- Product Details

- {{item.text}}

Quick Details

-

Appearance:

-

Flowing liquid silicone rubber

-

Color:

-

white or translucent

-

Item:

-

XB mould making series

-

Mixing ratio:

-

100:3

-

Certificate:

-

SGS, RoHS

-

Hardness:

-

30 shore A

-

Original of raw materials:

-

imported raw materials

-

Sample:

-

1kg for free

-

trial order:

-

available

-

Factory location:

-

Dongguan, Guangdong

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sibetter Silicone

-

Model Number:

-

RTV XB-730#

-

Appearance:

-

Flowing liquid silicone rubber

-

Color:

-

white or translucent

-

Item:

-

XB mould making series

-

Mixing ratio:

-

100:3

-

Certificate:

-

SGS, RoHS

-

Hardness:

-

30 shore A

-

Original of raw materials:

-

imported raw materials

-

Sample:

-

1kg for free

-

trial order:

-

available

-

Factory location:

-

Dongguan, Guangdong

Prices RTV 2 Concrete Imprint Moulds Making Silicone

1. Description of

Prices RTV 2 Concrete Imprint Moulds Making Silicone

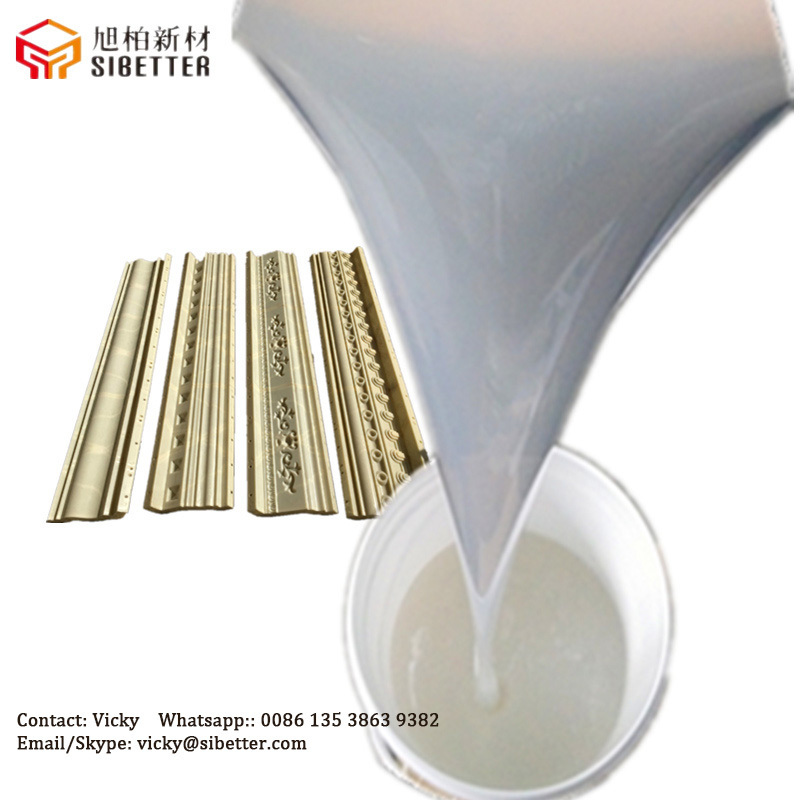

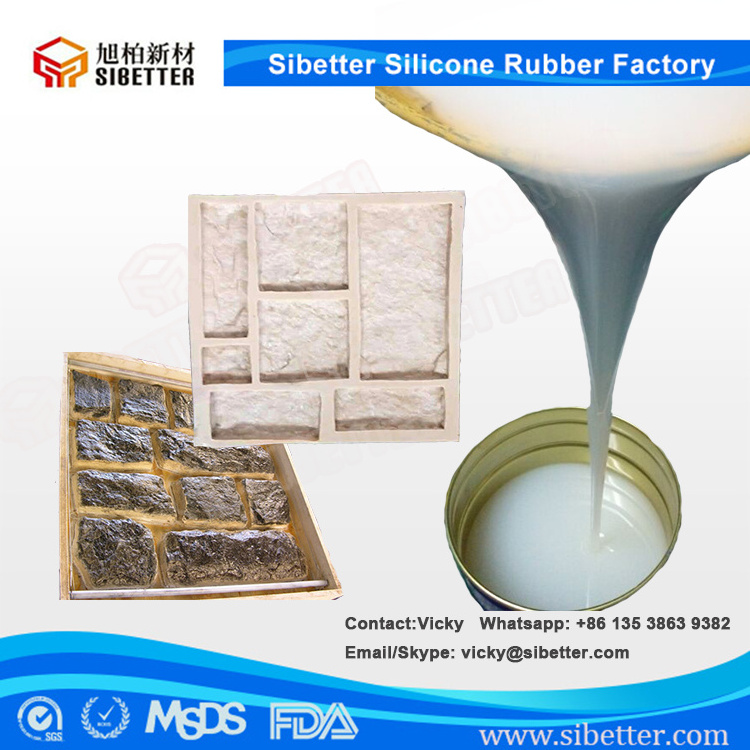

Prices RTV 2 Concrete Imprint Moulds Making Silicone is general called two-component room temperature vulcanization silicone rubber with excellent fluidity and good operational perormance, an elastic silicone rubber mold will be obtained with resistance to deformation, high-temperature, acid and alkali and expansion.

2. Applications of

Prices RTV 2 Concrete Imprint Moulds Making Silicone

Liquid RTV silicone rubber to make mould is primarily intended for poly resin crafts, PU crafts, PU resin crafts, gypsum crafts, unsaturated resin crafts, lighting and candles crafts, plastic toy, stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

3. Features of

Prices RTV 2 Concrete Imprint Moulds Making Silicone

(1) Liquid RTV Silicon for template with SGS and RoHS approval

(2) Curing agent arrange together as free charged

(3) In liquid form and in various colors

