- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cambery

-

Voltage:

-

380V 60Hz or customized

-

Power:

-

47 kW

-

Dimension(L*W*H):

-

Approx.4760mm*2620mm*2400 mm

-

Weight (KG):

-

5000

-

Overall Size:

-

Approx.4760mm*2620mm*2400 mm

-

Weight:

-

Approx. 5000 kg

-

Power Supply:

-

380V 60Hz or customized

-

Total Power:

-

47 kW

-

Spindle:

-

5.5kW @ 12000r/min 3 kW @ 18000r/min

-

Milling Speed:

-

Up to 10m/min

-

Traveling Speed:

-

X: Up to 40m/min Y: Up to 30m/min Z: Up to 20m/min A: Up to 20m/min

-

Working Size:

-

X: 3310mm Y: 380mm Z: 60mm A: 0-360°

-

Tool Magazine:

-

16 tool slots.

-

Transmission:

-

Helical gear rack

Quick Details

-

Application:

-

woodworking

-

Motor Speed:

-

18000r/min

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cambery

-

Voltage:

-

380V 60Hz or customized

-

Power:

-

47 kW

-

Dimension(L*W*H):

-

Approx.4760mm*2620mm*2400 mm

-

Weight (KG):

-

5000

-

Overall Size:

-

Approx.4760mm*2620mm*2400 mm

-

Weight:

-

Approx. 5000 kg

-

Power Supply:

-

380V 60Hz or customized

-

Total Power:

-

47 kW

-

Spindle:

-

5.5kW @ 12000r/min 3 kW @ 18000r/min

-

Milling Speed:

-

Up to 10m/min

-

Traveling Speed:

-

X: Up to 40m/min Y: Up to 30m/min Z: Up to 20m/min A: Up to 20m/min

-

Working Size:

-

X: 3310mm Y: 380mm Z: 60mm A: 0-360°

-

Tool Magazine:

-

16 tool slots.

-

Transmission:

-

Helical gear rack

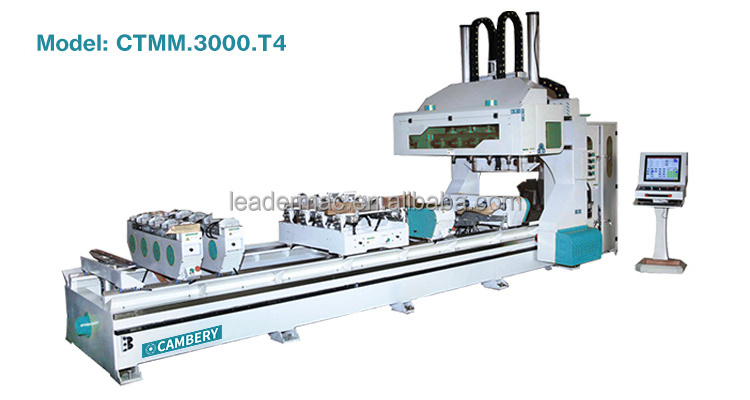

PRODUCT INFORMATION

TECHNICAL CHARACTERISTICS

|

Overall Size

|

Approx.4760mm*2620mm*2400 mm

|

|

Weight

|

Approx. 5000 kg

|

|

Power Supply

|

380V 60Hz or customized

|

|

Total Power

|

47 kW

|

|

Spindle

|

5.5kW @ 12000r/min

3 kW @ 18000r/min |

|

Milling Speed

|

Up to 10m/min

|

|

Traveling Speed

|

X: Up to 40m/min

Y: Up to 30m/min Z: Up to 20m/min A: Up to 20m/min |

|

Working Size

|

X: 3310mm

Y: 380mm Z: 60mm A: 0-360° |

|

Control System

|

HUST® CNC Controller

|

|

Transmission

|

Helical gear rack

|

|

Accuracy

|

Milling: ±0.1mm

Traveling: ±0.03mm |

|

Tool Magazine

|

16 tool slots.

|

|

Regular Clamping

|

Length: 150-3000mm

Thick: Up to 200mm Width: Up to 200mm |

|

Tiger Tenon Clamping

|

Length: 190-1500mm

Thick: Up to 200mm Width: Up to 200mm |

|

Rotation Clamping

|

Length: 160-1000mm

Thick: 25- 200mm Width: 25-150mm |

Applications

DETAILS DISPLAY

STABLE BEDFRAME

● Machine body is manufactured with a rigid foundation, superior welding, CNC machining, tempering and painting to provide a rigid and stable working frame.

CONTROL SYSTEM

● HUST® CNC system, CE certificated.

● General duty program language, easy to use.

● Portable hand wheel for commissioning.

● General duty program language, easy to use.

● Portable hand wheel for commissioning.

QUALITY COMPONENTS

●

Schneider® electronic components.

● AirTac® Pneumatic components.

● AirTac® Pneumatic components.

PRECISE DRIVING SYSTEM

●

Drive by servo motor, combine with liner guide rail, realize accurately feeding positioning, ensure the dimensional accuracy of work-pieces.

●

Auto oiling system, and chip cleansing unit, keep the running smoothly.

POWERFUL MILLING SYSTEM & AUTOMATIC TOOL SYSTEM

●

Equips 5.5KW robust spindle, rotation speed up to 12000rpm.

● Tooling number up to 16pcs, 4 working stations.

● Tooling number up to 16pcs, 4 working stations.

AUTO WASTE DISCHARGE DEVICE

●

Automated waste discharge at a setting time.

CLAMPING SYSTEM

●

Max. up to 4 working pieces in a time.

● Regular clamping system I, workable for milling tenon on two sides and groove on its top surface.

● Tiger tenon clamping system II, workable for turn working pieces in 90 degrees.

● Rotation clamping system III, workable for working pieces rotating.

● Regular clamping system I, workable for milling tenon on two sides and groove on its top surface.

● Tiger tenon clamping system II, workable for turn working pieces in 90 degrees.

● Rotation clamping system III, workable for working pieces rotating.

APPLICATION

Suitable for multi-faceted holes and grooves in one-time process, for all kinds of tenons and grooves: brown corner tenons, sofas, all kinds of tiger corner tenons, straight tenons, waist round tenons, square tenons, angled tenons, shoulder tenons, comb tenons, milling grooves, shaping and other shaped workpieces of high precision processing.

HOT SALE

COMPANY OVERVIEW

WELCOME TO VISIT US

Cooperation with up to 50 countries around the world.

Cooperation with up to 50 countries around the world.

OUR CERTIFICATION

FAQ

Q1. Warranty

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

Hot Searches