- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

300 KG, 300kg

-

Name:

-

automatic valve bag packing machine

-

Capacity:

-

5-7t/h

-

Weighing device:

-

Micro-computer

-

Weighing Scope:

-

10~60kg, adjustable on panel.

-

Measuring accuracy:

-

±0.2-0.4%

-

Bag weight qualified rate:

-

>95%

-

Air Requirements:

-

0.4-0.8MPa ( dry compressed air)

-

Operating temperature:

-

0℃~50℃

-

Storage temperature:

-

-20℃~60℃

Quick Details

-

Power:

-

220V50hz

-

Place of Origin:

-

China

-

Brand Name:

-

YISHANG

-

Weight:

-

300 KG, 300kg

-

Name:

-

automatic valve bag packing machine

-

Capacity:

-

5-7t/h

-

Weighing device:

-

Micro-computer

-

Weighing Scope:

-

10~60kg, adjustable on panel.

-

Measuring accuracy:

-

±0.2-0.4%

-

Bag weight qualified rate:

-

>95%

-

Air Requirements:

-

0.4-0.8MPa ( dry compressed air)

-

Operating temperature:

-

0℃~50℃

-

Storage temperature:

-

-20℃~60℃

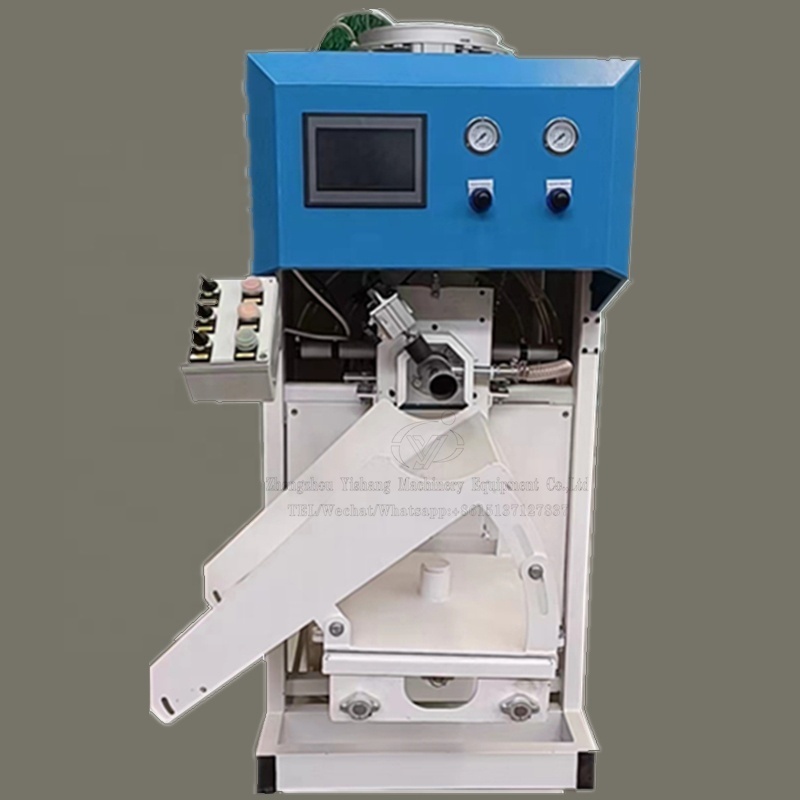

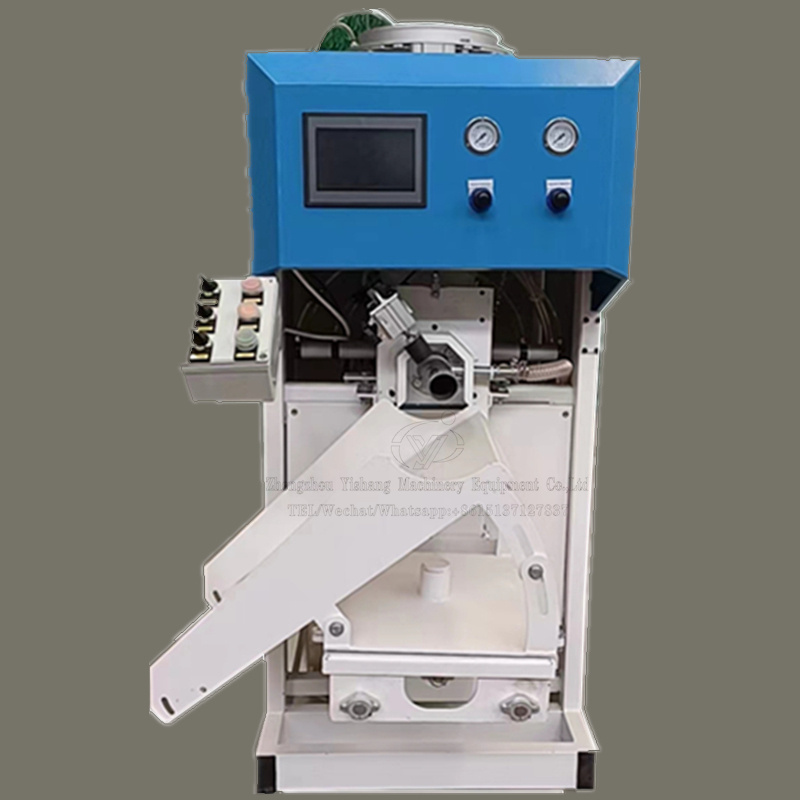

Air floated valve bag dry mortar packing machineger/packer

Overview:

Air floated valve bag dry mortar packing machine , The microcomputer system of the equipment is produced by industrial components and STM process. It has the advantages of small size, strong function, high reliability and good adaptability. It integrates weighing control with unique anti-interference ability and can be used in harsh environment for a long time.

Scope of application

Suitable for packing all kinds of dry mortar and thermoplastic road marking paint.

Technical specification:

a. Ambient temperature: -5 ° C to +40 ° C

b. Access dry air pressure: 0.6 ~ 0.8MPa

c. Power supply: AC220V

d. Equipment dimensions: length, width and height 1000mm*670mm*1660mm.

e. Power consumption of packaging machine, 20W

f. Loading accuracy +0.5kg

g. discharging speed: 5 s / 25 kg / 1 PC, 10 s / 50 kg / 1 PC, the material is different,The data will change

h. Output varies according to different materials, generally about 8T/h

I. An air compressor with a displacement of 0.9m³/min is required

Precautions for safe use:

