- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

25 MPa

-

Heating Power (kW):

-

98 kW

-

Air Comsumption(L/min):

-

2 L/min

-

Water Comsumption(L/min):

-

4 L/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Plastic Cup Thermoforming Making Machine

-

Voltage:

-

380/415 V

-

Dimension(L*W*H):

-

3*1.2*1 M

-

Weight (T):

-

5 T

-

After Warranty Service:

-

Video technical support

-

Name:

-

plastic plates and cups making machines

-

Usage:

-

Plastic Forming Machine

Quick Details

-

Max.Forming Height(mm):

-

300 mm

-

Forming Width (mm):

-

3000 mm

-

Forming Length (mm):

-

3000 mm

-

Air Pressure(MPa):

-

25 MPa

-

Heating Power (kW):

-

98 kW

-

Air Comsumption(L/min):

-

2 L/min

-

Water Comsumption(L/min):

-

4 L/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Plastic Cup Thermoforming Making Machine

-

Voltage:

-

380/415 V

-

Dimension(L*W*H):

-

3*1.2*1 M

-

Weight (T):

-

5 T

-

After Warranty Service:

-

Video technical support

-

Name:

-

plastic plates and cups making machines

-

Usage:

-

Plastic Forming Machine

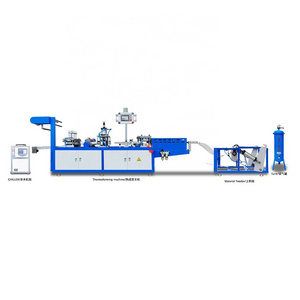

Most Popular Plastic Cup Making Machine

1.Introduction of Machine

HSC-660A thermoforming machine is a combination of mechanical, electrical and pneumatic components, and the whole system was controlled by micro PLC. It is operates with man-interface, which can works all by itself. It combines the material feeding, heating, drawing, forming, cutting into one process.

2.Main features Machine

I t is used for forming PP, PS, HIPS, PVC and PET plastic sheets, which can be widely used to produce all kinds of plastic boxes, containers and other plastic wares, such as ice-cream cups, milk cups chocolate package boxes, candy boxes and fast-food boxes etc .

3.Componets of Machine

| No. | Items | Qty. | Remark |

| 1 | Sheet Extruder | 1 Set | |

| 2 | Temperature Control | 1 Set | |

| 6 | Thermoforming Machine | 1 Set | |

| 3 | Mould | 1 Set | One Line Mould |

| 4 | Mould | 1 Set | Two Line Mould |

| 5 | Cup Stacker | 1 Set | |

| 6 | Air Comprossor | 1 Set | |

| 7 | Crusher | 1 Set | |

| 8 | Chiller | 1 Set | |

| 9 | Water Tower | 1 Set |

4.Main Technical Parameter Machine

| 1) Maximum forming area: 250*580mm | 2) Maximum forming depth: 120mm |

| 3) Maximum width rage of sheet: 300~600mm | 4) Thickness range of sheet: 0.2-2.5mm |

| 5) Maximum sheet roller diameter: 710mm | 6) Air pressure: 0.7Mpa |

| 7) Water consumption: 10 Liters/min | 8) Air consumption: 2000 Liters/min |

| 9) Manufacturing speed: 35mould/min | 10) Power: 3-N AC220V±15V 60HZ |

| 11) Heating motor power: 38KW | 12) Main motor power: 4KW |

| 13) Feeding motor power: 2.2KW | 14) Rewinding motor power: 0.55KW |

| 15) Weight: 4000kg | 16) Main machine(L*W*H): 3300*1650*2250(mm) |

| 17) Rewinder (L*W*H): 1250*800*1900(mm) | |

5.Pictures of Machine