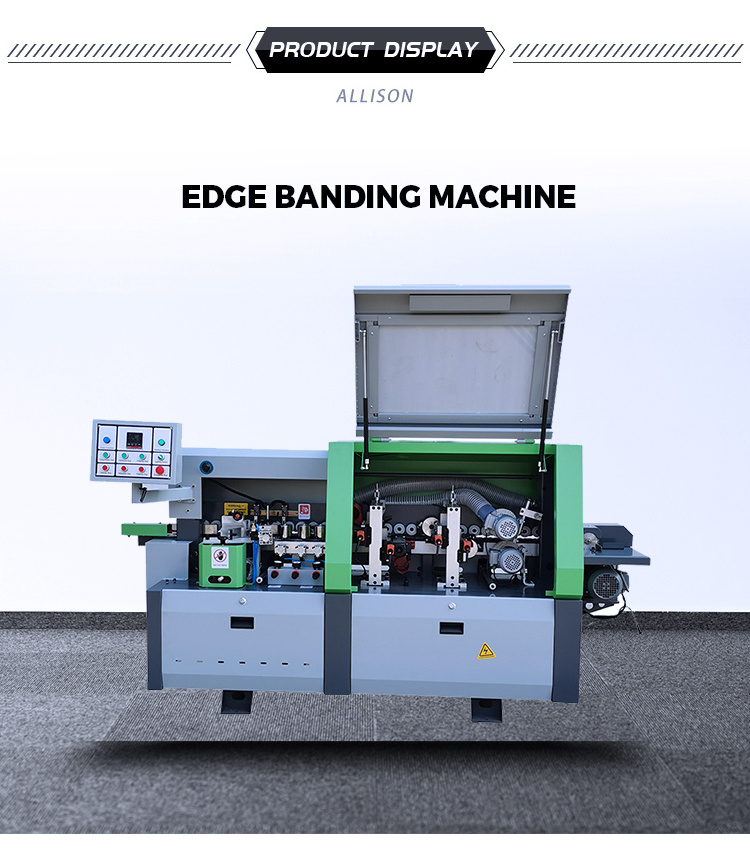

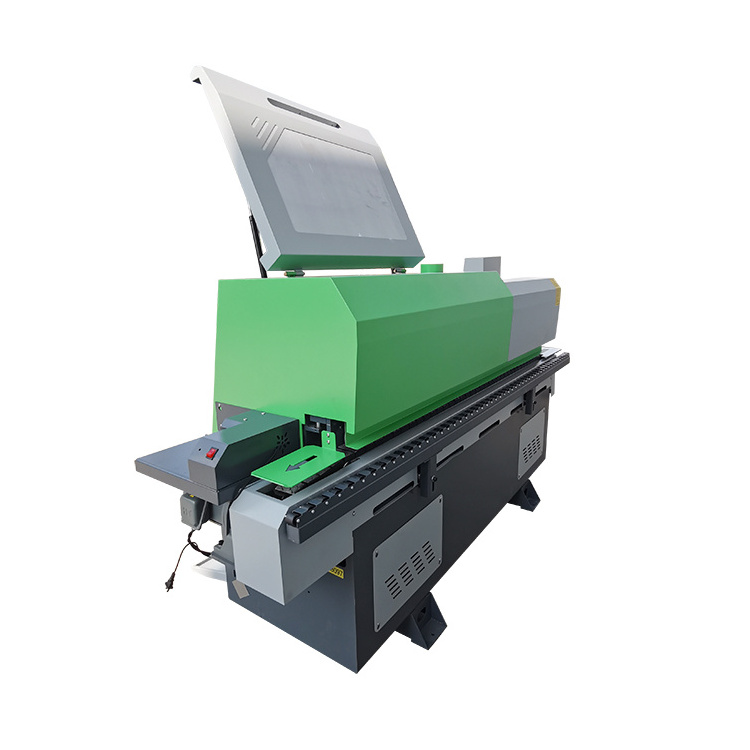

Through the special structure, the double-sided gluing of edge sealing plate and edge sealing material is

uniform to ensure more firm adhesion.

uniform to ensure more firm adhesion.

|

Functions

|

Gluing edge,Snipping, Fine trimming, Scraping ,Buffing,End cutting

|

|

Overall Size

|

3300*750*1500mm

|

|

Total Weight

|

800kg

|

|

Total Power

|

≧50mm

|

|

Min edge band Length

|

≧60mm

|

|

Plate thickness

|

10-60mm

|

|

Edge band width

|

10-65mm

|

|

Edge band thickness

|

0.4-3mm

|

|

Conveyor Speed

|

15m\min

|