- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

alloy C22 / C-4

-

Surface Finish:

-

BA

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTSCO

-

Model Number:

-

ASTM

-

Application:

-

industry

-

Outer Diameter:

-

40mm

-

Material:

-

Alloy B-3 / UNS N10675

-

Surface finish::

-

Bright Annealed, polished etc.

-

Process Method::

-

Cold Drawn/ Cold Rolled

-

Quality Assurance:

-

ISO & PED & AD2000

-

Inspection:

-

100%

-

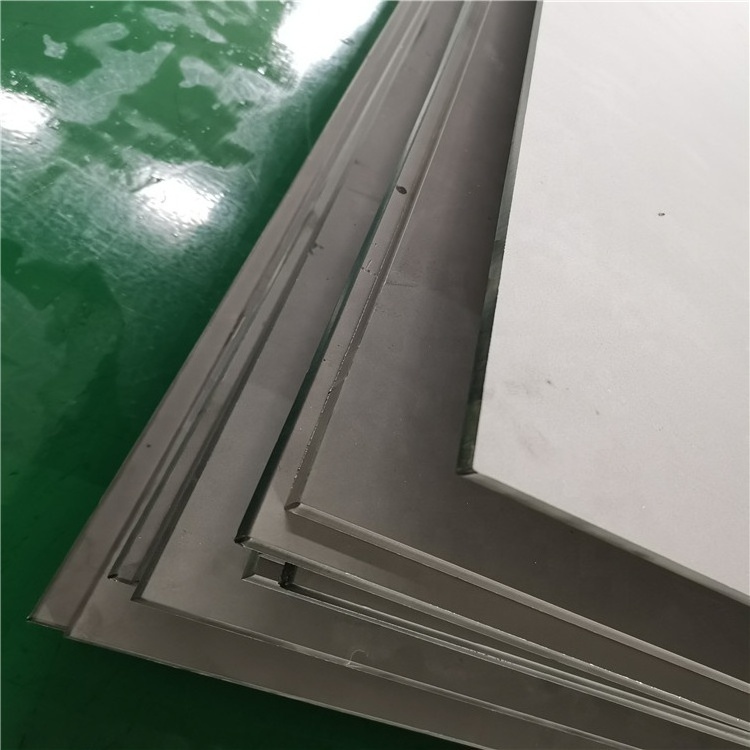

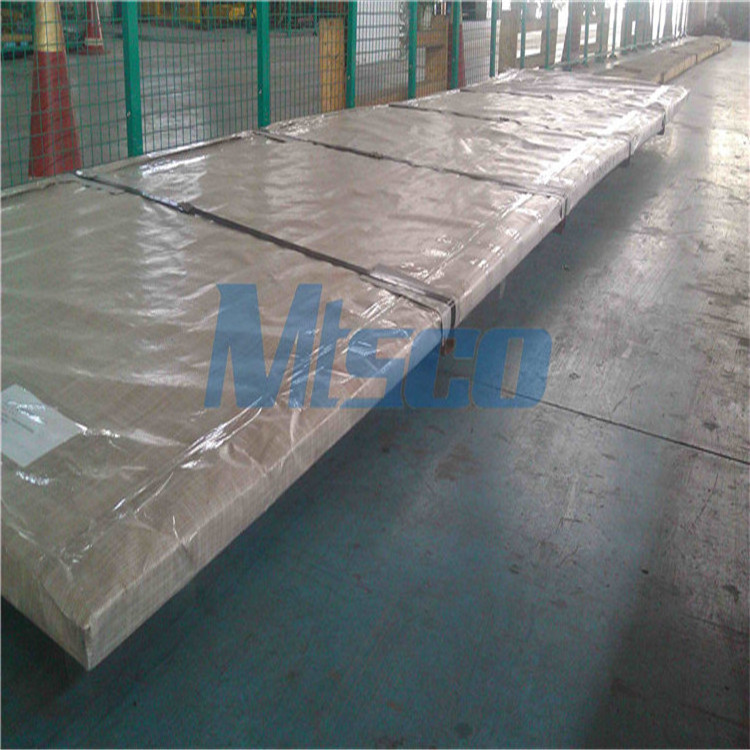

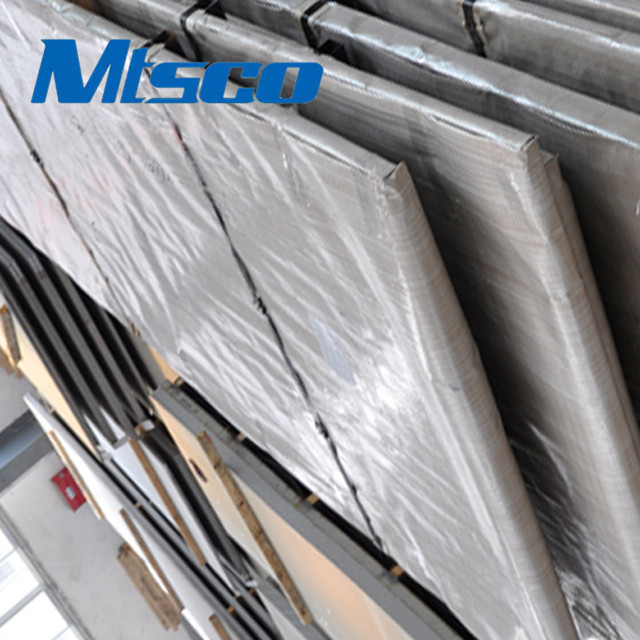

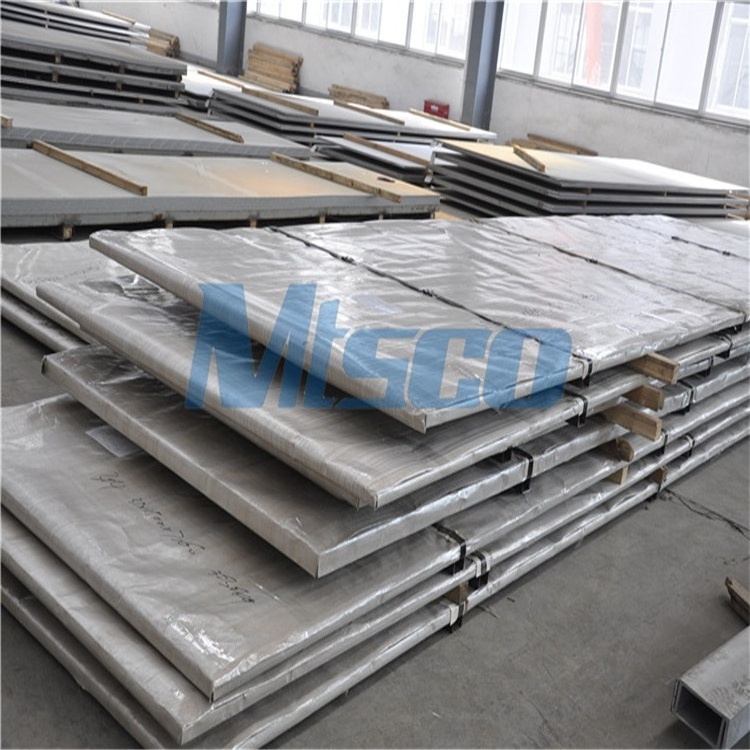

Packing:

-

Plywooden case or Bundle

-

NDT:

-

Eddy Current Or Hydraulic Test

Quick Details

-

Type:

-

Seamless

-

Steel Grade:

-

316L, 316, 304, 304L

-

Tolerance:

-

According customer requirement

-

Grade:

-

alloy C22 / C-4

-

Surface Finish:

-

BA

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTSCO

-

Model Number:

-

ASTM

-

Application:

-

industry

-

Outer Diameter:

-

40mm

-

Material:

-

Alloy B-3 / UNS N10675

-

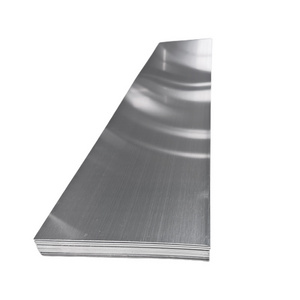

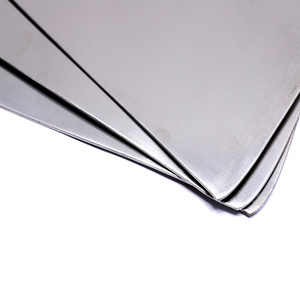

Surface finish::

-

Bright Annealed, polished etc.

-

Process Method::

-

Cold Drawn/ Cold Rolled

-

Quality Assurance:

-

ISO & PED & AD2000

-

Inspection:

-

100%

-

Packing:

-

