- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Length:

-

3600/7200mm

-

Working Temperature:

-

1260

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

3%(24 Hours)

-

Thermal Conductivity:

-

0.09-0.2

-

Model Number:

-

UET128-25

-

Brand Name:

-

UET

-

Place of Origin:

-

Hebei, China

-

Product name:

-

HZ Ceramic Wool Insulation Blanket

-

Application of ceramic fiber blanket:

-

Boiler Insulation

-

Raw material:

-

Ceramic Fiber Spun Bulk

-

Classification Temperature:

-

1260/1260/1350/1430

-

Package:

-

Woven Bag or carton box

-

Color:

-

White Pure

-

Certificate:

-

ISO9001 ISO14001

-

Brand:

-

UET

-

Bulk density:

-

64/80/96/128/160kg/m3

-

OEM:

-

Avaible

Quick Details

-

Thickness:

-

10-50mm

-

Width:

-

610mm

-

Chemical Composition:

-

AL2O3+SIO2

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Length:

-

3600/7200mm

-

Working Temperature:

-

1260

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

3%(24 Hours)

-

Thermal Conductivity:

-

0.09-0.2

-

Model Number:

-

UET128-25

-

Brand Name:

-

UET

-

Place of Origin:

-

Hebei, China

-

Product name:

-

HZ Ceramic Wool Insulation Blanket

-

Application of ceramic fiber blanket:

-

Boiler Insulation

-

Raw material:

-

Ceramic Fiber Spun Bulk

-

Classification Temperature:

-

1260/1260/1350/1430

-

Package:

-

Woven Bag or carton box

-

Color:

-

White Pure

-

Certificate:

-

ISO9001 ISO14001

-

Brand:

-

UET

-

Bulk density:

-

64/80/96/128/160kg/m3

-

OEM:

