- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

1200

-

Dimension(L*W*H):

-

500X500X1100MM

-

Dispensing unit capacity:

-

50ml and 250ml

-

Sprayer traverse:

-

250mm

-

Fluid viscosity range:

-

1-50 mPas

-

Dispensing rate:

-

1-10ml / sec

-

plate:

-

250 X 250mm

-

keyword:

-

Spray pyrolysis machine

-

Certification:

-

CE/TUV

Quick Details

-

Machine Type:

-

coating

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CYKY

-

Voltage:

-

220V

-

Power:

-

1200

-

Dimension(L*W*H):

-

500X500X1100MM

-

Dispensing unit capacity:

-

50ml and 250ml

-

Sprayer traverse:

-

250mm

-

Fluid viscosity range:

-

1-50 mPas

-

Dispensing rate:

-

1-10ml / sec

-

plate:

-

250 X 250mm

-

keyword:

-

Spray pyrolysis machine

-

Certification:

-

CE/TUV

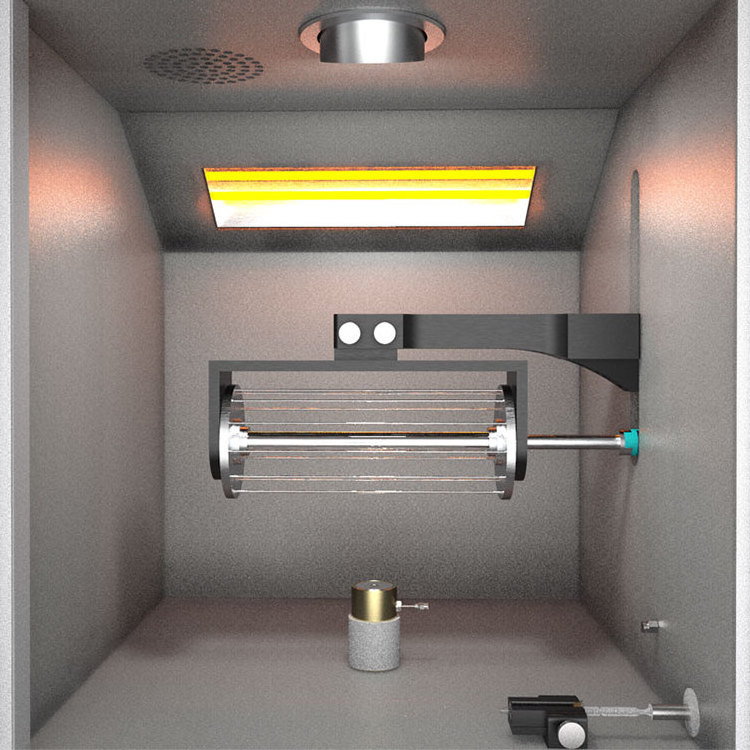

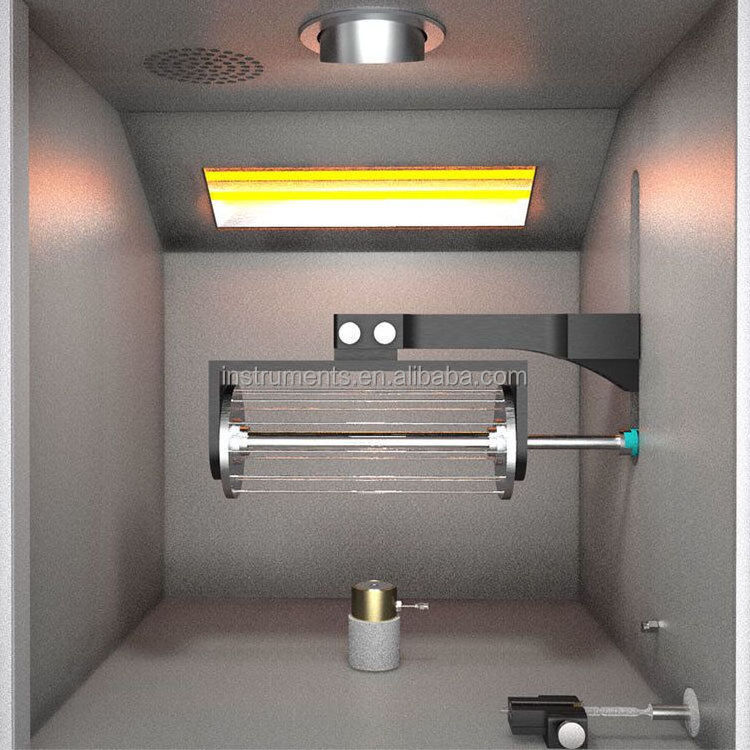

Large Floor-Stand Automatic Ultrasonic Spray Pyrolysis Coating Unit with 10"x10" 500oC Heating Plate

is the latest model . It is the larger version that provides expanded capacity and increased travel area for the spray head. This also provides a larger heating platform to spray coat substrates that are larger than the standard application. This model uses a fresh new design that enables the user to carry out the spray coating process in a more convenient and efficient manner. Also, it can be separated from the bottom shelf section for use as a table top unit. This unit also provides for Nitrogen purging of the enclosure. The parameters of the ultrasonic spray pyrolysis ( USP) equipment, like dispensing rate of the solution and the speed of spray head movement, can be precisely controlled by program. A positive displacement pump controlled by the stepper motor and microprocessor is used to dispense solution as per requirement. The ultrasonic spray head provides thinner particle coating and its movement is controlled by the stepper motor driven linear stages in X and Y direction to ensure uniform coating. The temperature of the substrate heater plate is controlled independently through a dedicated controller.

