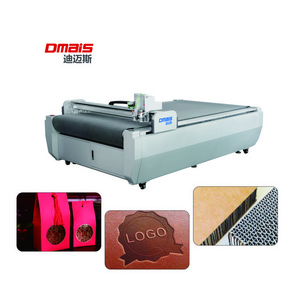

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YINENG TECH

-

Power:

-

16-25kw

-

Dimension(L*W*H):

-

5900*3250*2150mm

-

Weight:

-

4500 KG

-

Software:

-

Automatic Cutting System Copyright

-

Control system:

-

YINENG CUT V4.0

-

Cutting Thickness:

-

7 Cm/11 Cm

-

Cutting Accuracy:

-

<=1mm

-

air pressure supply:

-

7kps

-

Cutting Type:

-

Striaght Knife Continuous Up-down Cutting

-

certification:

-

CE

-

Material Capabilities:

-

Polyester Fabric

-

Cutting materials::

-

garment/cloth/textile/leather

-

Cut speed::

-

0-60000mm/min

Quick Details

-

Production Capacity:

-

10 sets/month

-

Voltage:

-

380V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENG TECH

-

Power:

-

16-25kw

-

Dimension(L*W*H):

-

5900*3250*2150mm

-

Weight:

-

4500 KG

-

Software:

-

Automatic Cutting System Copyright

-

Control system:

-

YINENG CUT V4.0

-

Cutting Thickness:

-

7 Cm/11 Cm

-

Cutting Accuracy:

-

<=1mm

-

air pressure supply:

-

7kps

-

Cutting Type:

-

Striaght Knife Continuous Up-down Cutting

-

certification:

-

CE

-

Material Capabilities:

-

Polyester Fabric

-

Cutting materials::

-

garment/cloth/textile/leather

-

Cut speed::

-

0-60000mm/min

Company information

About us

YINENG TECH was founded in the year of 2002. Our company covers an area of 80000 square meters factory, with 36 sales offices and 64 after-sales service office around the world. As a professional automatic cutting system supplier, we are specialized in research, manufacturing and sales, until now we have provided automatic cutting solutions for over 5,000 customers from more than 20 countries around the world., which all over Asia, Europe , North America, South America, Central America and Africa, covering clothing, furniture, bags, toys, shoes, car seats, aerospace, airships, boats, wind power materials, packaging, and other fields.

Products Description

|

Model.NO

|

KP-X1725

|

KP-X2025

|

KP-X2325

|

KP-X1733

|

KP-X2033

|

KP-X2333

|

|||||

|

Cutting area (W*L)

|

1700x2500mm

|

2000x2500mm

|

2300x2500mm

|

1700x3300mm

|

2000x3300mm

|

2000x3300mm

|

|||||

|

Machine Dimensions (mm)

|

6000*2650*1500

|

6000*2950*1500

|

6000*3250*1500

|

7500*2650*1500

|

7500*2950*1500

|

7500*3250*1500

|

|||||

|

Weight

|

4200kgs

|

4500kgs

|

4800kgs

|

4800kgs

|

5000kgs

|

5500kgs

|

|||||

|

Max cutting speed

|

60m/min

|

|

|

|

|

|

|||||

|

Cutting accuracy

|

≤±1mm

|

|

|

|

|

|

|||||

|

Power

|

16-25kw

|

|

|

|

|

|

|||||

|

Cutting style

|

Straight Knife Continuous Up-down Cutting

|

|

|

|

|

|

|||||

|

Cooling system

|

Auto air cooling system

|

|

|

|

|

|

|||||

|

Controller system

|

KP-ACS Copyright system which compatibility with any kind of cloth CAD software

|

|

|

|

|

|

|||||

|

Software

|

Multi-language ACS software, switch freely

|

|

|

|

|

|

|||||

|

Sharpen way

|

Double gear derogatory method

|

|

|

|

|

|

|||||

|

Air pressure supply

|

0.55Mpa 160L/Min

|

|

|

|

|

|

|||||

|

Cutting materials

|

Garment/Cloth/Textile/Leather

|

|

|

|

|

|

|||||

|

Max speed of blade working

|

4000rpm/min

|

|

|

|

|

|

|||||

|

Motor & driver

|

Japan Panasonic servo motors & drivers

|

|

|

|

|

|

|||||

|

Machine power

|

AC380V/50HZ

|

|

|

|

|

|

|||||

|

Software

|

Auto cutting

|

|

|

|

|

|

|||||

Machine Work Environment

|

1

|

Working Temperature

|

|

0℃-50℃

|

|

||

|

2

|

Relative humidity

|

|

<90%( non-condensing)

