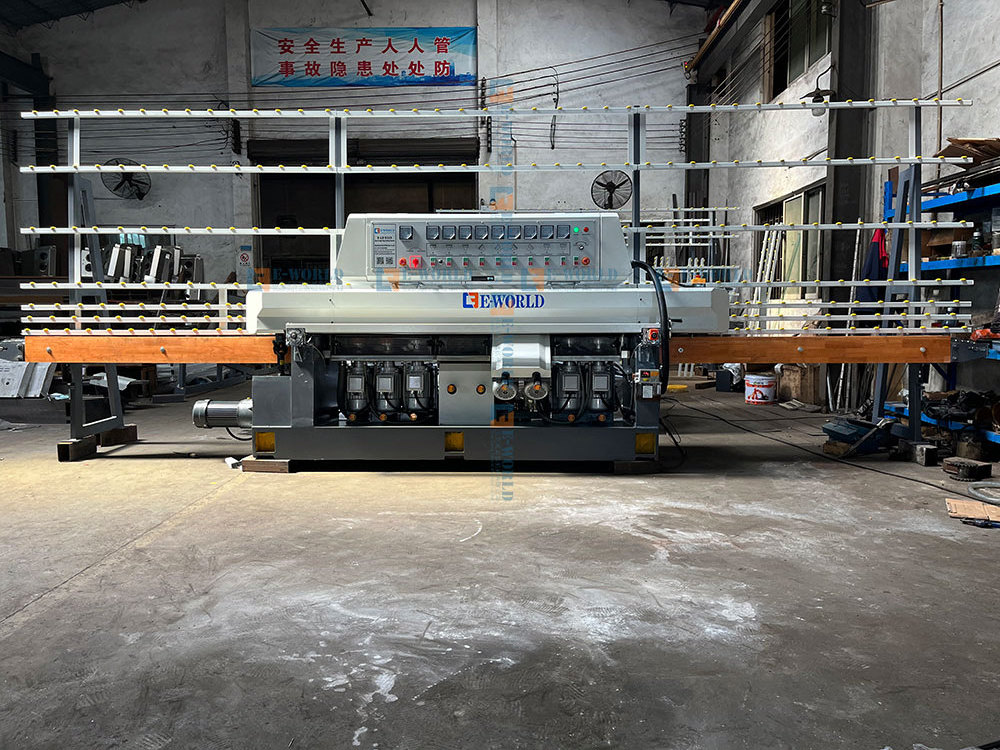

The operation for the

glass machinery to polish edge

is very easy .All the parameters are set by touch screen and PLC control or

the digital meter.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Eworld

-

Voltage:

-

380V

-

Power:

-

19.75kw

-

Dimension(L*W*H):

-

4.2m * 1.2m * 1.9m

-

Weight:

-

2300 kg

-

name:

-

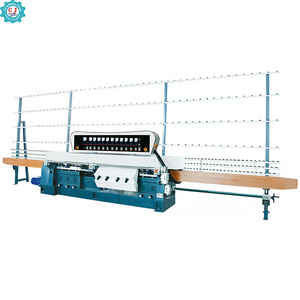

9 spindles Vertical Glass Straight Edge Machine

-

Application:

-

edging glass

-

control:

-

PLC control

-

Color:

-

Customers' Requirement

-

Usage:

-

glass edging machine

-

Package:

-

Plywood Package

-

Function:

-

Vertical glass edging equipment

-

factory sale:

-

Jinan factory sale

-

Working direction:

-

From right to left

-

Wheel type:

-

diamound,resin,polishing wheel

Quick Details

-

Machine Type:

-

Glass Cutting Machine

-

Glass Thickness:

-

3-25mm

-

Production Capacity:

-

0.5-7.0m/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Eworld

-

Voltage:

-

380V

-

Power:

-

19.75kw

-

Dimension(L*W*H):

-

4.2m * 1.2m * 1.9m

-

Weight:

-

2300 kg

-

name:

-

9 spindles Vertical Glass Straight Edge Machine

-

Application:

-

edging glass

-

control:

-

PLC control

-

Color:

-

Customers' Requirement

-

Usage:

-

glass edging machine

-

Package:

-

Plywood Package

-

Function:

-

Vertical glass edging equipment

-

factory sale:

-

Jinan factory sale

-

Working direction:

-

From right to left

-

Wheel type:

-

diamound,resin,polishing wheel

9 motors glass edging machine glass straight line edging machine/CNC glass straight line double edger

Product Description

Product Description

1. ISO standard.

2.

9 spindles

.

3. PLC control

4. Excellent

grinding and polishing

effect.

5. Easy to operate and maintain

6. E-LD9325

Glass Straight line Edging Machine

, is suitable for processing

straight-line edging of glasses

.