Spray pyrolysis is a process in which a thin film is deposited by spraying a solution on a heated surface, where the constituent reacts to form a chemical compound. The process is particularly useful for the deposition of oxides and has long been a production method for a long period for applying a transparent electrical conductor of Tin oxide (SnO2) or Stannic oxide to the glass. Now is popular to prepare perovskite solar cell.

|

Power Input |

Single phase 208 - 240VAC, 50/60Hz |

|

Actuator |

Stepper motor, 24VDC |

|

|

Three Spray heads are included: Ultrasonic spray head: for thinner film coating Compressive air spray: for thick film 20ml Syringe Pump with compressive air for the expensive solution of the thick film. Dispensing unit capacity: 50ml & 250ml ( two containers included ) Dispensing rate: 1-10ml / sec. adjustable via software. One brand new laptop computer or one Microsoft Surface Pro with pre-installed software is available for controlling. |

|

Sprayer

|

Ultrasonic atomizer nozzle: 40 KHz, 130W Producing a fine spray of droplets of 50 microns average size Fluid viscosity range: 1 - 50 mPa·s (cP) Sprayer traverse: X - Y 250mm max. Drive speed X axis (min-max): 10-800mm / sec Drive speed Y axis (min-max): 1-12mm / sec |

|

Pressure Regulator & Gauge

|

Pressure regulator with digital gauge is installed on the machine for precise air pressure control. Digital pressure gauge is operated by 3V lithium battery ( included ) |

|

Air Compressor |

Compressed air with a pressure of ~ 4 bar is required for normal operation of the unit One Compact air compressor is included for immediate use |

|

Substrate base plate |

Dimension: 250 X 250mm Max. temperature: 500°C Digital temperature controller |

|

Communication Port |

RS232 |

|

Warranty |

One year limited with lifetime support |

|

Compliance |

CE certified |

1. Factory prices with the best quality.

2. One year free-of-charge maintenance for all the dental equipment

3. Customized service for special demand

4. Fast and flexible delivery, by sea, by air, by express

5. Quick response within 24 hours

How to order

1. If you are interested in our products, please tell us the model number and quantity.

2. We will make a proforma invoice for your order.

3. We will deliver the product ASAP on receipt of the payment

Guarantee

1. Guarantee for one year after shipment.

Payment

1. Western Union

2. PayPal

3. Secure Payment through Alibaba

4. Telegraphic transfer

5. L/C