|

|

||

|

3

|

Surrounding Environment

|

|

Ventilation, no big impact

|

|

||

|

4

|

power supply

|

|

220V/380V±10%

|

|

||

|

5

|

Frequency

|

|

50Hz

|

|

||

|

6

|

Input power

|

|

<23KW

|

|

||

|

7

|

Grounding type

|

|

Centralized direct grounding

|

|

||

|

8

|

Air pressure supply

|

|

0.55Mpa 160L/min

|

|

||

Machine features

Machine body structures:

1. The machine body is whole body with full welding, and the weight is one time heavier than the auto cutter from other factories, our machine weight is about 4.5 tons.

2.

Machine body is been milled by the Large five-axis milling machine with one time fine milling, which can ensure the table is very flat and smoothly.

3.The machine body adopt the advance steel plate seamless connection of square box with high-speed machine bed structure, with annealing stress-relief which can relieve stresses to make sure the machine body no deformation for at least 10 years.

XY Transmission Way

The XY transmission system adopt the Germany gear and rack, the Mechanical precision error is less than 0.1mm.

Controller System

1. Our software and controller system was been researched by our own technical team, the most

important is that we own the only copy right.So if you need to do any modifications in the software, we can customized for you, for some special industry, like: underwear, we can do the knife modification for the knife edge, like V cut, U cut, I cut.

2.

On the other hand, it can accept 98% of cloth CAD software , and it can automatically identify any different file format like DXF, LEC, TAC, CUT, NC, PLT, this will save a lot of time for the patterning & plate-making master, and make the work connection much more convenient, so it will preciously improve the working efficiency.

3. Our software has a powerful power-off memory function, and the accuracy error is within 1mm.

4. Besides, we can update the software for you every three months and the service is free.

Knife Sharpening System

The equipment adopts automatic knife sharpening technology,the knife sharpening time can be controlled by different fabric, which will extend the using life of the cutting blade.

Safety System

Safety device:Anti-collision device to prevent the machine hit someone who is standing by the machine.

YINENG Factory Production Line

Sample

Packing&Shipping

- Packaging Details: Cutting Machine with water-proof film and standard wooden case

- Port: Shanghai, Shenzhen

- Lead Time : within 25 working daya after deposit

After Sales Service

1.Pre-sales service -- professional individual consultation

A. Free sample making

For free sample making/testing, please send your samples or products CAD Graphics to our company in China. Try before you buy.

B. Progressing solution design

According to customer’s product processing requirement, we can design the unique solution that supports higher

manufacturing efficiency and better processing quality for customer.

2. After-sales service – professional qualification and training

One-year after-sales service includes:

A. We will offer some of the parts for free in the first year. The buyer needs to pay for the shipping cost for the parts. The user needs to send us pictures of the broken one, then we will send out the part they need.

B. In the first year, if the buyer needs our engineers to come to the local to fix some problems of the machine that they cannot fix by themselves; we will send our engineers for free. The buyer needs to pay the flights, housing and meals for the engineers in the local.

C. We will offer our service through email and phones if the buyer needs any help on technical problems.

3. Installation and technical training includes

We will send our engineers to customer’s factory for the local training and the installation, and this is free. The buyer needs to pay hotel and meals for the engineers in the local.

In-time golden services

Responsive within 24 hours technical support provided for peace of mind.

4.Customer-orient maintenance cost control guide

A. Parts supply in time we produce on order, Parts in warehouse for over 30 sets to guarantee the delivery of order and maintenance.

B. Release clients worry about big equipment service; supply the part with bare cost.

5. Sales service management system

Standardized service management system, including: customer contact management, customer troubleshooting management, customer equipment regular maintenance, inspections management, customer records management and other accessories reviews.

Hot Searches