- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

Refer to the detail

-

Place of Origin:

-

Jeollabuk-do, South Korea

-

Brand Name:

-

JS CHEM

-

Model Number:

-

Seretite

-

Product Name:

-

Seretite

-

Feature:

-

3 component water based expoxy cement coating

-

Recommended Use:

-

water tank coating floor coating

-

Theoratical coverage:

-

2.14kg/m2 (1mm )

-

Mixing Ratio:

-

1: 2.5: 8

-

Packing:

-

A 2kg B 5kg C 16kg

-

Shelf Life:

-

12 months at the normal temperature

-

Painting Tools:

-

Brush, roller, trowel

-

Gloss:

-

Matte Long-term exposure to sunlight discoloration.

Quick Details

-

CAS No.:

-

Other

-

Other Names:

-

Seretite

-

MF:

-

JS CHEM CORPORATION

-

EINECS No.:

-

Refer to the detail

-

Place of Origin:

-

Jeollabuk-do, South Korea

-

Brand Name:

-

JS CHEM

-

Model Number:

-

Seretite

-

Product Name:

-

Seretite

-

Feature:

-

3 component water based expoxy cement coating

-

Recommended Use:

-

water tank coating floor coating

-

Theoratical coverage:

-

2.14kg/m2 (1mm )

-

Mixing Ratio:

-

1: 2.5: 8

-

Packing:

-

A 2kg B 5kg C 16kg

-

Shelf Life:

-

12 months at the normal temperature

-

Painting Tools:

-

Brush, roller, trowel

-

Gloss:

-

Matte Long-term exposure to sunlight discoloration.

Product Description

Specification

|

Category

|

Description

|

|

Product Name

|

Seretite

|

|

Product Description

|

SERETITE is a It is a water-based epoxy cement based paint which is a mixture of three parts type of base, hardener and powder.

|

|

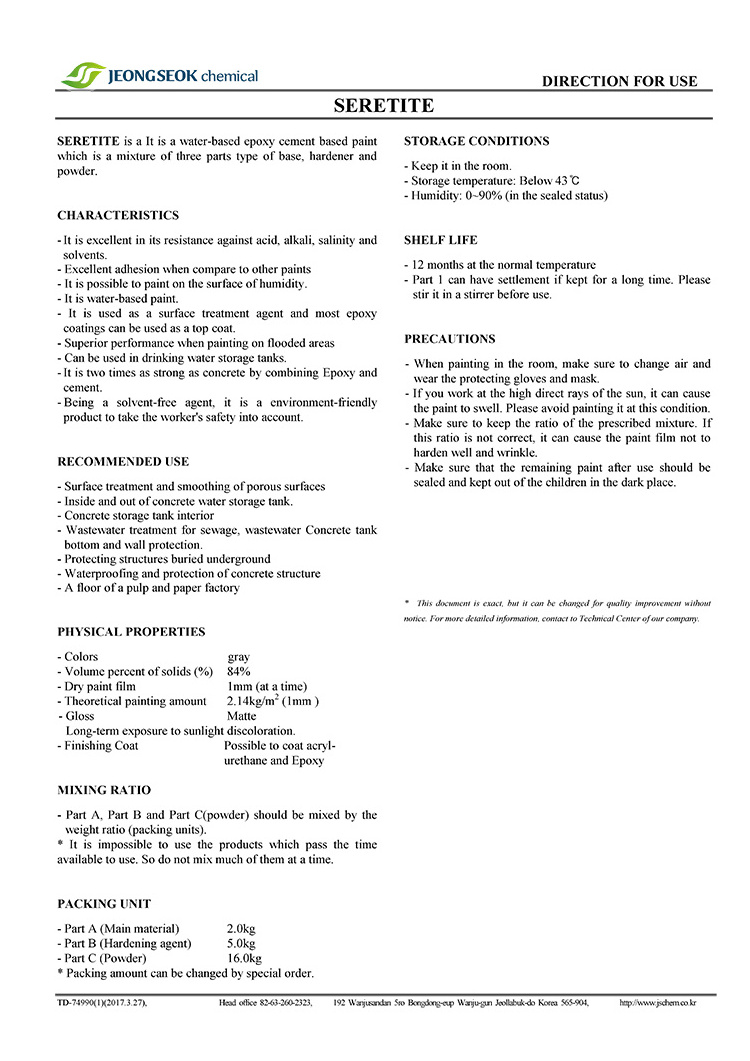

CHARACTERISTICS

|

- It is excellent in its resistance against acid, alkali, salinity and solvents. - Excellent adhesion when compare to other paints

- It is possible to paint on the surface of humidity.

- It is water-based paint.

- It is used as a surface treatment agent and most epoxy coatings can be used as a top coat.

- Superior performance when painting on flooded areas

- Can be used in drinkingwater storage tanks.

- It is two times as strong as concrete by combining Epoxy and cement. - -Being a solvent-free agent, it is an environment-friendly product to take the worker's safety into account.

|

|

RECOMMENDED USE

|

- Surface treatment and smoothing of porous surfaces

- Inside and out of concrete water storage tank.

- Concrete storage tank interior

- Wastewater treatment for sewage, wastewater Concrete tank bottom and wall protection.

- Protecting structures buried underground

- Waterproofing and protection of concrete structure

- A floor of a pulp and paper factory

|

|

Physical properties

|

- Colors gray

- Volume percent of solids (%) 84%

- Dry paint film 1mm (at a time)

- Theoretical painting amount 2.14kg/m2 (1mm )

-Gloss Matte Long-term exposure to sunlight discoloration.

