- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

100 Mesh Stainless Steel Wire Mesh

-

Brand Name:

-

huanji

-

Product name:

-

304 / 304L / 316 / 316L Stainless Steel Wire Mesh

-

Usage:

-

Liquid Filter

-

Surface treatment:

-

Untreatment

-

Hole shape:

-

Square Hole

-

Weaving type:

-

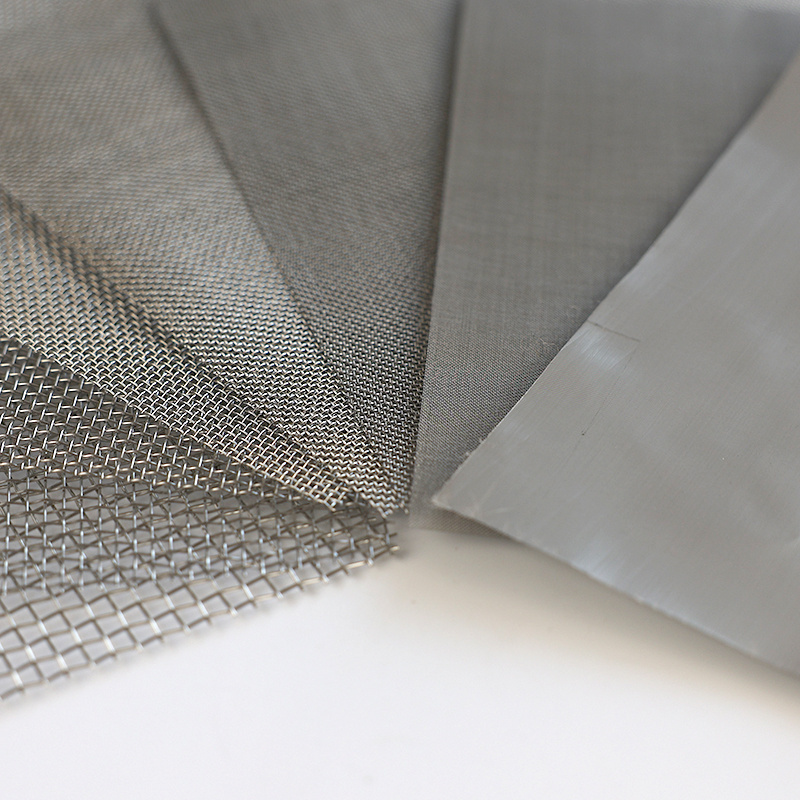

Plain/twill/dutch Weave 304 Stainless Steel Wire Mesh

-

Raw Material:

-

302 304 316 316L Stainless Steel

-

Aperture:

-

0.038mm~6.7mm

-

Keyword:

-

Weave Stainless Steel Wire Mesh

-

Sample:

-

Avaliable Sample

-

Width:

-

0.5m-2m

Quick Details

-

Material:

-

Stainless Steel

-

Type:

-

Weave Wire Mesh

-

Application:

-

Woven Wire Mesh

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

100 Mesh Stainless Steel Wire Mesh

-

Brand Name:

-

huanji

-

Product name:

-

304 / 304L / 316 / 316L Stainless Steel Wire Mesh

-

Usage:

-

Liquid Filter

-

Surface treatment:

-

Untreatment

-

Hole shape:

-

Square Hole

-

Weaving type:

-

Plain/twill/dutch Weave 304 Stainless Steel Wire Mesh

-

Raw Material:

-

302 304 316 316L Stainless Steel

-

Aperture:

-

0.038mm~6.7mm

-

Keyword:

-

Weave Stainless Steel Wire Mesh

-

Sample:

-

Avaliable Sample

-

Width:

-

0.5m-2m

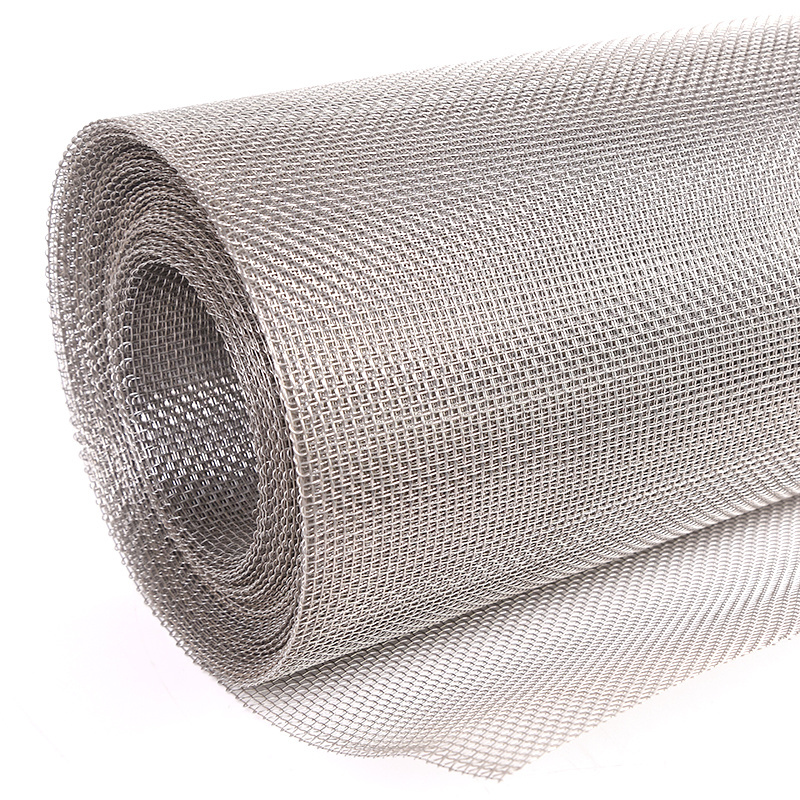

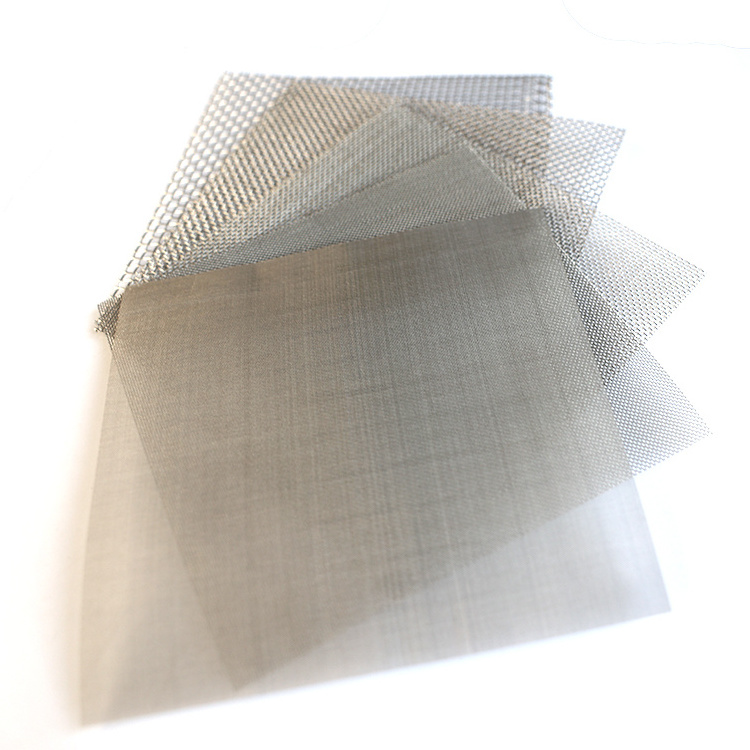

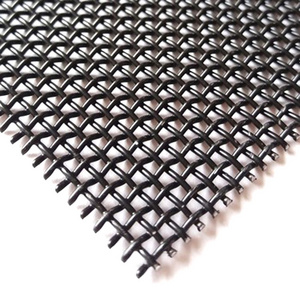

Product Display

Wire mesh, also known as wire cloth or wire fabric, is a versatile metal product that can be used effectively in countless applications globally. Popular uses for wire mesh include stainless steel wire mesh for filters, steel wire mesh for partitions, and PVC wire mesh for machine guards. From industrial to commercial applications, wire mesh is a common metal product that is used by many daily.

Wire mesh offers many benefits including:

-Widest range filtration, from over 6-inch aperture down to 1-micron nominal.

-High open area/flow rate.

-Closely controlled, accurate apertures.

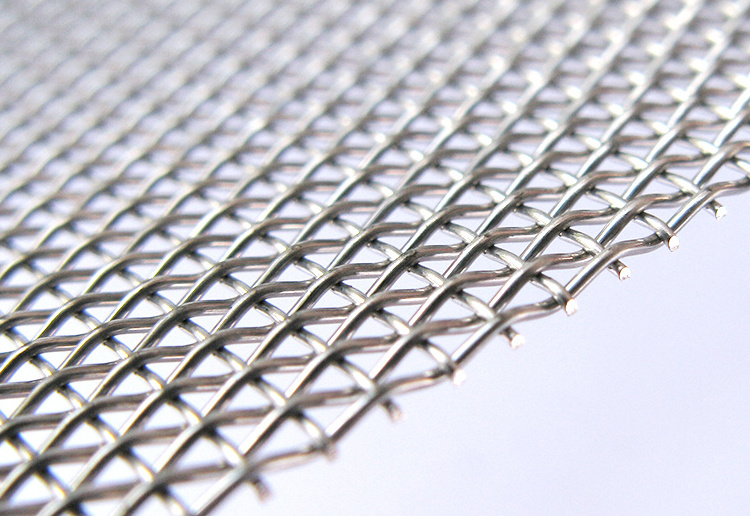

-Smooth surface - screening surface has no sharp edges, burrs or acute angles.

-Usable under high pressure.

-Flexible - ideal for forming rigid concave / convex shapes.

-High durability.

-Control of chemical/acid/ corrosion resistance using different metals.

-Special aperture requirements can be met without high tooling costs.

-The weaving process uses no punching, piercing or stretching operations that create stress-induced weaknesses.

-Suitable as upper for less rigid media.

-Stable under tension.

-Point contact only on the screened product allows freer screening and reduced binding.

-Hygienic characteristics and cleanability are specifically suitable for the food and pharmaceutical industries.

-Corrosion, abrasion and heat resistance.

-Highly aesthetic appeal for architectural applications.

Product packaging

Hot Searches