- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Roson Hardware

-

Product name:

-

Snus cans aluminum

-

Material:

-

Aluminum Alloy

-

Size:

-

7.2*2cm

-

Surface treatment:

-

Sandblasting

-

Process:

-

Cnc Machining + Surface Treatment

-

Service:

-

Customized OEM

-

Equipment:

-

CNC Machining Centres

-

Application:

-

Used Widely

-

OEM/ODM:

-

Accecpted

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Shenzhen

-

Brand Name:

-

Roson Hardware

-

Product name:

-

Snus cans aluminum

-

Material:

-

Aluminum Alloy

-

Size:

-

7.2*2cm

-

Surface treatment:

-

Sandblasting

-

Process:

-

Cnc Machining + Surface Treatment

-

Service:

-

Customized OEM

-

Equipment:

-

CNC Machining Centres

-

Application:

-

Used Widely

-

OEM/ODM:

-

Accecpted

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

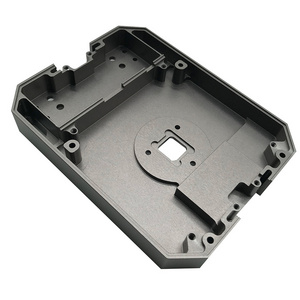

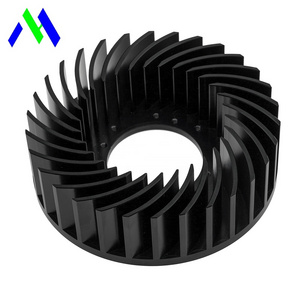

Waterproof Matte Black Color Customized Sand Blast And Anodized CNC Turning Metal Can Aluminum Alloy Parts

|

Product Name

|

Waterproof Matte Black Color Customized Sand Blast And Anodized CNC Turning Metal Can Aluminum Alloy Parts

|

|

Materials

|

Metal: Titanium, Aluminum, Stainless steel & Steel, Brass

|

|

|

Plastic: POM, PEEK, ABS, Nylon, PVC, Acrylic, etc.

|

|

Processing

|

CNC turning, CNC milling, CNC turn-milled, Laser cutting

|

|

Surface Treatment

|

Powder Coated, (Ordinary & Hard) Anodized, Electropolished & Polished, Plating, Bead blasted, Heat treatment, Passivate, Black

oxidate, Brushing, Laser engraving |

|

Tolerance

|

±0.01mm

|

|

Lead Time

|

1-2 weeks for samples, 3-4 weeks for mass production

|

|

Quality Assurance

|

1. 24-hour online service & quick quote/delivery.2. 100% QC quality inspection before delivery, and can provide quality inspection

form.

3. 15+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions.

|

|

Drawing Accepted

|

Solid Works, Pro/Engineer, Auto CAD(DXF, DWG), PDF

|

|

Payment Terms

|

Trade Assurance, T/T, PayPal, West Union

|

Custom Drawing

FAQ

FAQ

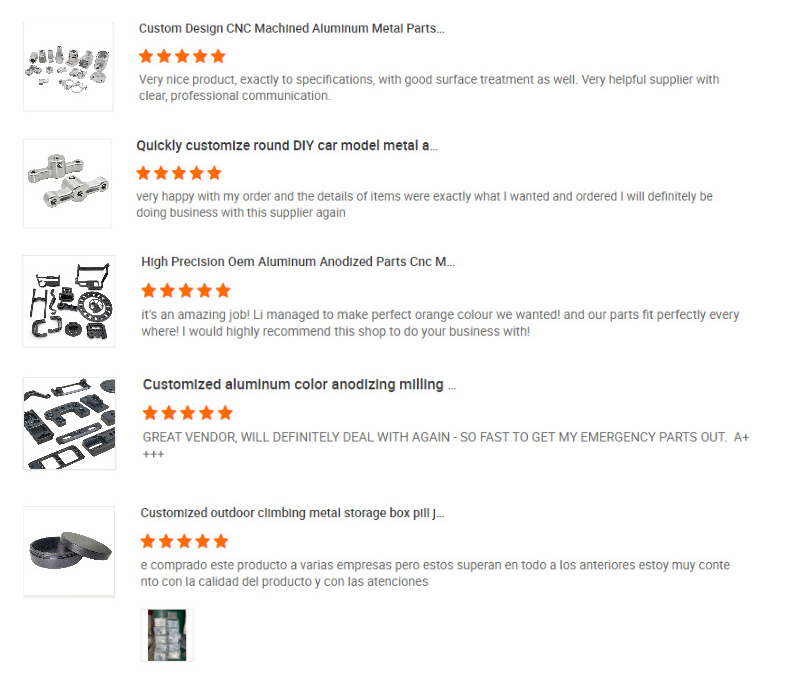

1. Are you a factory or a trading company?

Re: We are an integrated industrial and trade company in Shenzhen Guangdong Province, with a factory of 3,000 square meters.

2. How can I get a quotation?

Re: We will give you a quotation after you have given us detailed drawings (PDF/STEP/IGS/DWG...), including material, quantity and surface treatment information.

3. Can I get a quotation without drawings?

Re: Of course, we appreciate receiving your samples, photographs or drafts with detailed dimensions for a precise quotation.

4. Will my drawings be published if you benefit?

Re: No, we pay a lot of attention to protecting the privacy of our customers' drawings. If you need to, you can also sign an NDA.

5. How about the lead time?

Re: Normally, 1-2 weeks for samples, 3-4 weeks for mass production.

6. How do you control quality?

Re: Our quality inspection department conducts four inspections of each shipment:

(1) Material inspection checks the surface and approximate size of the material.

(2) Production first inspection to guarantee the key size of mass production.

(3) Sampling inspection check the quality before entering the warehouse.

(4) Pre-shipment inspection 100%inspection of QC assistant before shipment.

2. How can I get a quotation?

Re: We will give you a quotation after you have given us detailed drawings (PDF/STEP/IGS/DWG...), including material, quantity and surface treatment information.

3. Can I get a quotation without drawings?

Re: Of course, we appreciate receiving your samples, photographs or drafts with detailed dimensions for a precise quotation.

4. Will my drawings be published if you benefit?

Re: No, we pay a lot of attention to protecting the privacy of our customers' drawings. If you need to, you can also sign an NDA.

5. How about the lead time?

Re: Normally, 1-2 weeks for samples, 3-4 weeks for mass production.

6. How do you control quality?

Re: Our quality inspection department conducts four inspections of each shipment:

(1) Material inspection checks the surface and approximate size of the material.

(2) Production first inspection to guarantee the key size of mass production.

(3) Sampling inspection check the quality before entering the warehouse.

(4) Pre-shipment inspection 100%inspection of QC assistant before shipment.

Hot Searches