- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CY

-

Model Number:

-

60BYG250-65

-

Current / Phase:

-

5.8 A

-

Name:

-

nema 24 closed loop stepper motor

-

Diameter:

-

57mm

-

length:

-

65 mm

-

leadwire:

-

4

-

Voltage:

-

3.1 V

-

resistance:

-

0.53

-

inductance:

-

1.2 mH

-

weight:

-

1kg

-

shape:

-

square

-

Key words:

-

Nema 24 Stepper Motor

Quick Details

-

Phase:

-

2

-

Type:

-

Hybrid

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CY

-

Model Number:

-

60BYG250-65

-

Current / Phase:

-

5.8 A

-

Name:

-

nema 24 closed loop stepper motor

-

Diameter:

-

57mm

-

length:

-

65 mm

-

leadwire:

-

4

-

Voltage:

-

3.1 V

-

resistance:

-

0.53

-

inductance:

-

1.2 mH

-

weight:

-

1kg

-

shape:

-

square

-

Key words:

-

Nema 24 Stepper Motor

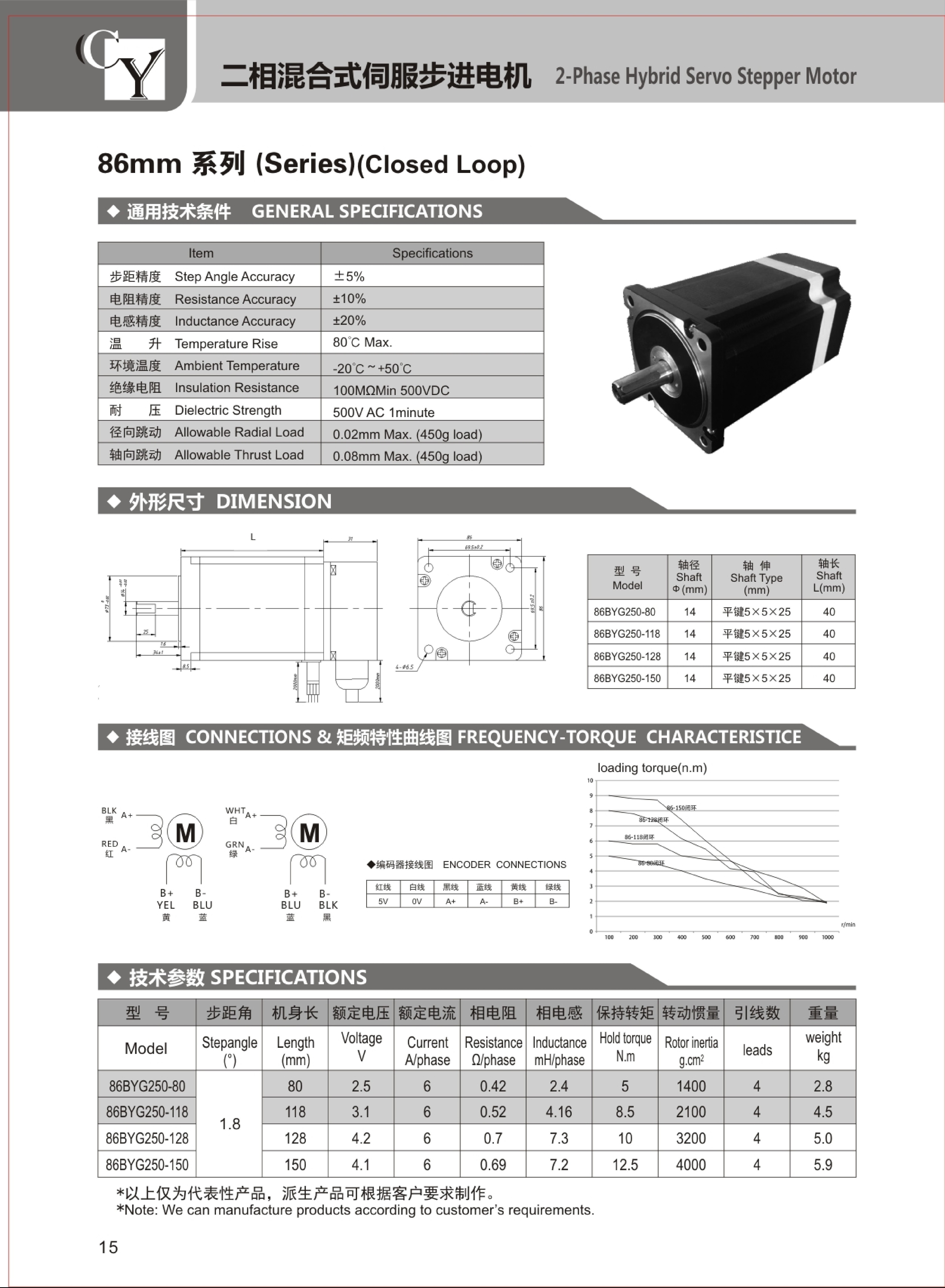

Product Description

Our closed loop stepper motors with a wide range, good quality, reasonable prices and stylish designs, our closed loop stepper motors are extensively used in automation equipment and other industries.