Sensors have been installed on the equipment, and electric welding operations on the equipment should be avoided as far as possible. If it is necessary to weld, the welding position should be near the iron to ensure that the sensor is not affected by any welding current. If the sensor has been connected to the controller, then all welding operations on the mechanical component part of your equipment are absolutely not allowed. Ensure that the power supply entering the device is stable and without interference; otherwise, the device will be damaged and the control system will be interfered.

Ensure that the air source into the packaging machine is dry, otherwise it will bring many problems to the equipment - plugging, solenoid valve loss, cylinder pollution and so on. The packing machine must be placed smoothly without shaking, and the upper pneumatic butterfly valve must be firmly connected.

Equipment users must ensure to clean equipment dust twice a day. Must be equipped with dust removal equipment, improve the working environment.

The weighing body ensures that the weight is checked at any time from time to time to ensure the accuracy of weighing and avoid the product weight in batches out of tolerance

A dvantages :

1. Fast packing,easy to operate.

2.No need for secondary sealing.

3.Long-term work , good reliability.

4.Weighting accuracy ,shorten working hours

5.Weighting hopper adopts resistance strain sensor ,Convenient to debug.

6.Measurement standard adopts international Digital calibration ,high accuracy.

7.Electrical control adopts one contractor ,extreme high reliability

|

M odel |

The air floating type valve mouth packing machine |

|

T ype |

a utomatic weighing |

|

Packaging scope |

5-50kg/bag |

|

Workers required |

1-2 persons |

|

Filling speed |

7-10s/bag |

|

Capacity |

5-8T/H |

|

W orking method |

M anual doing, Automatic weighing |

|

T otal power |

220V |

|

T otal weight |

300 kg |

|

W orking area |

1070mm*670mm*1900mm(L*W*H) |

ZHENGZHOU YISHANG MACHINERY EQUIPMENT CO.,LTD

Web: www.drymortarmachinery.com

zzyishang.en.alibaba.com

Tel : +86 15137127837

WeChat ID: +86 15137127837