- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

50000 KG

-

Machine Type:

-

Automatic Waste Pyrolysis Plant

-

End product:

-

Fuel Oil Steel Carbon Back

-

Reactor thickness:

-

20mm

-

Function:

-

Continuous Pyrolysis Plant

-

Capacity:

-

5-30 TON/DAY

-

Color:

-

Customizable

-

Operating Pressure:

-

Negative Pressure Tyre Pyrolysis Oil

-

Fuel:

-

Coal .wood.gas.electric

-

Raw material:

-

Waste tire/tire powder

-

Application:

-

Tire to Oil pyrolysis machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Equipment Capacity:

-

30TON

-

Weight (KG):

-

50000 KG

-

Machine Type:

-

Automatic Waste Pyrolysis Plant

-

End product:

-

Fuel Oil Steel Carbon Back

-

Reactor thickness:

-

20mm

-

Function:

-

Continuous Pyrolysis Plant

-

Capacity:

-

5-30 TON/DAY

-

Color:

-

Customizable

-

Operating Pressure:

-

Negative Pressure Tyre Pyrolysis Oil

-

Fuel:

-

Coal .wood.gas.electric

-

Raw material:

-

Waste tire/tire powder

-

Application:

-

Tire to Oil pyrolysis machine

Products Description

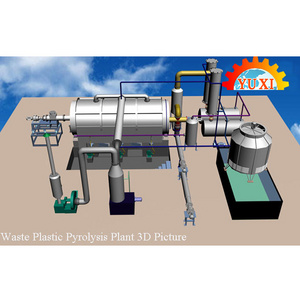

Continuous waste plastic pyrolysis plant ant is equipped with automatic feeding and discharging system, which can realize feeding materials on one side and discharging slag continuously from the other side. Besides, it not only can dispose 30-50 tons waste tyres/plastic per day but also can work continuously for 24 hours without a stop.

|

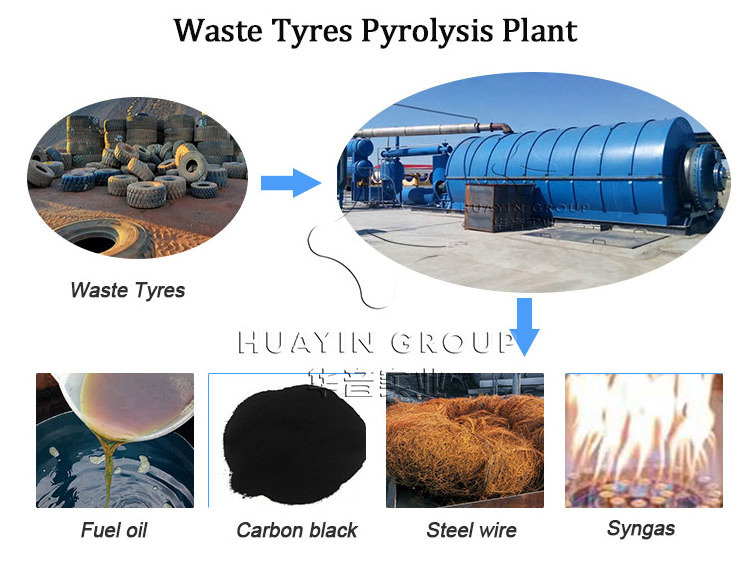

By-Products

|

Application

|

|

Fuel Oil (45%-55%)

|

1. Used as the heating material and sell it to cement factory, glass factory, ceramic factory, electric power factory, steel

making factory, boiler factory, etc. 2. Used in heavy oil generator for electricity generation. 3. Deep process it into diesel oil with our distillation plant, color and smell removal system, the final oil can be used in trucks, tractor, etc. |

|

Carbon Black (30%-35%)

|

1. Make it to pellet or briquette as heating material.

2. Make fine carbon black by carbon black grinding machine. 3. Make carbon to color master batch and sell it to plastic industry. |

|

Steel Wire (10%-15%)

|

1. Sell to iron and steel factory directly.

2. We supply more profitable solution for the steel wire which can be sold about USD460/ton. |

|

Flammable Gas (8%-10%)

|

1. Recycled into furnace to heat reactor instead of coal/wood/oil/natural gas.

2. Storage the exceed gas to restart the next batch. |

Our Advantages

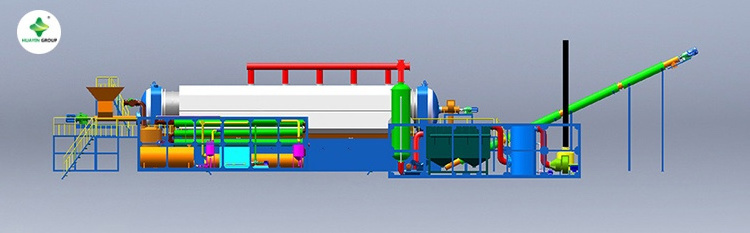

Fully Automated Operation:

From the initial feeding stage to heating, temperature control, cracking, cooling, oil storage, carbon black collection, combustible gas collection for further utilization, and exhaust gas treatment, each process is seamlessly controlled through advanced PLC automation. Real-time monitoring of temperature, pressure, flow rate, and other operational parameters ensures optimal performance. Operators can conveniently manage the equipment's operations from a central control room.

From the initial feeding stage to heating, temperature control, cracking, cooling, oil storage, carbon black collection, combustible gas collection for further utilization, and exhaust gas treatment, each process is seamlessly controlled through advanced PLC automation. Real-time monitoring of temperature, pressure, flow rate, and other operational parameters ensures optimal performance. Operators can conveniently manage the equipment's operations from a central control room.

Safety Assurance:

By implementing full automation, we eliminate the potential risks associated with human error. Our equipment operates with outstanding precision and reliability, ensuring a safe and secure environment for operators and the surrounding areas.

By implementing full automation, we eliminate the potential risks associated with human error. Our equipment operates with outstanding precision and reliability, ensuring a safe and secure environment for operators and the surrounding areas.

Impeccable Cleanliness:

Huayin's latest continuous pyrolysis equipment achieves zero pollution in both exhaust gas emissions and discharging process. This exceptional achievement sets it apart from traditional alternatives.

Huayin's latest continuous pyrolysis equipment achieves zero pollution in both exhaust gas emissions and discharging process. This exceptional achievement sets it apart from traditional alternatives.

Optimal Thermal Utilization:

Our equipment employs a cutting-edge hot air heating system that ensures precise temperature control throughout the pyrolysis process. The reactor's internal uniform temperature distribution reduces temperature differentials. Additionally, the reactor is designed with full coverage, eliminating heat loss from exposed areas. Consequently, our equipment achieves a significantly higher thermal utilization rate than other products in the market, leading to substantial energy savings and lower emissions.

Our equipment employs a cutting-edge hot air heating system that ensures precise temperature control throughout the pyrolysis process. The reactor's internal uniform temperature distribution reduces temperature differentials. Additionally, the reactor is designed with full coverage, eliminating heat loss from exposed areas. Consequently, our equipment achieves a significantly higher thermal utilization rate than other products in the market, leading to substantial energy savings and lower emissions.

Product Paramenters

|

Model

|

HY-05

|

HY-10

|

HY-15

|

HY-30

|

||

|

Capacity

|

5 t/d

|

10 t/d

|

15 t/d

|

30 t/d

|

||

|

Working Type

|

Batch

|

Batch

|

Batch

|

Continuous

|

||

|

Reactor size(m)

|

D2.2*L5.5

|

D2.8*L6.6

|

D2.8*L8.1

|

D1.2*L24

|

||

|

Reactor material

|

Q245R

|

Q245R

|

Q245R

|

310S stainless steel

|

||

|

Power

|

29.4KW

|

32KW

|

34KW

|

100KW

|

||

|

Heating Fuel

|

Pyrolysis oil

|

|

|

|

||

|

Burners

|

3*300,000 kcal

|

3*300,000 kcal

|

4*300,000 kcal

|

12*300,000 kcal

|

||

|

Working pressure

|

Normal

|

Normal

|

Normal

|

Normal

|

||

|

Landing Area

|

200m2

|

35300m2

|

350m2

|

700m2

|

||

|

Number of Containers

|

1*40FR+1*40HQ

|

1*40FR+2*40HQ

|

1*40FR+2*40HQ

|

bulk cargo

|

||

|

Noise (dB)

|

≤60

|

≤60

|

≤60

|

≤60

|

||

|

Cooling Mode

|

Circle Water

|

Circle Water

|

Circle Water

|

Circle Water

|

||

Product Show

Product packaging

Hot Searches