7. Sturdy structure enables 24 hours running without stop.

8. Hundreds of edging machines have been made and our experience on edging would be shared with you without any reservation.

Specification

|

9 motors glass edging and polishing machine

|

|

|

|

Quantity of motors:

|

9 sets

|

|

|

Feeding speed:

|

0.5-7m/min

|

|

|

Minimum grinding size:

|

60mm * 60mm

|

|

|

Thickness of the processed glass:

|

3mm-25mm

|

|

|

Power:

|

19.75 kw

|

|

|

Voltage (can be customized-made):

|

380V/50Hz or customized

|

|

|

Exteanal dimension(L * W * H):

|

7.0m * 1.0m * 2.5m

|

|

|

Packing size:

|

4.2m * 1.2m * 1.9m

|

|

|

Weight:

|

3000kg.

|

|

Functions:

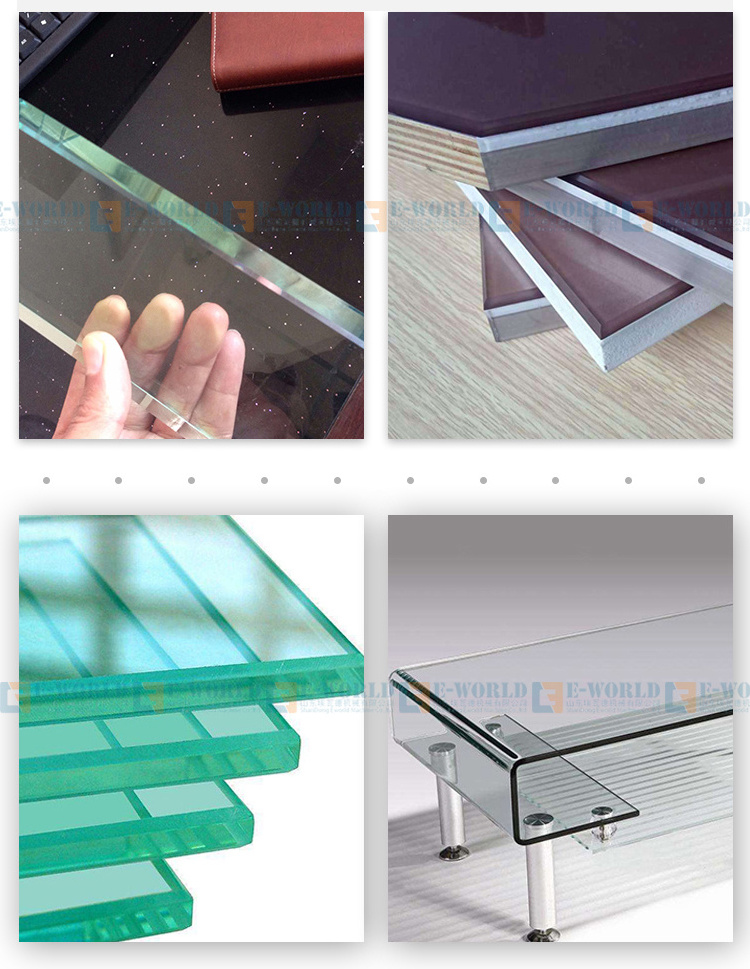

Processes rectilinear glass plates in various sizes and thicknesses;

The

grinding (roughing), finishing

resin and fillets can be performed simultaneously;

The same thickness as the glass sheet can be continuously processed, so that the machine allows having a larger volume of production lines hardening processes, rolling processes and other processing.

Details Images

Brief introduction

1 Complete the coarse

grinding

, accurate

grinding, and polishing of straight-line

hemline and corner angle, at a time with different size and thickness of flat glass.

2 When adjusting the thickness of the different processing, the pre-chamfering grinding head can be moved synchronously as fore beam.

3 Simple to operate and maintain.

4 An ideal for the complete processing of glass.

5 With

9 spindles, PLC controller

if needed.

6 Got CE approval, and are strictly according to the CE standard.

Glass straight edging machine

are use for

straight edging

and

polishing

with different glass size and thickness

The processing speed is adjustable with a step-less motor which offers a wide range of speed selection

Input and output conveyor adopt timing belt which can improve the transmission precision.

Electrical system adopts import components

Polishing

applies pneumatic and manual double system,which has more stable performance. The machine can grind rear conveyor plate by itself to keep high accuracy for long life.

Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge

can be completed in one time.

Same thickness of glass sheet can be process continually. The brightness of finished surface will be almost the same as glass itself.

Packing & Delivery

Our Service

Pre-sale service

Free contact for the most suitable machine

Free professional design for each customer especially.

After sale service

24 hours technical support by phone, email or skype

1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

Payment

T/T, 30% deposit by T/T,70% spare payment before shipment.

Western Union or Paypal.

Western Union or Paypal.

Hot Searches