(4) With an exceptional fluidity and good operability.

(5)Temperature and deformation resistance as well as low shrinkage.

(6) High duplication times.

(7) Sample orders are available

4. Datesheet of

Prices RTV 2 Concrete Imprint Moulds Making Silicone

| Model NO· | XB-625 | XB-630 | XB-730 | XB-735 |

| Mixing Ratio (by weight) | 1:1 | 1:1 | 100:3 | 100:3 |

| Appearance/Color | Translucent | Translucent | White | White |

| Hardness (Shore A) | 25±2 | 30±2 | 30±2 | 35±2 |

| Mixed viscosity(mPa·s) | 2000 | 4000 | 20000 | 20000 |

| Working Time(at 23℃/75℉, MINS) | 30 | 30 | 30 | 30 |

| Curing Time(at 23℃/75℉, HRS) | 2~5 | 2~5 | 2~5 | 2~5 |

| Tensile strength, Mpa | ≥5 | ≥5 | ≥4 | ≥4 |

| Tear strength, KN/m | ≥20 | ≥15 | ≥25 | ≥20 |

| Shrinkage, % | <0.1 | <0.1 | <0.2 | <0.2 |

| Elongation at break,% | ≥400 | ≥400 | ≥480 | ≥480 |

Besides the mixing ratio and price, the largest difference between the condensation cure silicon and platinum cure silikon to make the concrete mold, is the shrinakge.

Why is the surface of the finished silicone mould unsmooth and figured

There maybe three reasons for this:

1. It is because the surface of the mother mould itself is not perfect;

2. the mother mould has not been grinded or polished before the further operation

3. the release agent has not been sprayed on the surface of the mother mould evenly

So when we make silicon moulds, firstly we should choose a prefect mold and polish it, then spray the release agent evenly on the product. In this case, the problem can be avoided.

We have own lab with the experienced&professional R&D and production team as well as advanced devices. Here show only parts of the whole testing.

If you need any further information about the liquid silicone rubber, pls feel free to contact Vicky:

E-mail: vicky(at)sibetter(dot)com

SKype: vicky(at)sibetter(dot)com

Mobile/whatsapp: +86-135 3863 9382

Tel: +86-0769-23077653

Fax: +86-0769-23077651