Plywooden case or Bundle

-

NDT:

-

Eddy Current Or Hydraulic Test

ASTM B575 Alloy C22 / C-4 Nickel Alloy Plate / Sheet,alloy 600 plate

1. Grade : Alloy C276/N10276, A lloy C-4/ UNS N06455, A lloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc

2 . Length : As customer's requirement

3 . Standard : ASTM B333; ASTM B575; ASTM B168; ASTM B443; ASTM B670 etc.

4. Technology : Cold Drawn / Cold Rolled

Alloy C-4 chemical composition:

| % | Ni | Cr | Mo | Fe | Co | C | Mn | Si | P | S | Ti |

| min | balance | 14.0 | 14.0 | ||||||||

| max | 18.0 | 17.0 | 3.0 | 2.0 | 0.015 | 1.00 | 0.08 | 0.040 | 0.030 | 0.70 |

Alloy C22 chemical composition:

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | |||||||

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

Features : Aloy C-4 has outstanding high-temperature stability, and has excellent resistance to stress-corrosion cracking and oxidizing atmospheres up to 1040℃. It has exceptional resistance to a wide variety of chemical process environments, including hot contaminated mineral acids, solvents, chlorine and chlorine contaminated media (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions.

Applications : Chemical processing involving wet chlorine, hypochloric acid, hydrochloric acid, acetic acid and acetic anhydride; flue gas scrubber systems; pickling operations; and electro-galvanizing.