- Product Details

- {{item.text}}

Quick Details

-

Power:

-

55

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

1500 kg

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Power:

-

55

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

1500 kg

-

Certification:

-

CE

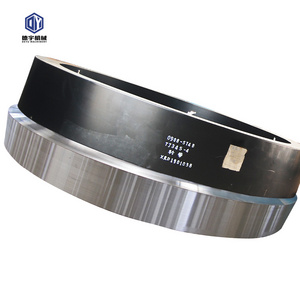

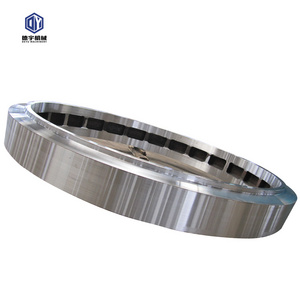

Products Description

Cement kilns

are mainly used for calcination of cement clinker, divided into two categories: dry production cement kilns and wet production cement kilns. Metallurgical chemical kilns are mainly used for the magnetic roasting of lean iron ore in steel plants in the metallurgical industry; oxidation roasting of chromium and nickel iron ore.

Production capacity: 180-10000t/d

Motor power: 55-950×2kw

Total weight: 149.61-1659t

Technical Parameter

|

Model(m)

|

Capacity(t/d)

|

Rotating speed(r/min)

|

Power(kw)

|

Weight(t)

|

|

Φ2.5×40

|

180

|

0.44-2.44

|

55

|

149.61

|

|

Φ2.5×50

|

200

|

0.62-1.86

|

55

|

187.37

|

|

Φ2.5×54

|

280

|

0.48-1.45

|

55

|

196.29

|

|

Φ2.7×42

|

320

|

0.10-1.52

|

55

|

198.5

|

|

Φ2.8×44

|

450

|

0.437-2.18

|

55

|

201.58

|

|

Φ3.0×45

|

500

|

0.5-2.47

|

75

|

201.94

|

|

Φ3.0×48

|

700

|

0.6-3.48

|

100

|

237

|

|

Φ3.0×60

|

800

|

0.3-2

|

100

|

310

|

|

Φ3.2×50

|

1000

|

0.6-3

|

125

|

278

|

|

Φ3.3×52

|

1300

|

0.266-2.66

|

125

|

283

|

|

Φ3.5×54

|

1500

|

0.55-3.4

|

220

|

363

|

|

Φ3.6×70

|

1800

|

0.25-1.25

|

125

|

419

|

|

Φ4.0×56

|

2300

|

0.41-4.07

|

315

|

456

|

|

Φ4.0×60

|

2500

|

0.396-3.96

|

315

|

510

|

|

Φ4.2×60

|

2750

|

0.41-4.07

|

375

|

633

|

|

Φ4.3×60

|

3200

|

0.396-3.96

|

375

|

583

|

|

Φ4.5×66

|

4000

|

0.41-4.1

|

560

|

710.4

|

|

Φ4.7×74

|

4500

|

0.35-4

|

630

|

849

|

|

Φ4.8×74

|

5000

|

0.396-3.96

|

630

|

899

|

|

Φ5.0×74

|

6000

|

0.35-4

|

710

|

944

|

|

Φ5.6×87

|

8000

|

Max4.23

|

800

|

1265

|

|

Φ6.0×95

|

10000

|

Max5

|

950×2

|

1659

|

Application

Handling materials

1. Sludge:

municipal sludge, river sludge, lake bottom sludge, leather sludge, electroplating sludge, pickling sludge, oil well sludge, coal gangue, fly ash, slag, construction spoil, subway spoil , Various contaminated soils, etc.

2. Solid waste:

steel mill flue ash, sugar slag, pharmaceutical factory filter slag, aluminum slag, paint slag, waste tire refining, papermaking slag, glass slag, ceramic slag

3. Peat:

drying of viscous filter cake materials such as coal slime, washed coal, municipal sludge, coal slime, choline chloride, red mud, biological waste residue, etc.

Feature

1. Kaolin rotary kiln has simple external structure and reasonable internal structure, which is easy to install, operate and maintain;

2. The cylinder inside the kiln runs very uniformly, with low heat energy consumption, low power consumption and low failure rate, which not only effectively realizes the recycling of heat energy, but also reduces production costs;

3. The sealing inside the kiln is relatively reasonable, effectively preventing the entry of foreign matter and cold air from the outside, and at the same time reducing the spillage of dust, reducing dust pollution and improving the production environment;

4. The equipment is equipped with an automatic cooling device. The calcined kaolin will automatically enter the cooling device to realize automatic cooling, which can effectively improve the recycling rate of kaolin materials and increase product output.

Packaging and Shipping

Why Choose Us

After years of development, Zhengzou Yuxi Machinery Equipment Co., Ltd. has gradually developed from a single mechanical equipment manufacturer to a high-tech enterprise with full-process technology integrating scientific research, design, manufacturing, installation, commissioning, and guarantee operation. It is environmentally friendly. , Building materials, mining and metallurgical process technology and equipment R & D and production capacity of a comprehensive company.

Hot Searches