- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ABM

-

Model Number:

-

NdFeB FOR magnetic rotor

-

Magnetic rotor:

-

magnet,shaft plastic overmolded

-

Product Name:

-

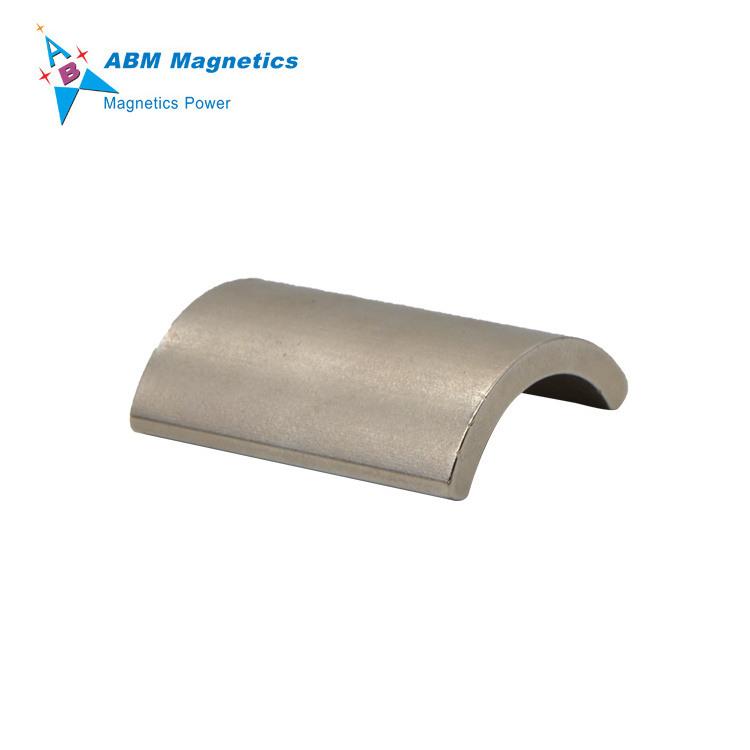

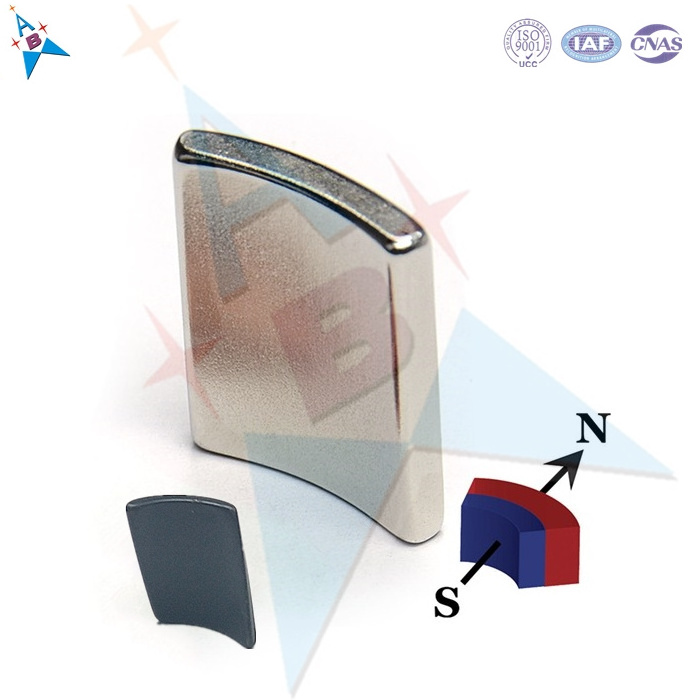

motor magnet

-

Process:

-

low rpm 5kw 220v strong magnet generator/neodymium motor magnet

-

Certificate:

-

TS16949

-

Advantages:

-

good balance, low weight, high rotationa speed, low noice

-

Material:

-

NeFeB magnetic rotor

-

Magnetism direction:

-

Customzied Specific Requirements

Quick Details

-

Tolerance:

-

±5%

-

Grade:

-

neo, N35-N52 (M.H.SH.UH.EH.AH)

