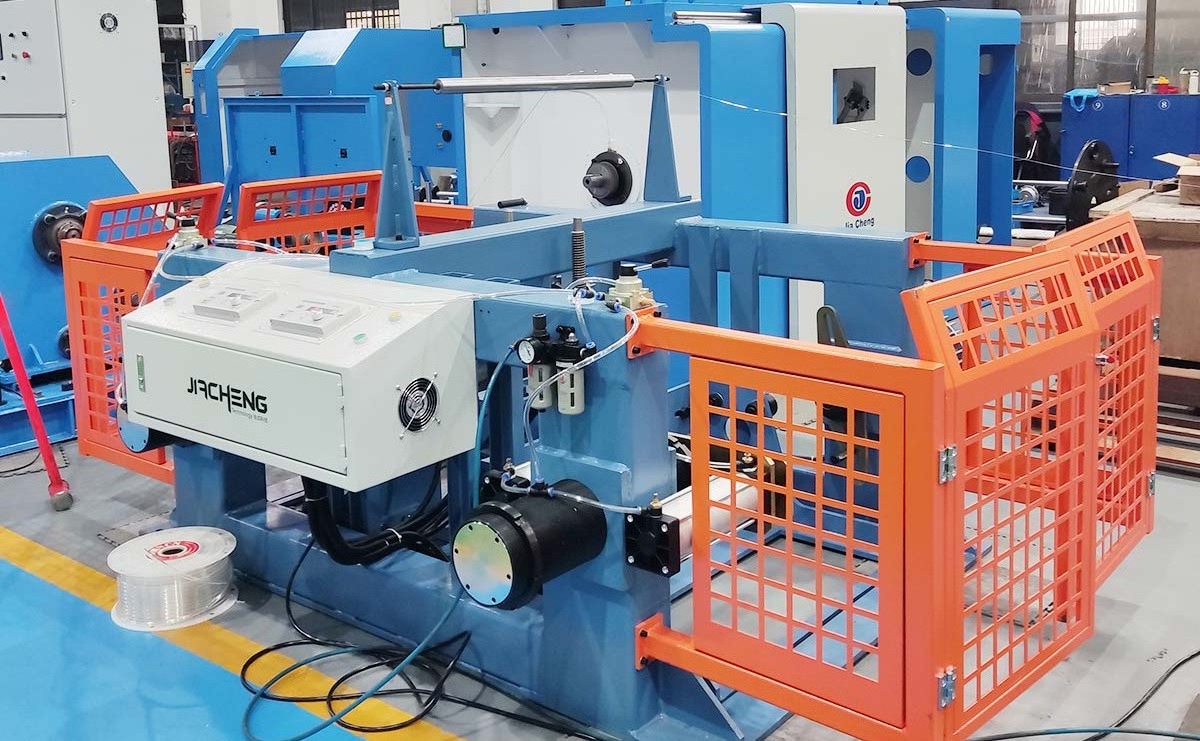

precise design of the screw, durable, non-mucus, not take off chrome, change color quickly, with high capacity, high quality, the

concentricity of wire is more than 90%, with high precision

±

0.03, With touch screen+PLC control, easy operation, more hommization.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JCJX

-

Usage:

-

Extruding

-

Function:

-

Apply to the insulation of wire&cable with PVC, LDPE, NYLON, TPU

-

Certification:

-

CE/ISO9001:2008

-

Key selling point:

-

Change color quickly

-

Application industry:

-

Manufacturing Plant Cable Making Industry

-

Core component:

-

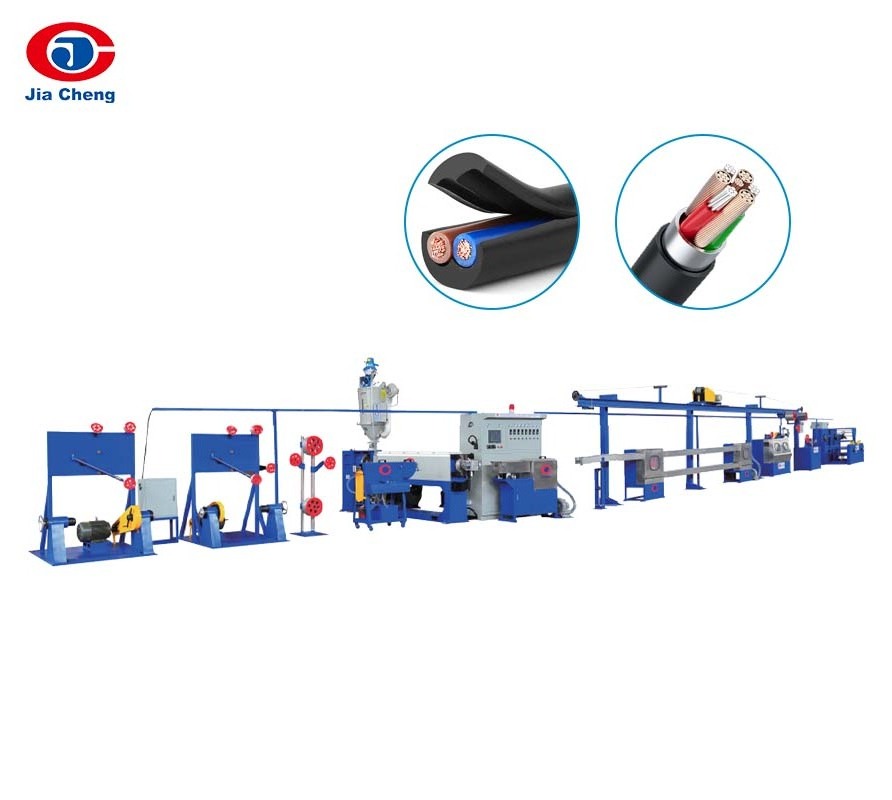

Pay-off+ Extruding main machine+ Water tank+ Tractor+ Take-up

-

Quality:

-

High efficiency

-

Automatic degree:

-

Full automatic

-

Minimum Order Quantity:

-

1 Pcs

-

Price:

-

Negotiation

Quick Details

-

Use:

-

Extruding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIACHENG

-

Model Number:

-

JCJX

-

Usage:

-

Extruding

-

Function:

-

Apply to the insulation of wire&cable with PVC, LDPE, NYLON, TPU

-

Certification:

-

CE/ISO9001:2008

-

Key selling point:

-

Change color quickly

-

Application industry:

-

Manufacturing Plant Cable Making Industry

-

Core component:

-

Pay-off+ Extruding main machine+ Water tank+ Tractor+ Take-up

-

Quality:

-

High efficiency

-

Automatic degree:

-

Full automatic

-

Minimum Order Quantity:

-

1 Pcs

-

Price:

-

Negotiation

Product Overview

High Speed Wire Insulation Production Line

The high-speed core wire insulation production line is a key equipment specially used to produce insulated core wires in communication cables and data cables. It processes bare copper wire or other conductor materials into core wires with insulating layers through a series of precise processes for subsequent cable manufacturing. The entire production process is efficient and highly automated, ensuring product quality and production efficiency.

The production process mainly includes the following key steps:

Wire drawing:

First, the raw material conductor (such as copper rod) goes through the drawing process and is stretched to the required fineness. This step has a significant impact on the diameter and surface quality of the wire.

Insulation extrusion:

The drawn conductor enters the insulation extrusion machine. During this process, the insulation material (such as PVC, PE, XLPE, etc.) passes through the screw extruder head and is tightly wrapped around the conductor to form an insulation layer. This step has strict requirements on the uniformity and thickness of the insulation layer.

Series wire

: The insulated core wire may need to go through a series wire process to ensure that the insulation layer reaches highly precise geometric dimensions and optimal quality. This step is critical to improving wire performance.