Our closed loop stepper motors are widely recognized and trusted by users and can meet continuously changing economic and social needs.

|

Item

|

Specifications

|

|

Step Angle

|

1.8°

|

|

Step Angle Accuracy

|

±5% (full step, no load)

|

|

Resistance Accuracy

|

±10%(20℃)

|

|

Inductance Accuracy

|

±20%(1KHz)

|

|

Temperature Rise

|

80 ℃Max.(rated current,2 phase on)

|

|

Ambient Temperature

|

-20℃~+50℃

|

|

Insulation Resistance

|

100MΩMin. ,500VDC

|

|

Dielectric Strength

|

500VAC for one minute

|

|

Shaft Radial Play

|

0.02Max. (450 g-load)

|

|

Shaft Axial Play

|

0.08Max. (450 g-load)

|

|

Max. radial force

|

75N (20mm from the flange)

|

|

Max. axial force

|

15N

|

|

Rotation

|

CW( See from Front Flange)

|

|

Leads

|

4

|

|

Model No.

|

Stepangl

°

|

VoltageV

|

Current

A/Phase

|

Resistance

Ω/Phase

|

Inductance

mH/Phase

|

Hold Torque N.m

|

Rotor Inertia g-cm2

|

Weightkg

|

Length mm

|

|

86BYG250-80

|

1.8

|

2.5

|

6

|

0.42

|

2.4

|

5

|

1400

|

2.8

|

80

|

|

86BYG250-118

|

|

3.1

|

6

|

0.52

|

4.16

|

8.5

|

2100

|

4.5

|

118

|

|

86BYG250-128

|

|

4.2

|

6

|

0.7

|

7.3

|

10

|

3200

|

5.0

|

128

|

|

86BYG250-150

|

|

4.1

|

6

|

0.69

|

7.2

|

12.5

|

4000

|

5.9

|

150

|

Product Feature

01. Our company has 20 years of experience in motor production and has fully equipped testing facilities to ensure production quality.

02.The inner rotor adopts German technology, and the surface is coated with imported rotor glue to prevent burrs on the surface after carbon steel oxidation and grinding, which makes the motor noisy.

03.The whole body is made of high-strength metal, which is strong and durable. The side wall has a matte metal texture to increase friction.

04.THigh-quality raw materials and high-specification permanent magnet silicon steel have high positioning accuracy, output torque and fast response speed.

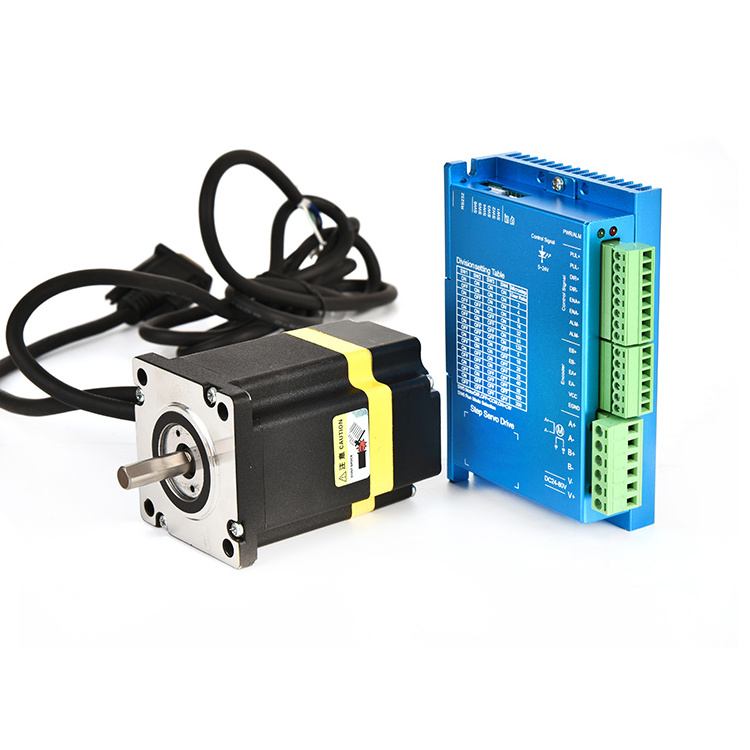

Product Display

Application: Our products are widely used in many machines such as sewing machine,

3D printing machine,vertical packing machine,CNC Lathe Machine,embroidering machine and so on.

Related Products

Production Process

About Us

Changzhou Chuangyi Motor&Electric Applicance Co.,Ltd. It is located in Hutang Town, Changzhou City, Jiangsu Province, which specializes in the hybrid stepping motor. Our company was founded in 2002. Our campany carries forward the business philosophy”Customer First, Keeping on Progress”. And we stick to the principle of “Customer First” tio provide good quality service to our customers.

Product packaging

FAQ

1.Q:Are you factory?

A:Yes, we are facotry, and we produce stepper motor for more then 20 years in China.

2.Q: How to select the motor model?

A: Before purchasing,please contact us to confirm the model no and specification to

avoid any misunderstanding.

3.Q: What’s your warranty?

A:Our warranty is 12 months from shipment out of factory.

4.Q:What is your payment way?

A: Sample fee should be fully paid before production,for bulk order,50% advance is

needed and balance after copy of B/L..

5.Q:How can we know the product quality?

A: We suggest you to order a sample. Also, you can send us email for detail photos for

checking if you cannot get enough information in the product page.

Hot Searches