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ABM

-

Model Number:

-

NdFeB FOR magnetic rotor

-

Magnetic rotor:

-

magnet,shaft plastic overmolded

-

Product Name:

-

motor magnet

-

Process:

-

low rpm 5kw 220v strong magnet generator/neodymium motor magnet

-

Certificate:

-

TS16949

-

Advantages:

-

good balance, low weight, high rotationa speed, low noice

-

Material:

-

NeFeB magnetic rotor

-

Magnetism direction:

-

Customzied Specific Requirements

ABM low rpm 5kw 220v permanent strong magnet generator/neo magnet motor/neodymium motor magnet

Magnetic Rotor—(NdFeB magnet ,steel shaft, ceramic shaft with plastic overmolded)

Working in combination of plastic over-molding, gluing, clamping, potting and fiber-wrapping, our magnetic rotor has performed the following advantages. Its components included steel or ceramic shaft, steel shaft, steel housing, steel pot, magnet, plastic overmolded and so on.There have many different ways to achieve the same effect, we will carry out the more cost-effective way to optimize the magnetic circuit or geometry. By this way, usually cost savings of magnet or magnetic properties further improved by nearly 20%.

Our Magnetic Rotor Advantages

3: Perfect balance.

4: High stability and consistency in magnetic performance (Magnetic field strength, pole angle......)

5: Perfect mechanical property (No crack happen)

ABM focus on providing best quality magnet to every customer and we also receive lots of 5 stars reviews from customer all over the world.

Our R&D Team Capacity

ABM Magnetics has first-hand unmatched magnetic rotor,magnetic sensor, magnetic components and magnetic assembling design and manufacturing experience,our R&D team can help you to select the most cost-effective magnet material, magnet grade and optimized geometry for your application.

1: Simulation calculation as to magnetic systems

2: Tool construction

3: Measuring of magnetic properties

4: Testing of the magnetic material

5: Customer support from an idea to post-marketing activities

There have a typical design case which ABM R&D team worked together with customer to optimize the for parameters to achieve the optimum design for final application.

—ABM Magnetics can make the magnetizing fixture design, construction and running the magnetizing for magnet with diferent magnetization pattern based on customer's application requirement.

Our Measurement Capability

The magnetic performance (magnetic flux, magnetic field strength, pole angle, magnetic declination and the magnetic property(Br,Hcj,Hcb,BH) of magnetic material are one of primary parameter for a magnetic rotors, so the professional and exact measure will be required during magnet design and manufacturing.

Measuring Tool

1.Gaussmeter,it's for magnetic strength measurement

2.Fluxmeter,it's for magnetic flux measurement

3.Multi-magnetic poles scanner,it's for magnetic strength and pole angle measurement

4.Gaussmeter probes

5.Helmholtz coil

6.Magnetic declination tester

7.Hysteresigraph tester,it's for magnetic material grade measurement(Br,Hcj,Hcb,BH)

It's a typical flux density(Gauss) Vs.distance(air gap) diagram.It's useful when working on magnetic rotor, pump, motor,magnetic sensor, magnetic component designs to understand its application performance.Below show the flux density with different air gap between magnet and hall-probe by scanning, the data can be helpful to work out the optimum distance between magnet and sensor for final application.

—We offer decades of experience and technology leadership along with the industry’s most extensive investment in engineering and tools to help our partners and customers achieve the most demanding application requirements

1: Ensured short time from an idea to the actual product

2: Veriety of magnetic materials

3: Technology of composites

4: Integral solutions

5: Different production locations

6: Vertical integration in the group from raw material to products

7: Wide supplier net for strategic raw materials

8: Developmental partner with most of the customers

9: Production flexibiliyt (small- and large-series production)

—ABM often attended many exhibitions which forcusing on the Motor, Electric Machinery & Magnetic Materials design and manufacturing.

—In the exposition scene, many customers are very interesting in our magnets, especially in our design and manufacturing capability.

— We received a lot of feedback after exhibition, many customer are very impressed with our magnet and magnet, magnetic rotors, magnetic components.