Physical foaming or chemical foaming:

For some cables with special requirements, such as coaxial cables, the insulation layer may need to undergo physical foaming or chemical foaming treatment to obtain better electrical performance and flexibility.

High-speed extrusion:

In the high-speed extrusion process, the wire passes through the extruder and is continuously produced at high speed while maintaining the uniformity of the insulation layer and the concentricity of the wire.

FEATURES AT A GLANCE

|

Type

|

JCJX-30

|

JCJX-40

|

JCJX-50

|

JCJX-60

|

JCJX-70

|

|

Screw Dia.(mm)

|

Ø30

|

Ø40

|

Ø50

|

Ø60

|

Ø70

|

|

Screw L/D Ratio

|

25:1

|

25:1

|

25:1

|

25:1

|

25:1

|

|

Extrusion Capacity(kg/h) PVC

|

25

|

40

|

80

|

100

|

130

|

|

Extrusion Capacity(kg/h) LDPE

|

16

|

20

|

40

|

53

|

86

|

|

Extrusion Capacity(kg/h) PP

|

13

|

17

|

34

|

41

|

68

|

|

Main Motor Power

|

5.5

|

7.5

|

11

|

18.5

|

22-37

|

|

Total Power

|

21

|

24

|

28

|

42

|

50

|

|

Finshed Dia.(mm)

|

0.2-1

|

0.4-3

|

0.8-5

|

1-8

|

2-12

|

|

Pay-off Bobbin Size(mm)

|

300/400

|

300/500

|

400/630

|

500/630

|

500/630

|

|

Pay-off Power

|

2.2

|

3.7

|

3.7

|

3.7

|

3.7

|

|

Haul-off Unit Type

|

Capastan

|

Capastan

|

Capastan

|

Capastan

|

Capastan

|

|

Haul-off Unit Power

|

1.5

|

2.2

|

2.2

|

3.7

|

3.7

|

|

Accumulater Length(m)

|

220

|

220

|

220

|

220

|

220

|

|

Take-up Bobbin Size(mm)

|

400/500

|

400/630

|

400/630

|

500/630

|

630/800

|

|

Take-up Power

|

2.2

|

2.2

|

2.2

|

2.2

|

3.7

|

|

Line Speed(m/min)

|

10-650

|

10-650

|

10-650

|

10-650

|

10-500

|

|

Dimension(m) (L*W*H)

|

20*1.5*2.1

|

20*1.6*2.1

|

20*1.7*2.1

|

20*2.5*2.1

|

25*2.5*2.1

|

|

Weight(T)

|

5

|

6

|

8

|

8

|

8.5

|

|

Type

|

JCJX-80

|

JCJX-90

|

|

Screw Dia.(mm)

|

Ø80

|

Ø90

|

|

Screw L/D Ratio

|

25:1

|

25:1

|

|

Extrusion Capacity(kg/h) PVC

|

200

|

240

|

|

Extrusion Capacity(kg/h) LDPE

|

122

|

133

|

|

Extrusion Capacity(kg/h) PP

|

96

|

124

|

|

Main Motor Power

|

30-55

|

37-75

|

|

Total Power

|

65

|

75-113

|

|

Finshed Dia.(mm)

|

3-25

|

5-35

|

|

Pay-off Bobbin Size(mm)

|

500/630

|

630/800

|

|

Pay-off Power

|

5.5/7.5

|

7.5/11

|

|

Haul-off Unit Type

|

Capastan

|

Capastan

|

|

Haul-off Unit Power

|

5.5

|

5.5

|

|

Accumulater Length(m)

|

220

|

220

|

|

Take-up Bobbin Size(mm)

|

800/1000

|

630/1250

|

|

Take-up Power

|

3.7

|

5.5

|

|

Line Speed(m/min)

|

10-350

|

10-250

|

|

Dimension(m) (L*W*H)

|

25*3.2*2.1

|

30*3.6*2.1

|

|

Weight(T)

|

7-9

|

9-12

|

Hot Searches