- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Ningbo, China

-

Brand Name:

-

KEFAI

-

Weight:

-

270KG

-

Power:

-

1.5KVA

-

Competitive:

-

Best Price

-

Performance:

-

High Qaulity

-

Stable:

-

High Efficiency

-

Durable:

-

Long Life

-

Enviromental:

-

Low Consuption

-

Digitalization:

-

PC&Network

-

Certification:

-

CE, CE&ISO9001

-

Euromap:

-

EU12, EU67

Quick Details

-

Warranty:

-

1 Year

-

Vertical Travel(mm):

-

{-4-1300mm}

-

Horizonal Travel(mm):

-

{-3-1550mm}

-

Place of Origin:

-

Ningbo, China

-

Brand Name:

-

KEFAI

-

Weight:

-

270KG

-

Power:

-

1.5KVA

-

Competitive:

-

Best Price

-

Performance:

-

High Qaulity

-

Stable:

-

High Efficiency

-

Durable:

-

Long Life

-

Enviromental:

-

Low Consuption

-

Digitalization:

-

PC&Network

-

Certification:

-

CE, CE&ISO9001

-

Euromap:

-

EU12, EU67

Product Description

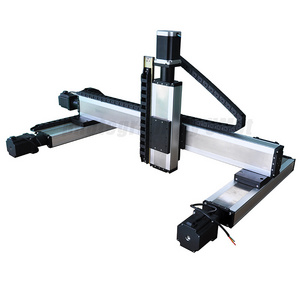

Specification

| Model | Unit | KAW-1100 | KAW-1300 | KAW-1500 |

| Type | Double section | Three-Axis Servo Robot | ||

| Vertical stroke | mm | 1100 | 1300 | 1500 |

| Crosswise stroke | mm | 1450 | 1550 | 1650 |

| Swing stroke | mm | 2300 | 2300 | 2500 |

| Drive system | - | X Y Z Axis Servo motor | ||

| Gripper rotation angle | o | 270 | 270 | 270 |

| Max load(with tool) | kg | 10 | 10 | 10 |

| Minimum takeout time | sec | 3 | 3 | 3 |

| Dry cycle time(without tool) | sec | 9 | 9.5 | 9.5 |

| Working air pressure | kgf/cm2 | 5--7 | 5--7 | 5--7 |

| Air consumption | NL/cycle | 25 | 25 | 25 |

| Power consumption | KVA | 1.5 | 1.5 | 1.8 |

| Power | AC | 220V 50/60Hz | 220V 50/60Hz | 220V 50/61Hz |

| Net weight | kg | 260 | 270 | 280 |

| Standard Function | |

| Midway runner release | Runner is released at a place different from product. |

| Descent during mold open | Used to shorten the mold cycle by starting the descending of arm on the way to mold open. |

| Mold close during arm ascent | Used to shorten the molding time by starting the mold closing on the way to ascent. |

| Plastic runner can be released at anyplace of the traverse axis | Runner is released at a place different from product. |

| Internal memory storage | Controller memory for mold program information. USB device for ease of program storage, even during normal operation, which is faster and more convenient. |

| Alarm(Buzzer)optional | The alarm lamp(Buzzer) is switched on a light when there is a alarm(error) in the robot. |

| Conveyor interface | Control conveyor functions. |

| Air nipper circuit | While cutting runner, use this function.(Scissor device is optional cost). |

| Fixed side/moving side switch | Injection molding machines is designed to eject product from the moving side normally. Use fixed-side/moving side function to suit for ejecting product from the side of moving side. |

| Vacuum confirmation circuit | While part need to use suction cup by vacuum, it can be confirmed by this circuit. |

| Mold area movement | Robot can move freely in the mold area to take out the product with barb or others. |

| Release or grip in mold area | Can release part or runner in mold area after grip the runner or absorbs the part. |

| Defective product reject circuit | Defective products are separated by interface signal from I.M.M. |

| Outside mold area stand-by | Robot can stand-by outside mold (outside the safety door) when robot end arm meets those mold obstructions. |

| Language selection | Language can be changed between Chinese and English. |

| Product extract posture control | Used to carry out posture action until arm ascent to a proper position to do the movement. In order to avoid collide with the safety door of IMM or the robot arm truck during the moving section. |

| Horizontal or Vertical During Traverse | The product release after each posture is carried out at product release position. All the cycles can also be shorten by carrying out posture smoothly as traverse moving over and starting to return. |

| Arm descent delay | Used to shorten the extraction time by letting the vertical arm stand by at just top of the mold before mold open, and adjust the extraction stroke to the shortest. |

| Stacking | Used to stack product at an arbitrary position within the region according to the actual requirements. |

Related Products

Application

About Us

|

Your ideal partner for plastic injection molding machine worldwide.

Key words about Ecotrust brand injection molding machine -Supply from China Famous Brand; -Flexible satisfaction with cost performance requirement; -Professional Teamwork in Marketing, Sales & Service; -10Y+ Work Experience and 30+ Exported Countries. |

Packing & Shipping

FAQ

Q1: How long can it be delivered after the order is placed?

If all the ordered goods are in stock, they can be delivered within 5-7 days after the order is placed;

In case of no inventory of the order goods, the goods can be delivered within 20-120 days after the order is placed.

In case of no inventory of the order goods, the goods can be delivered within 20-120 days after the order is placed.

Q2: How can I buy something different from what I see on the website?

Because the manufacturer will change the product packaging, place of origin or some accessories without any prior notice. We can''t make sure that the goods received by our customers are completely consistent with the pictures, places of origin and descriptions of attachments on the website. We can only make sure that it is genuine! And ensure the same mainstream products with same parameters in the market at that time.

Q3: What should I do if I find quality problems in the process of using my product?

If you need to replace the parts, we will provide them to you in the first time through international express. You will get new parts in 3-5 days.

Q4: Can I choose to buy equipment through Made-In-China company?

We have a professional international trade team, can provide you with SGS, shipping, customs clearance services, please feel free to buy.

Q5: Does the machine have an English manual and warranty card?

Each machine has a professional English operation manual and warranty card.

In addition, we can provide electronic version of the English manual.

In addition, we can provide electronic version of the English manual.

Q6: The delivery time of products without stock is too long for 45 days.

First of all, we will speed production to meet your needs.

In addition, we recommend that you have similar equipment in stock to meet your needs as soon as possible.

In addition, we recommend that you have similar equipment in stock to meet your needs as soon as possible.

Q7: What if I choose the wrong machine?

We have pre-sales engineers with rich professional knowledge. According to your products, we provide the most suitable machines and solutions. Before placing an order, we make sure you don''t choose the wrong machine.

Q8: Who is responsible for the installation and debugging of the machine I purchased?

We the seller are fully responsible to send our engineers within two weeks from the date of the containers arrival to the buyers factory to commissioning the machine and training the staff of the buyer, the buyer should be responsible for a round trip economy ticket, a hotel and any other necessary accommodations for the seller''s engineers, and engineer cost USD 100.00 per day.

Q9: Do you have an aftermarket warranty for your products?

Warranty: General one year for whole injection molding machines, two years for tie bar, three years for platens. Six months for screw and barrel with new material.

General one year for other types of whole machines.

All customers that have bought ECOTRUST injection molding machines would be provided with a lifetime repair service of the machines.

General one year for other types of whole machines.

All customers that have bought ECOTRUST injection molding machines would be provided with a lifetime repair service of the machines.

Hot Searches