- Finishing Coat Possible to coat acryl- urethane and Epoxy

|

|

Mixing Ratio

|

- Part A, Part B and Part C(powder) should be mixed by the weight ratio (packing units).

1:2.5:8

* It is impossible to use the products

which pass the time available to use. So do not mix much of them at a time. |

|

PACKING

|

- Part A (Main material) 2.0kg

- Part B (Hardening agent) 5.0kg

- Part C (Powder) 16.0kg

* Packing amount can be changed by special order.

|

|

STORAGE CONDITIONS

|

- Keep it in the room.

- Storage temperature: Below 43℃

- Humidity: 0~90% (in the sealed status)

|

|

SHELF LIFE

|

- 12 months at the normal temperature

- Part 1 can have settlement if kept for a long time. Please stir it in a stirrer before use.

|

|

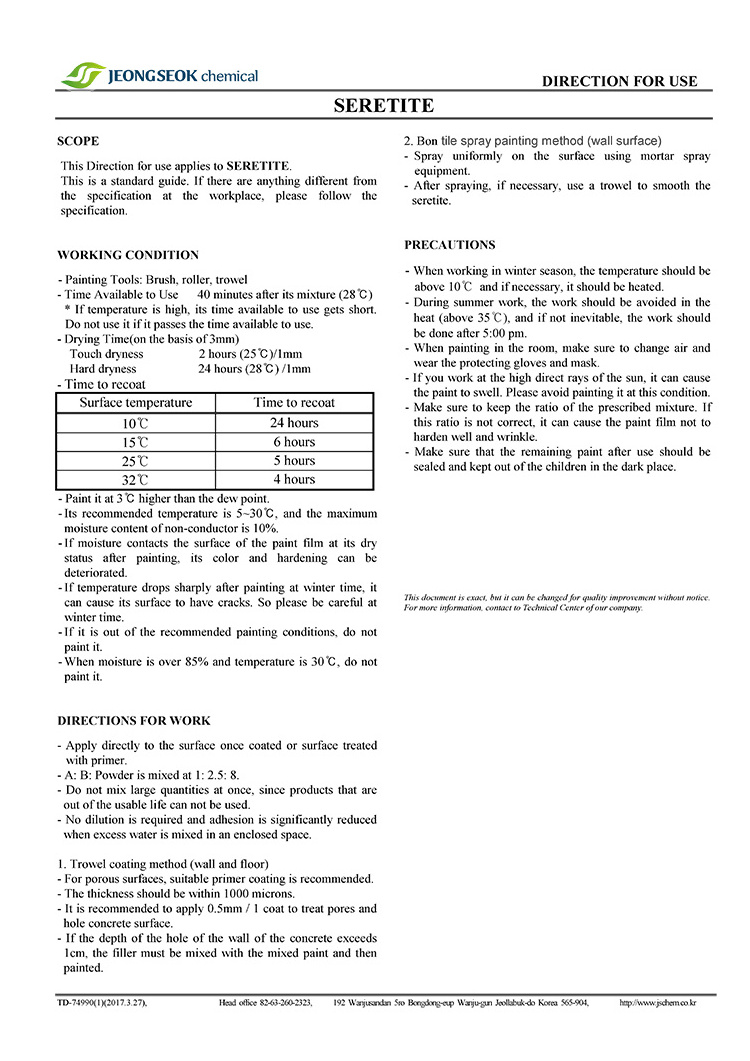

Working Condition

|

- Painting Tools: Brush, roller, trowel

- Time Available to Use 40 minutes after its mixture (28℃)

* If temperature is high, its time available to use gets short. Do not use it if it passes the time available to use.

- Drying Time(on the basis of 3mm) Touch dryness 2 hours (25℃)/1mm Hard dryness 24 hours (28℃) /1mm

- Time to recoat Surface temperature Time to recoat 10℃ 24 hours 15℃ 6

hours 25℃ 5 hours 32℃ 4 hours

- Paint it at 3℃ higher than the dew point.

- Its recommended temperature is 5~30℃, and the maximum moisture content of non-conductor is 10%.

- If moisture contacts the surface of the paint film at its dry status after painting, its color and hardening can be deteriorated.

- If temperature drops sharply after painting at winter time, it can cause its

surface to have cracks. So please be careful at winter time.

- If it is out of the recommended painting conditions, do not paint it.

- When moisture is over 85% and temperature is 30℃, do not paint it.

|

|

DIRECTIONS FOR WORK

|

- Apply directly to the surface once coated or surface treated with primer. - A: B: Powder is mixed at 1: 2.5: 8.

- Do not mix large quantities at once, since products that are out of the usable life can not be used.

- No dilution is required and adhesion is significantly reduced when excess water is mixed in an enclosed space.

|

|

Application Method

|

1. Trowel coating method (wall and floor)

- For porous surfaces, suitable primer coating is recommended.

- The thickness should be within 1000 microns.

- It is recommended to apply 0.5mm / 1 coat to treat pores and hole concrete surface.

- If the depth of the hole of the wall of the concrete exceeds 1cm, the filler must be mixed with the mixed paint and then painted.

2. Bon tile spray painting method (wall surface)

- Spray uniformly on the surface using mortar spray equipment.

- After spraying,if necessary, use a trowel to smooth the seretite.

|

Hot Searches