Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

purelong

-

Model Number:

-

DH-pu301

-

Type:

-

PU

-

Material:

-

Polyuerthane

-

Appearance:

-

Viscous Liquid

-

Application:

-

filtration

-

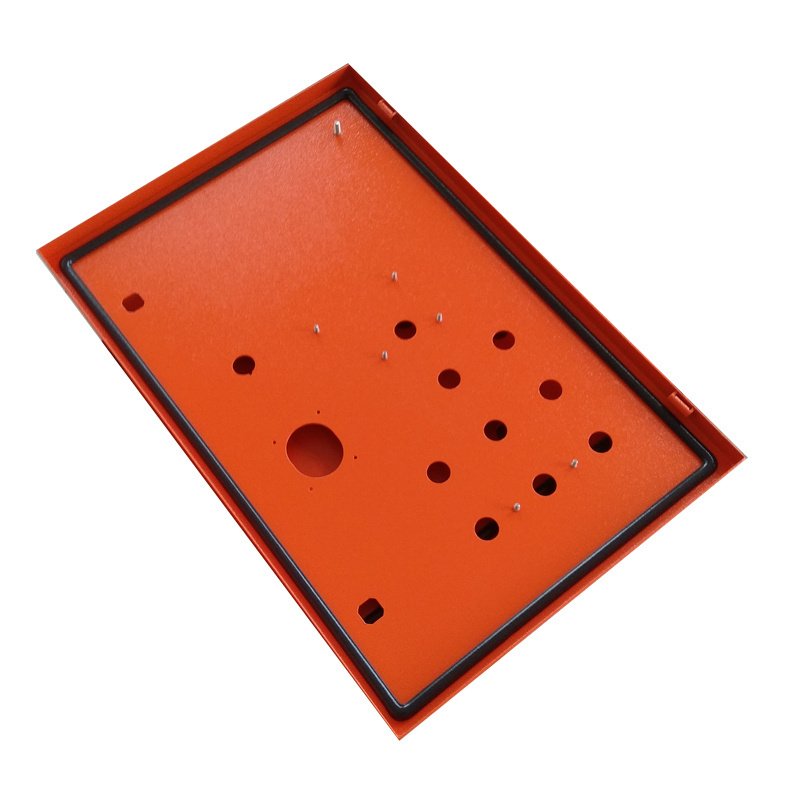

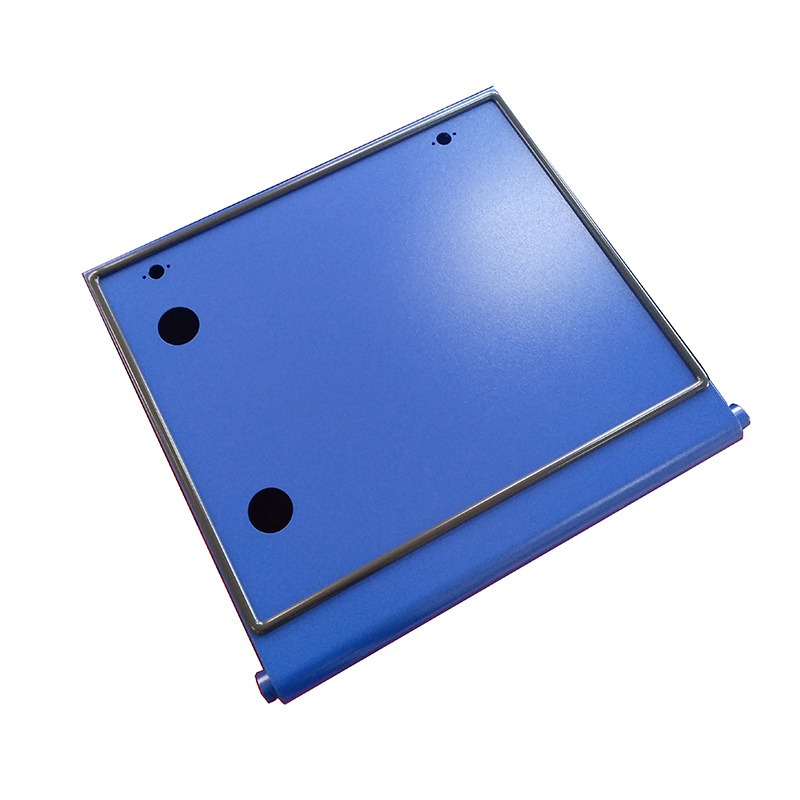

Color:

-

orange and black

-

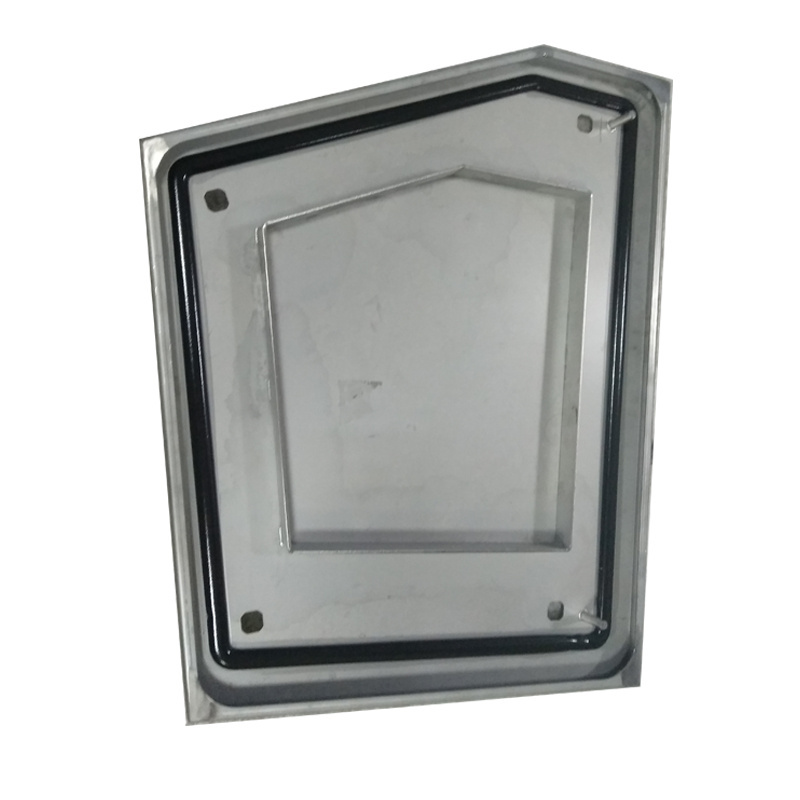

Applied products:

-

air filter

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

filter PU glue

-

MF:

-

mixed

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

purelong

-

Model Number:

-

DH-pu301

-

Type:

-

PU

-

Material:

-

Polyuerthane

-

Appearance:

-

Viscous Liquid

-

Application:

-

filtration

-

Color:

-

orange and black

-

Applied products:

-

air filter

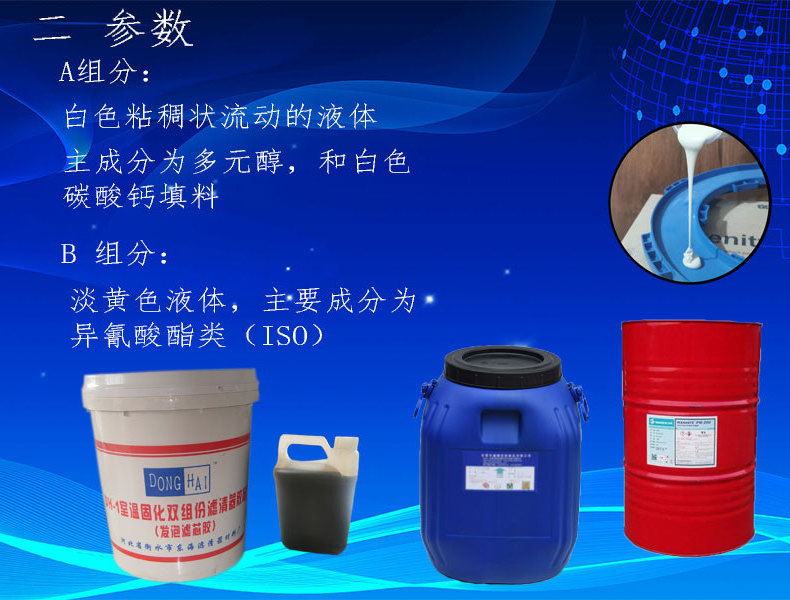

Product Description

|

description

|

Appearance

|

Density(g/cm3)

