- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Feiya710302 metal stamping supplies

-

Mold material:

-

XW-42, SKD11, SKH-9, ASP23, CD650, S45C etc

-

Tooling Life:

-

300 Million Times

-

Product material:

-

copper, iron, aluminum, metal,etc.

-

Die Type:

-

2-Plate Die,3-Plate Die,Module Die

-

Mould cavity:

-

1 rows 1 out,2 rows 2 out,4 rows 8 out

-

Stamping Speed:

-

60-1000SPM/min

-

Drawings:

-

Received 2D/3D

-

Demention tolerence:

-

+/-0.03mm stamping mold

-

Size:

-

According to your drawings

-

Keyword:

-

progressive metal stamping terminal mold

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Jiangsu, China

-

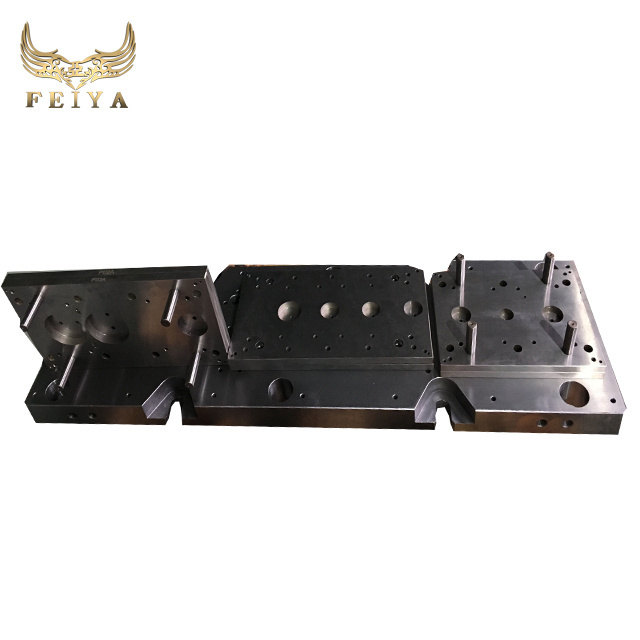

Brand Name:

-

FYSD metal stamping die

-

Model Number:

-

Feiya710302 metal stamping supplies

-

Mold material:

-

XW-42, SKD11, SKH-9, ASP23, CD650, S45C etc

-

Tooling Life:

-

300 Million Times

-

Product material:

-

copper, iron, aluminum, metal,etc.

-

Die Type:

-

2-Plate Die,3-Plate Die,Module Die

-

Mould cavity:

-

1 rows 1 out,2 rows 2 out,4 rows 8 out

-

Stamping Speed:

-

60-1000SPM/min

-

Drawings:

-

Received 2D/3D

-

Demention tolerence:

-

+/-0.03mm stamping mold

-

Size:

-

According to your drawings

-

Keyword:

-

progressive metal stamping terminal mold

Optimize of mold cost and best use is our priority.

We accept: 2D--dxf & dwg & pdf; 3D--UG files, like STP, IGS, X_T., Prt.

Details:

