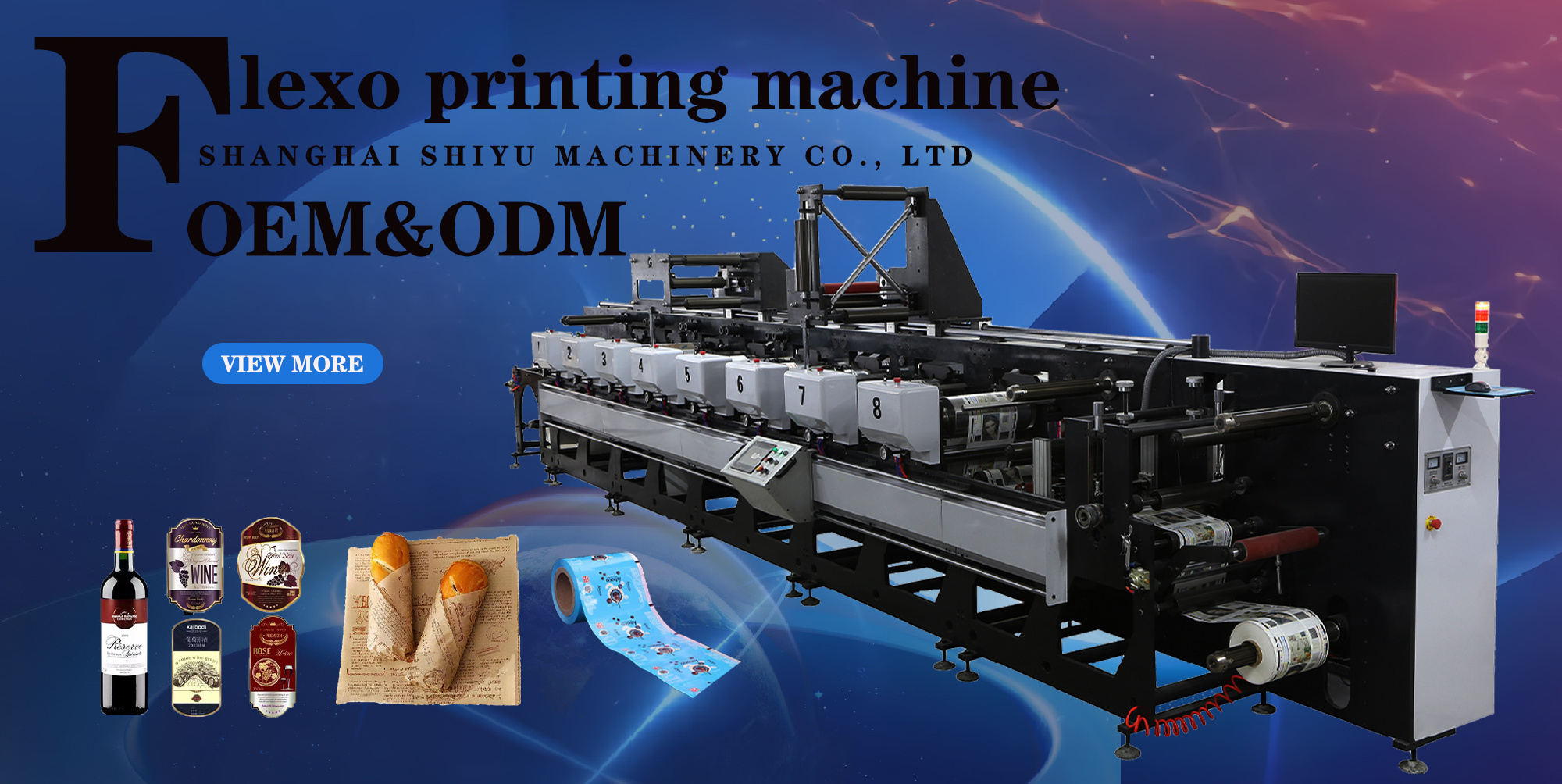

- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

5.2*1.85*3.1m

-

Weight:

-

5200 KG

-

Max Unwinding Diameter:

-

1400mm

-

Max Rewinding Diameter:

-

1400mm

-

Printing speed:

-

5-120m/min

-

Printing Circumference:

-

254--508mm

-

Max Web Width:

-

950mm

-

Max Printing Width:

-

930mm

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

5.2*1.85*3.1m

-

Weight:

-

5200 KG

-

Max Unwinding Diameter:

-

1400mm

-

Max Rewinding Diameter:

-

1400mm

-

Printing speed:

-

5-120m/min

-

Printing Circumference:

-

254--508mm

-

Max Web Width:

-

950mm

-

Max Printing Width:

-

930mm

main features

1. Using ceramic anilox rollers for ink transfer.

2. Both feeding and receiving are controlled by magnetic powder brakes and clutches (or optional Japanese Mitsubishi automatic tension controllers).

3. Each printing unit adopts 360 ° circumferential plate alignment adjustment.

4. Each printing unit has a set of infrared drying devices.

5. Randomly equipped with a set of die-cutting stations to complete printing die-cutting in one go.

6. When parking, the ink roller can automatically detach and operate at low speed to prevent ink from drying out.

7. The main motor adopts variable frequency stepless speed regulation.

8. Paper supply from the cylinder, printing, polishing, automatic infrared drying, laminating, die-cutting, and winding are completed in one go. It is the most ideal model for printing commercial bills and high-end adhesive trademarks by various printing factories.

|

Model

|

SY-450

|

|

Max Unwinding Diameter

|

1400mm

|

|

Max Rewinding Diameter

|

1400mm

|

|

Printing Circumference

|

254--508mm

|

|

Max Web Width

|

950mm

|

|

Max Printing Width

|

930mm

|

|

Power supply

|

380V 3PH 50HZ

|

|

Printing Speed

|

5-120m/min

|

|

Plate thickness

|

1.7mm

|

|

Tape thickness

|

0.38mm

|

|

Thickness of paper

|

40-400g

|

|

Size

|

5.2*1.85*3.1m

|

|

Weight

|

About5200kgs

|

Printing Unit

.

Printing station comes with ink rubber roller, ceramic anilox cylinder, printing plate cylinder, scrapper blade and ink

container.helical gear

container.helical gear

UV dryer system

The supporting equipment of the printing equipment can provide the efficiency and effect of the finished printing products.

Web Guide System

lt is high-precision and is specially used to track material edge. lt is suitable for automatic control of rectifying deviation paper moving and make paper move straightly

Control Panel

Control panel with good quality switches,tempreture controller,dis-tributor controller and pressing roller controller.And all the operation of machine can be easily finished by this panel

Hot Searches