- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

China

-

Brand Name:

-

CNMI

-

Model Number:

-

TC130

-

Type:

-

TC130A TC130B

-

Product name:

-

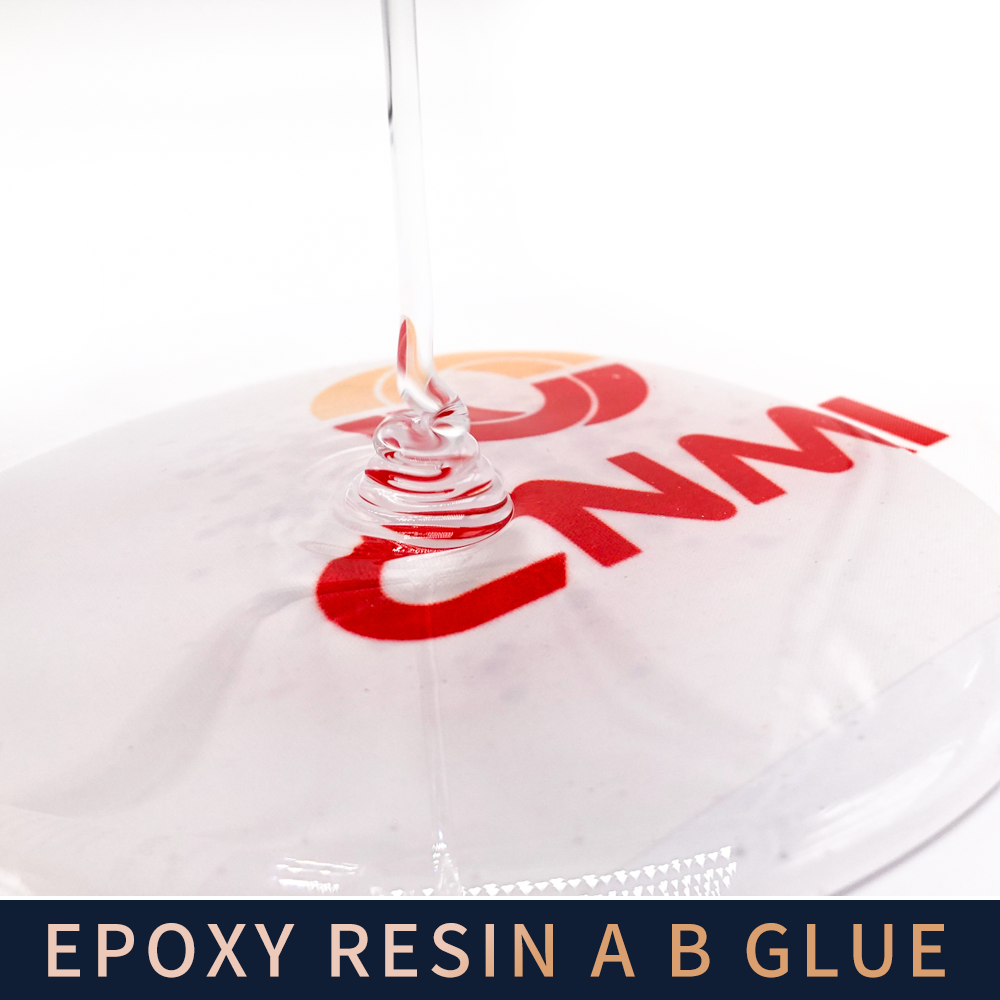

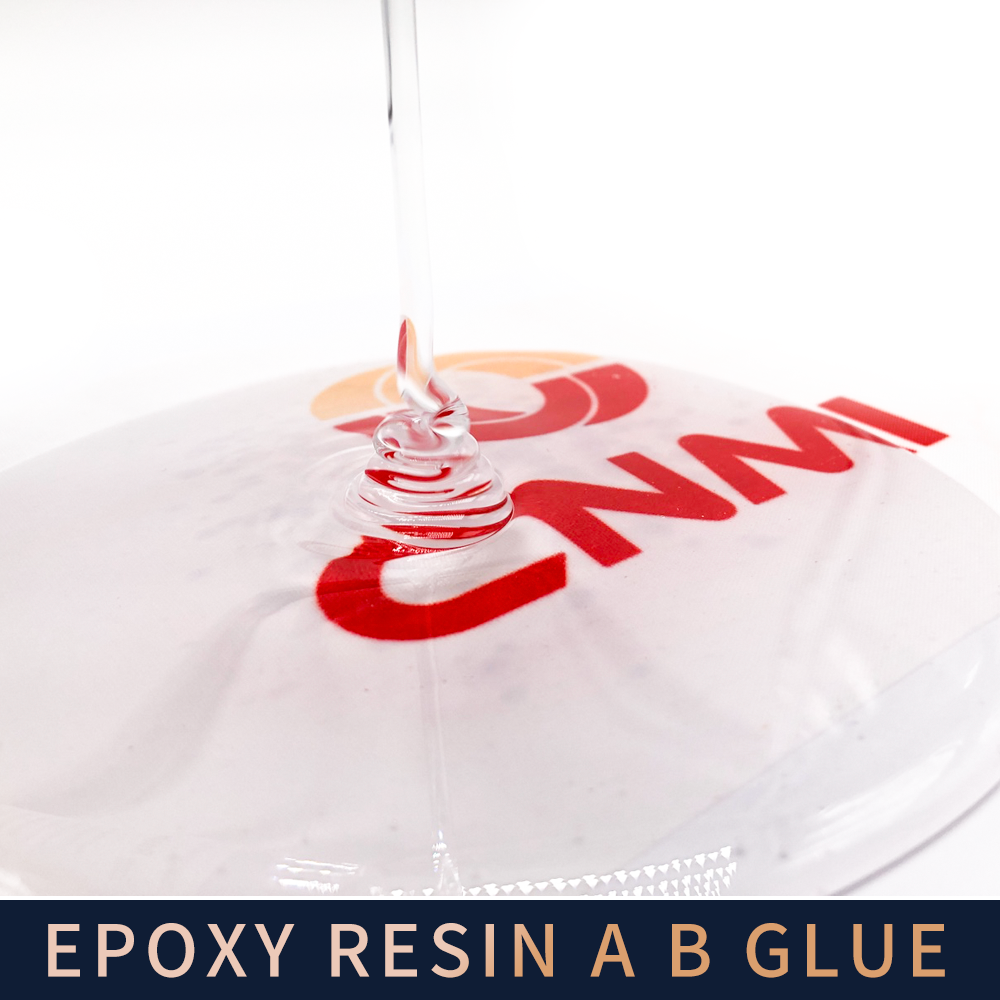

Flexible Epoxy Resin

-

Material:

-

Pure Epoxy

-

Color:

-

Transparent

-

Application:

-

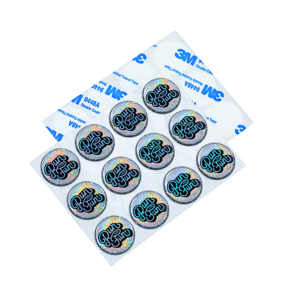

Keyring 3D Domed Stickers Label

-

Appearance:

-

Liquid Flexible

-

Packing:

-

Bottle

-

Shelf life:

-

12 Months

-

Advantage:

-

Environment Friendly

-

Keywords:

-

Flexible Epoxy Resin

-

Ration:

-

1:1 by Weight

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

Epoxy Resin AB Glue

-

MF:

-

C21H25ClO5

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

China

-

Brand Name:

-

CNMI

-

Model Number:

-

TC130

-

Type:

-

TC130A TC130B

-

Product name:

-

Flexible Epoxy Resin

-

Material:

-

Pure Epoxy

-

Color:

-

Transparent

-

Application:

-

Keyring 3D Domed Stickers Label

-

Appearance:

-

Liquid Flexible

-

Packing:

-

Bottle

-

Shelf life:

-

12 Months

-

Advantage:

-

Environment Friendly

-

Keywords:

-

Flexible Epoxy Resin

-

Ration:

-

1:1 by Weight

CNMI Clear Crystal Epoxy Resin AB Glue TC130 1:1 Soft Resin Anti UV Flexible Epoxy Resin for Keyring 3D Domed Stickers Label Very Softness

Product Description

What is Epoxy?

Epoxy refers to any of the basic components or cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups.

Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing.

Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, use in electronics/electrical components/LEDs, high tension electrical insulators, paint brush manufacturing, fiber-reinforced plastic materials, and adhesives for structural and other purposes.

Epoxy refers to any of the basic components or cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups.

Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing.

Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, use in electronics/electrical components/LEDs, high tension electrical insulators, paint brush manufacturing, fiber-reinforced plastic materials, and adhesives for structural and other purposes.

|

Specification

(1) |

Epoxy Resin

|

TC130-A

|

Standard

|

|||

|

|