-

Avaible

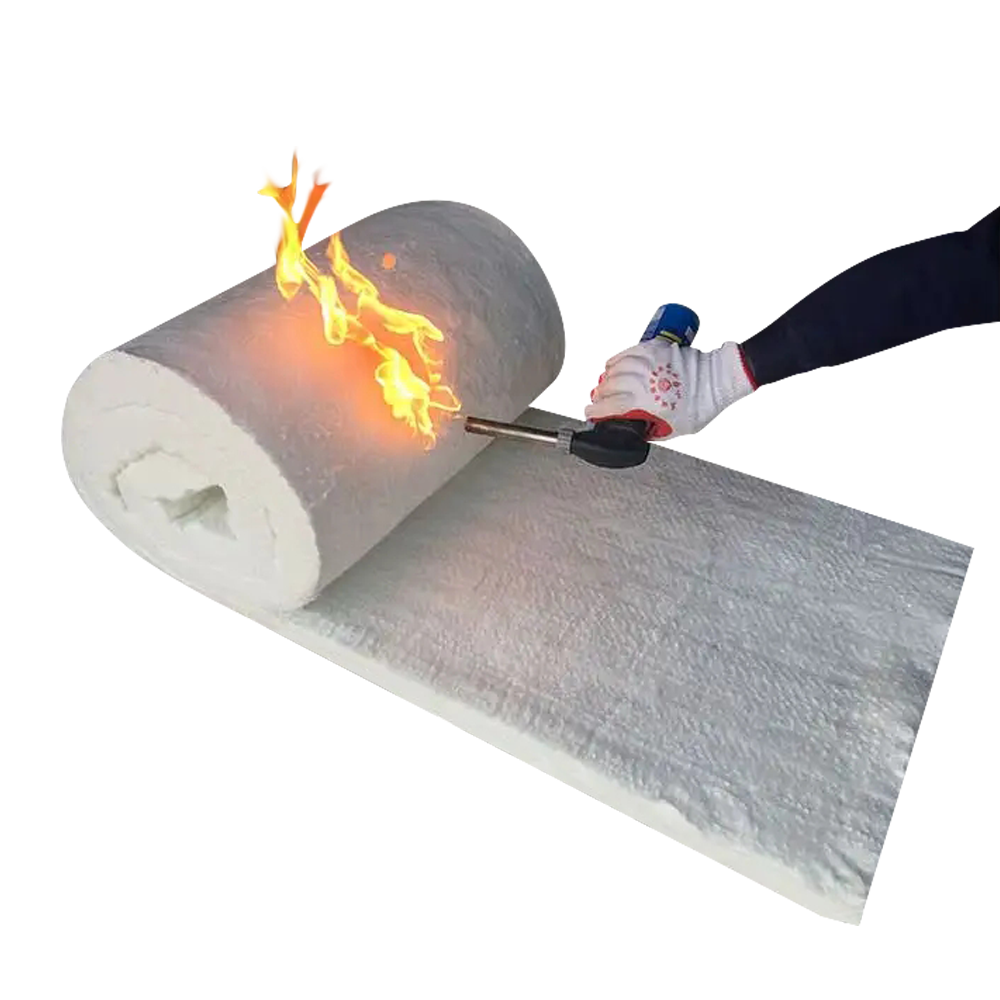

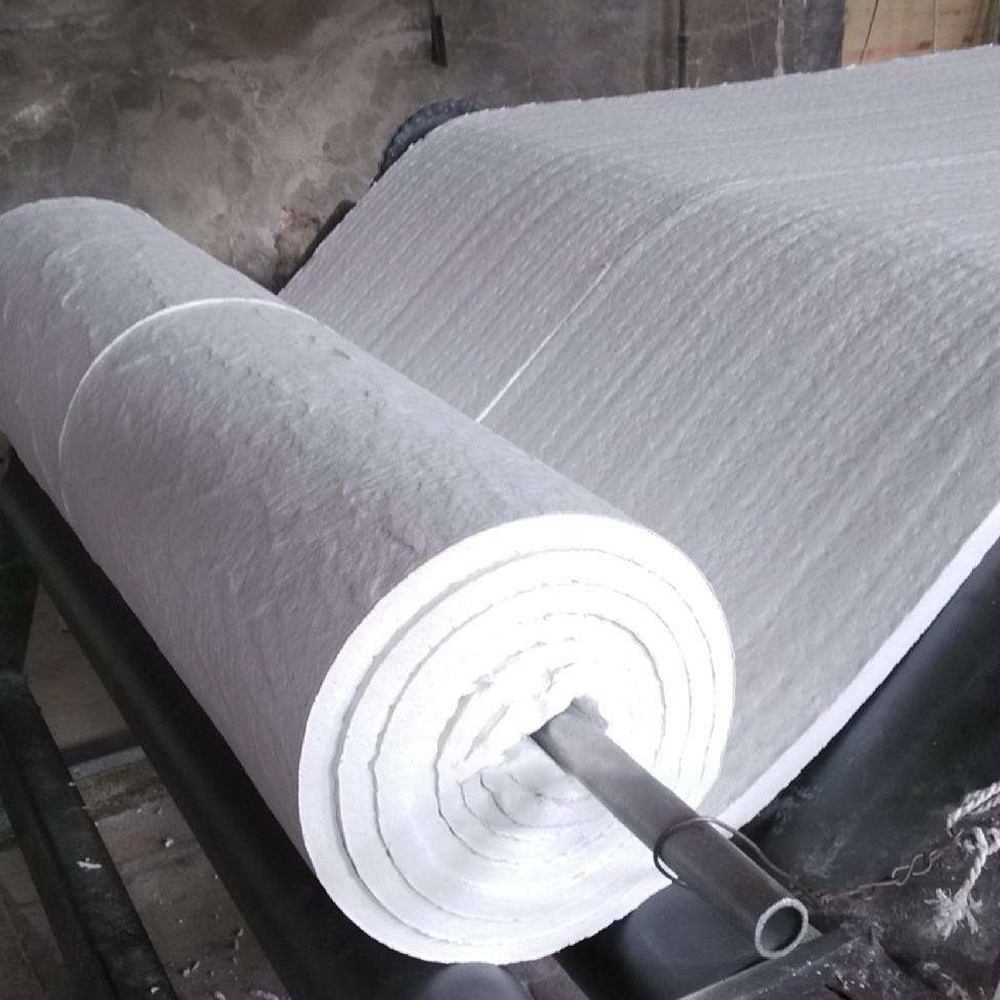

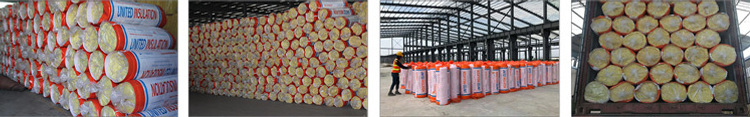

United Insulation Ceramic Fiber Blanket is made of high quality ceramic fiber spun bulk by using double inside needling methods which improve the tensile strength and the flatness of the cermic fiber blanket.

UET ceramic fiber blanket contains no organic binders which guarantee the stability and constructability of the ceramic fiber blanket at both high temperature and low temperature.

It is widely used for pipe and equipments of pyroelectricity, petroleum-chemical, boats, building, machines, boilers, etc. with the performance of fire prevention, heat insulation, sound absorption, and other so many technical features.

| 1050 Common | 1260 STD | 1260HP | 1400 | 1450HZ | ||

| Operation Temp(℃) | 950℃(1742℉) | 1050℃(1922℉) | 110 0℃(2012℉) | 1200℃(2192℉) | 1350℃(2462℉) | |

| Density(kg/m3) | 64-160 | |||||

| Permanent Change on Heating(%) | 950℃*24h ≤-3 | 1050℃*24h ≤-3 | 110 0℃*24h ≤-3 | 1200℃*24h ≤-3 | 1350℃*24h ≤-3 | |

| Coefficient of Heat Conductivity | 0.15(600℃) 0.22(800℃) | 0.12(600℃) 0.20(800℃) | 0.12(600℃) 0.20(800℃) | 0.12(600℃) 0.20(800℃) | 0.12(800℃) 0.20(1000℃) | |

|

Tensile Strength(Thickness 25mm)

|

≥0.04 | ≥0.05 | ≥0.05 | ≥0.04 | ≥0.06 | |