|

Start foaming time(h)

|

initial curing time(h)

|

|

part A

|

red ,orange, black or According to your requirements

|

1.1+ -0.5

|

|

|

|

part B

|

little yellow liquid

|

1.1+ -0.05

|

|

|

|

A misture B

|

|

|

10-15s

|

10-20min

|

PU glue for Filters - handmade pu glue

PU is the abbreviation of polyurethane can be representative of the polyurethane industryproducts.

Filter industry is often said that PU glue refers PU Elastomer (microporous polyurethane elastomer).

The PU glue for filters is an elastomer with a soft feel, high resilience foam elastic, high tear strength,and which composed of a

polyol and an isocyanate segment.

According to different production operation process the Pu glue can be divided into hand-casting, and machine casting.

Hand pouring PU glue characteristics:

1, due to the relatively slow speed manual dispensing, PU glue with white long period,initiated slowly.

2, A / B component lower viscosity.

3, you can add a lot of calciun carbonate.

4,Easily Handle.

Physical and chemical property and performance:

A material:

Appearance: uniform color of the liquid (the color According to your requirements)

Density: 1.02g/ml

Viscosity :800-1000MPa. S (25 ℃)

B material:

Appearance: brown yellow liquid

Density: 1.02g/ml

Viscosity :25-50MPa. S (25 ℃)

How to use:

1 A material with plastic stir by hand drill, B material Shake,befor use

2, open the hot plate temperature to 40-50 degrees, and hot the A, B material to 25℃

3, wipe with a mold release agent.

4, A, B material according to the ratio of 100:33 ratio, then add 10-40% of talc, with more than 2000 rev / min motor mixing glue,

mixing time determined by the amount of glue, glueabout every 100 grams 3-7 seconds.

5 Stir the liquid mixture into the mold, then put the paper core pressure.

6,10 minutes after stripping.

Storage and packaging:

1, A material storage period of three months. B material storage for 6 months.

2 to above 15 ℃ indoor storage is appropriate.

3, plastic barrels or CTT packaging.

Note:

1, the products are generally stored in a dry room and pay attention to water, moistureand sun. Must cover the inner plug and

outer cover, avoid plastic

PU is the abbreviation of polyurethane can be representative of the polyurethane industryproducts.

Filter industry is often said that PU glue refers PU Elastomer (microporous polyurethane elastomer).

The PU glue for filters is an elastomer with a soft feel, high resilience foam elastic, high tear strength,and which composed of a

polyol and an isocyanate segment.

According to different production operation process the Pu glue can be divided into hand-casting, and machine casting.

Hand pouring PU glue characteristics:

1, due to the relatively slow speed manual dispensing, PU glue with white long period,initiated slowly.

2, A / B component lower viscosity.

3, you can add a lot of calciun carbonate.

4,Easily Handle.

Physical and chemical property and performance:

A material:

Appearance: uniform color of the liquid (the color According to your requirements)

Density: 1.02g/ml

Viscosity :800-1000MPa. S (25 ℃)

B material:

Appearance: brown yellow liquid

Density: 1.02g/ml

Viscosity :25-50MPa. S (25 ℃)

How to use:

1 A material with plastic stir by hand drill, B material Shake,befor use

2, open the hot plate temperature to 40-50 degrees, and hot the A, B material to 25℃

3, wipe with a mold release agent.

4, A, B material according to the ratio of 100:33 ratio, then add 10-40% of talc, with more than 2000 rev / min motor mixing glue,

mixing time determined by the amount of glue, glueabout every 100 grams 3-7 seconds.

5 Stir the liquid mixture into the mold, then put the paper core pressure.

6,10 minutes after stripping.

Storage and packaging:

1, A material storage period of three months. B material storage for 6 months.

2 to above 15 ℃ indoor storage is appropriate.

3, plastic barrels or CTT packaging.

Note:

1, the products are generally stored in a dry room and pay attention to water, moistureand sun. Must cover the inner plug and

outer cover, avoid plastic

Specification

Packing & Delivery

Hot Searches