Appearance

|

Colorless Transparent Liquid

|

-------

|

|||

|

|

Viscosity (mPa.s 25℃)

|

2000-4000

|

GB/T 22314-2008

|

|||

|

|

Epoxy equivalent (eq/100g)

|

190-200

|

GB/T 4612-2008

|

|||

|

|

Hardener

|

TC130-B

|

Standard

|

|||

|

|

Appearance

|

Colorless Transparent Liquid

|

--------

|

|||

|

|

Viscosity (mPa.s 25℃)

|

10-100

|

GB/T 22314-2008

|

|||

|

Note:Typical performance should not be considered as product specifications

|

|

|

|

|||

|

Mixing and Processing

|

The resin system shall be mixed in the following proportions

|

|

|

||

|

|

Weight Ratio

|

TC130-A

|

TC130-B

|

||

|

|

Weight Ratio

|

100

|

100

|

||

|

Mix Viscosity (mPa.s 25℃)

|

100-200CPS

|

|

|

||

|

Processing time 25℃

|

50-80min

|

|

|

||

|

Cure Condition

|

25℃/24-72hours/ 60℃ 2hours

|

|

|

||

Product Application

Product Advantage

We have china biggest doctor research station. We can supply OEM for packing, and customized product.

Our products have below advantages:

1. Both the Epoxy Resin and Hardener is totally Clear, Crystal and Colorless.

2. The ratio is 1:1. (Easy Working)

3. Both Epoxy and Hardener are no dangerous. There is FREE VOC, NO BPA.

4. We add HALS, which is UV Protection.So that it doesn't change yellow.

5. Scratch Resistance, Heat Resistance, Electrical Resistance, Waterproof.

6. Antibacterial Techonology, approved ASTM D 4236, EN71, make our resin more safe.

7. Excellent Flexible, Softness, NO Cracking.

The most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever.

We sincerely hope to establish business relations with your esteemed corporation.

1. Both the Epoxy Resin and Hardener is totally Clear, Crystal and Colorless.

2. The ratio is 1:1. (Easy Working)

3. Both Epoxy and Hardener are no dangerous. There is FREE VOC, NO BPA.

4. We add HALS, which is UV Protection.So that it doesn't change yellow.

5. Scratch Resistance, Heat Resistance, Electrical Resistance, Waterproof.

6. Antibacterial Techonology, approved ASTM D 4236, EN71, make our resin more safe.

7. Excellent Flexible, Softness, NO Cracking.

The most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever.

We sincerely hope to establish business relations with your esteemed corporation.

Hot Searches