| Chemical content | Al2O3(%) | 44 | 45-46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2(%) | ≥96 | ≥98 | ≥99 | ≥99 | - | |

| ZrO2(%) | - | - | - | - | 15-17 | |

| Al2O3+SiO2+ZrO2(%) | - | - | - | - | ≥99 | |

| Fe2O3(%) | ≤1.0 | ≤0.8 | ≤0.2 | ≤0.2 | ≤ ≤0.2 | |

| Na2O+K2O(%) | ≤0.4 | ≤0.3 | ≤0.2 | ≤0.2 | ≤0.2 | |

| CaO+MgO(%) | ≤0.3 | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

| Product name | 1260 ceramic fiber blanket | |

| Classification temperature | 1260℃(2300℉) | |

| Density | 64kg/m3, 96kg/m3, 128kg/m3 | |

| Size |

15000*610/1220*10mm 14400/14640*610/1220*12.5mm 7200/7320*610/1220*20mm 7200/7320*610/1220*25mm 5000*610/1220*30mm 4500*610/1220*25mm 3600/3660*610/1220*50mm accept customized |

PACKAGING

• Inner plastic bag, outside carton box

• Inner plastic bag, outside carton box, then pallets

GB/T17795-2008, GB/T13350-2008, GB/T23932-2009, ASTM C653, ASTM C665, ASTM C1104

GB 18580-2017

• Excellent heat insulation

• Low thermal conductivity

• Excellent chemical stability

• Excellent thermal insulation, fireproof and sound absorption

| Keep Cool | Keep Warm | Fire Proof | Moisture Proof | Noise Control | Sustainbility | Save Cost | Health Safe |

• High temperature tube heat insulation material;

• Refining and petrochemical industry;

• Ceramic industry--Kiln car insulation and seals, Continuous and batch kilns;

• Sound-absorbing or high temperature filtration materials.