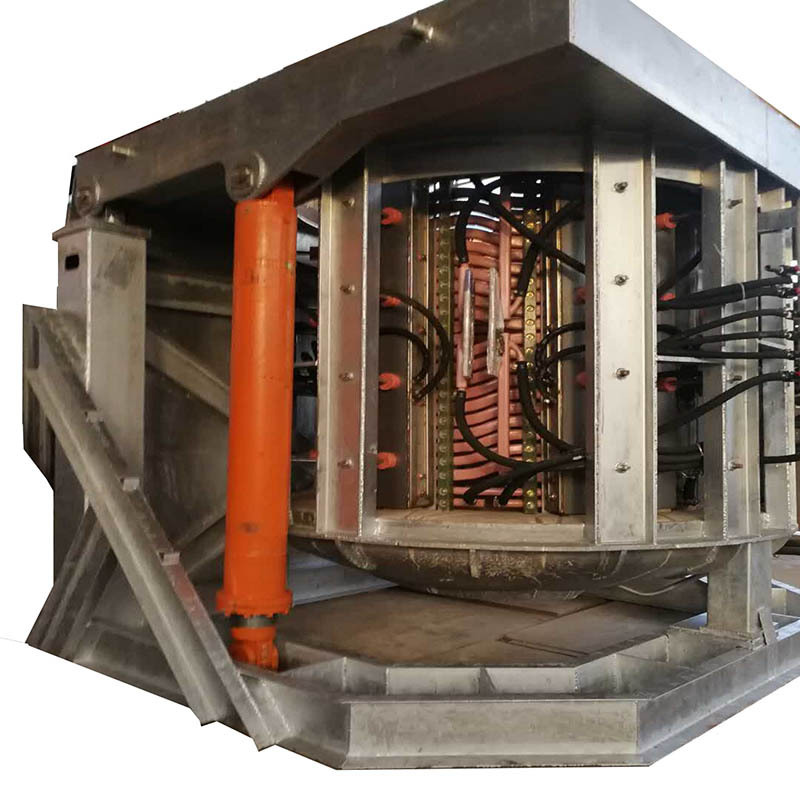

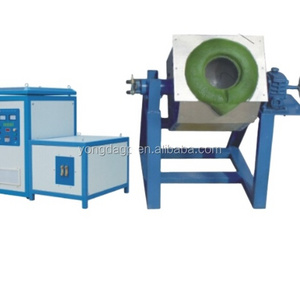

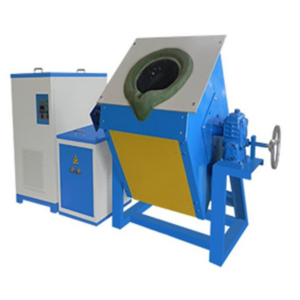

Products Show

Workshop Photo

Hot Searches