- Product Details

- {{item.text}}

Quick Details

-

Power:

-

According to the model

-

Weight:

-

1000

-

Dimension(L*W*H):

-

According to the model

-

Equiped:

-

Electrical control box

-

Application:

-

DO,FO,LO,Waste oil treatment

-

Adventage:

-

Long time with low vibration

-

Sludge discharge:

-

Automatically and fully

-

Speed:

-

High

-

Operation:

-

Continuous

-

Shape:

-

single or module

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kingreat, Kingreat

-

Voltage:

-

220,380,440,460V

-

Power:

-

According to the model

-

Weight:

-

1000

-

Dimension(L*W*H):

-

According to the model

-

Equiped:

-

Electrical control box

-

Application:

-

DO,FO,LO,Waste oil treatment

-

Adventage:

-

Long time with low vibration

-

Sludge discharge:

-

Automatically and fully

-

Speed:

-

High

-

Operation:

-

Continuous

-

Shape:

-

single or module

Oil Solid Separation Separator Famous Fuel Oil Purifier

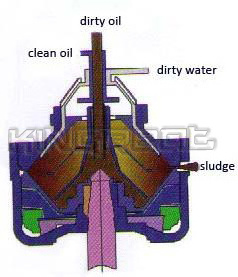

Diesel Oil/HFO/LO/FO disc separator is mainly used to remove water and mechanical impurities from fuel oil, lubricating oil and other mineral oil in marine diesel engine unit and land-used diesel generator unit of power station so as to reduce wear of the diesel engine and other machine, and prolong engine life. The model is also used to separate two unsolvable liquids with different specific gravity or remove small amount of solid particle from liquid.It is divided into 2phase solid-liquid separator and oi-water-impurity 3phase separator.They are workable in land and ship,we have the CCS certificate to certify its function and usage. There are different discharge types of the oils,manually,partial,fully discharged,variable discharge etc which depends on the different materials.commonly,we define the capacity as density of 0# diesel oil ,and we have a chart to help you find out the exact processing capacity of your needs. We are not only provide the single oil separator,but also the whole unit containing the pumps,valves,heats,pipes and so on.

Disc separator is vertical centrifuge. The drum is installed on the upper side of the vertical shaft. Driven by the motor, it will rotate at a high speed through the gearing. Inside the drum there is a group of dish parts overlaying each other – disc. There is very small gap between the disc. Suspension (or emulsion) is fed into the drum through the inlet in the middle of the drum. When the suspension (or emulsion) flows through the gap between the disc, under the action of the centrifuge, the solid particles (or droplets) go down to the disc in the formation of sediment (or liquid layer). Along the disc surface, the sediment slides out of the disc and accumulates at the part with the largest diameter inside the drum. After the separation, the liquid is discharge out of the drum from the drain outlet. The role of the disc is to reduce the sediment distance of solid particles (or droplets) and enlarge the sediment area of the drum. With the disc inside the drum, the capacity of the separator is improved greatly. The solid gathering inside the drum is manually removed by taking apart the drum after power off, or discharges from the drum through the slag-off part with the separator power on.

1. Overload over heat protection

2. High rotating speed

3. Accurate dynamic balancing

4. Long time with low vibration

5. Safety and security

6. Continuous working

Condition for mineral oil separation and actual capacity (refer to the chart)

|

Oil types |

Heavy diesel oil |

Lubrication oil |

|||||||

|

SAE30,40 |

Detergence oil |

Steam turbine oil |

|||||||

|

Kinematical viscosity(mm2/s) |

13 |

20.5 |

36.2 |

80 |

100-120 |

61.2-74.8 |

|||

|

50℃ |

40℃ |

40℃ |

|||||||

|

Density/(kg/m3)(20℃) |

<900 |

900-991 |

880-900 |

<900 |

|||||

|

Separating temperature (℃) |

40 |

60 |

80 |

80-95 |

|||||

|

Recommended capcity (L/h) |

900-10000 |

300-7000 |

|||||||

|

|

|||||||||

|

Oil types |

Fuel oil |

||||

|

Fuel oil |

Heavy fuel oil |

||||

|

Kinematical viscosity(mm2/s |

1.9-5.5 |

5.5-24 |

120 |

180 |

380 |

|

40℃ |

50℃ |

||||

|

Density/(kg/m3)(20℃) |

<900 |

900-991 |

|||

|

Separating temperature (℃) |

Normal temperature,40-60degree best |

90-98 |

|||

|

Recommended capacity (L/h) |

From 650L/H to 25000L/H depends on different oil and working temperature. |

||||