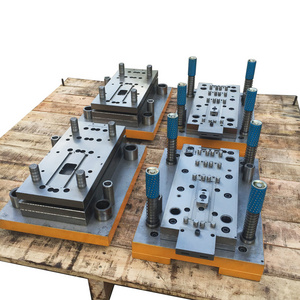

Specifications

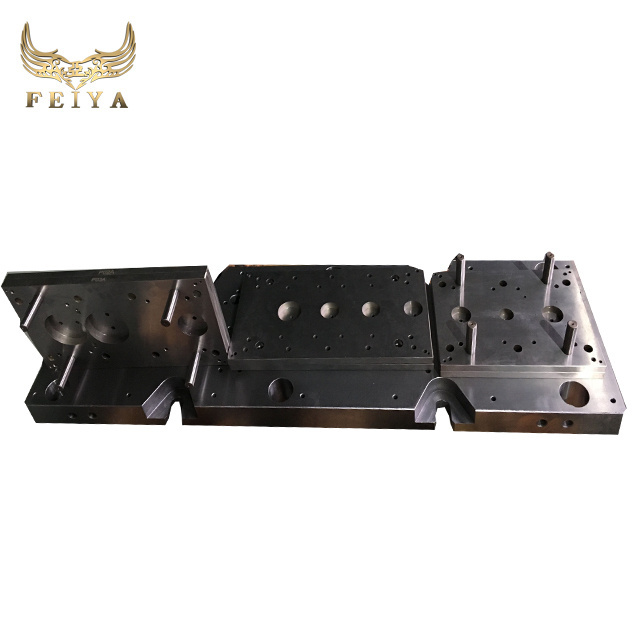

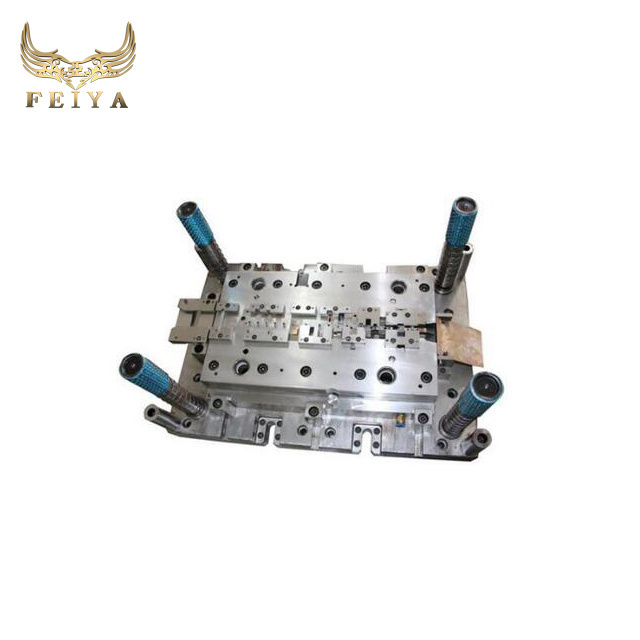

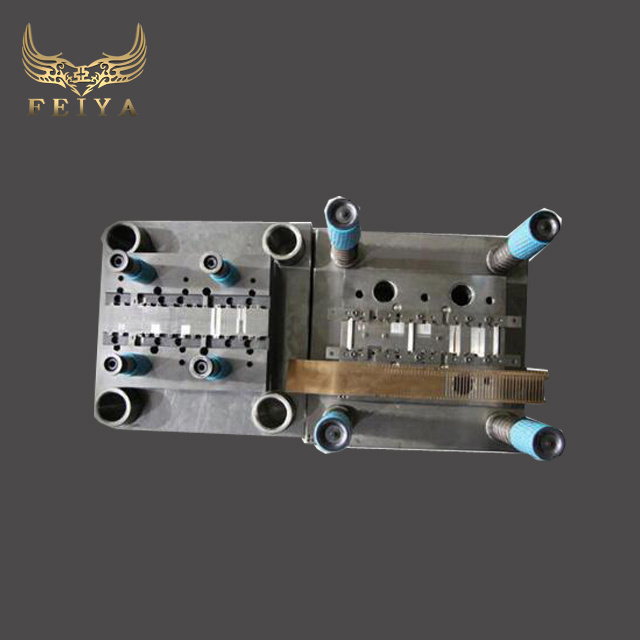

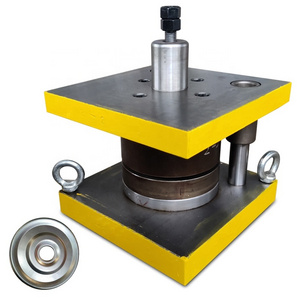

Mold 2D + 3D drawing Design:

|

Product name |

High speed progressive metal stamping precision battery terminal mold |

|

Tooling steel material |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: Carbide(CD650,V3,KD20), ASP-23, ASP-60, S55C---45#55, SKD11. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Die concept |

2-Plate Die, 3-Plate Die, Module Die |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 50 Million to 300 Million Times |

|

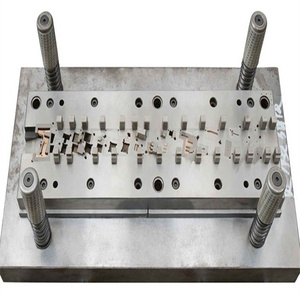

Stamping Product |

PC Terminal, Power terminal, Press-Fit Terminal, Lead frame, SIM Spring, Connector Shield, Battery, Metal USB shell, custom stamping. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, plating, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system ). |

|

Production |

P ilot Run production and molding production can be provided. |

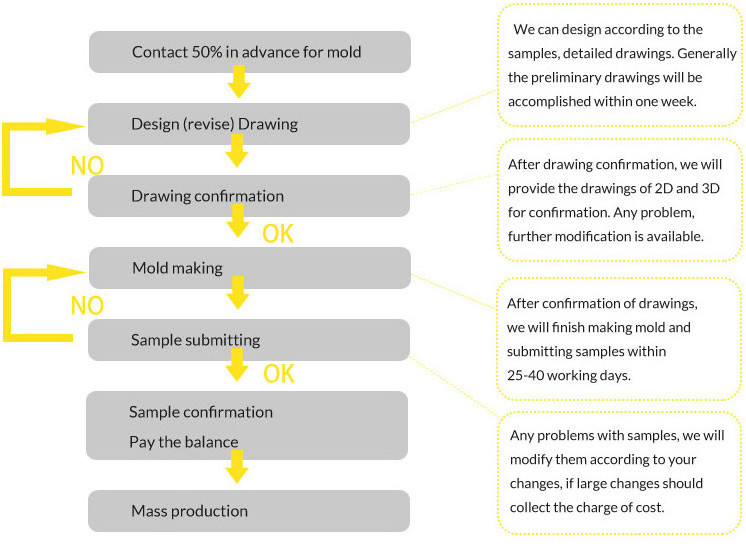

Product Flow

How to Customized a Mold?

A) Before sales Service

- 24hour online consult

- Sample support

- Detailed technical 2d and 3d drawing design

- Free pick up at hotle/aitport to visit Feiya factory

- Qick and profession response on quotation and technial

B) Production period service

- Technical 2d and 3d drawing submit to double check details and discussion

- Quality inspection report submit

- Installation solution and maintenance instruction

C) After sales service

- Provide the usage advice and Guide, remote assistance

- 15 Years quality Guarantee

- Any quality problems replace freely

Our Partner

Our stamping products

Kunshan Feiya Precision Moulding Co., Ltd.

Contact name

: Jenny zhou

Tel: +86-512 5519 1682 Fax: +86-512 5519 1683

Mobile: +86-13773151567 Skype: 951050723

qq.com

Wechat:13773151567 Email: fly12

ksfeiya.cn

Web: www.feiyamold.com

Add: No. 883, Wulian Rd, Chengbei, Yushan Town, Kunshan city, Jiangsu, China.