- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Contrust

-

Voltage:

-

380V/220V customizable

-

Power:

-

5.5-22kW

-

Dimension(L*W*H):

-

customizable

-

Weight:

-

1500 kg

-

Features:

-

full automatic

-

Name:

-

Horizontal Spiral Ribbon Mixer

-

Keyword:

-

Simple Dry Mortar Production Line

-

Function:

-

Helical ribbon feed blender

-

Type:

-

Dry Powder Mixer

-

Mixer Type:

-

Wall Putty Mixer

-

Advantage:

-

Convenient Operation

-

Productivity:

-

1-5ton/hour

-

Automatic:

-

Full-automatic

-

Ceramic adhesive:

-

Mortar/ Gypsum/ Ceramic Tile Production

-

Raw material:

-

Sand Cement Additives

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

dry mortar production

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Contrust

-

Voltage:

-

380V/220V customizable

-

Power:

-

5.5-22kW

-

Dimension(L*W*H):

-

customizable

-

Weight:

-

1500 kg

-

Features:

-

full automatic

-

Name:

-

Horizontal Spiral Ribbon Mixer

-

Keyword:

-

Simple Dry Mortar Production Line

-

Function:

-

Helical ribbon feed blender

-

Type:

-

Dry Powder Mixer

-

Mixer Type:

-

Wall Putty Mixer

-

Advantage:

-

Convenient Operation

-

Productivity:

-

1-5ton/hour

-

Automatic:

-

Full-automatic

-

Ceramic adhesive:

-

Mortar/ Gypsum/ Ceramic Tile Production

-

Raw material:

-

Sand Cement Additives

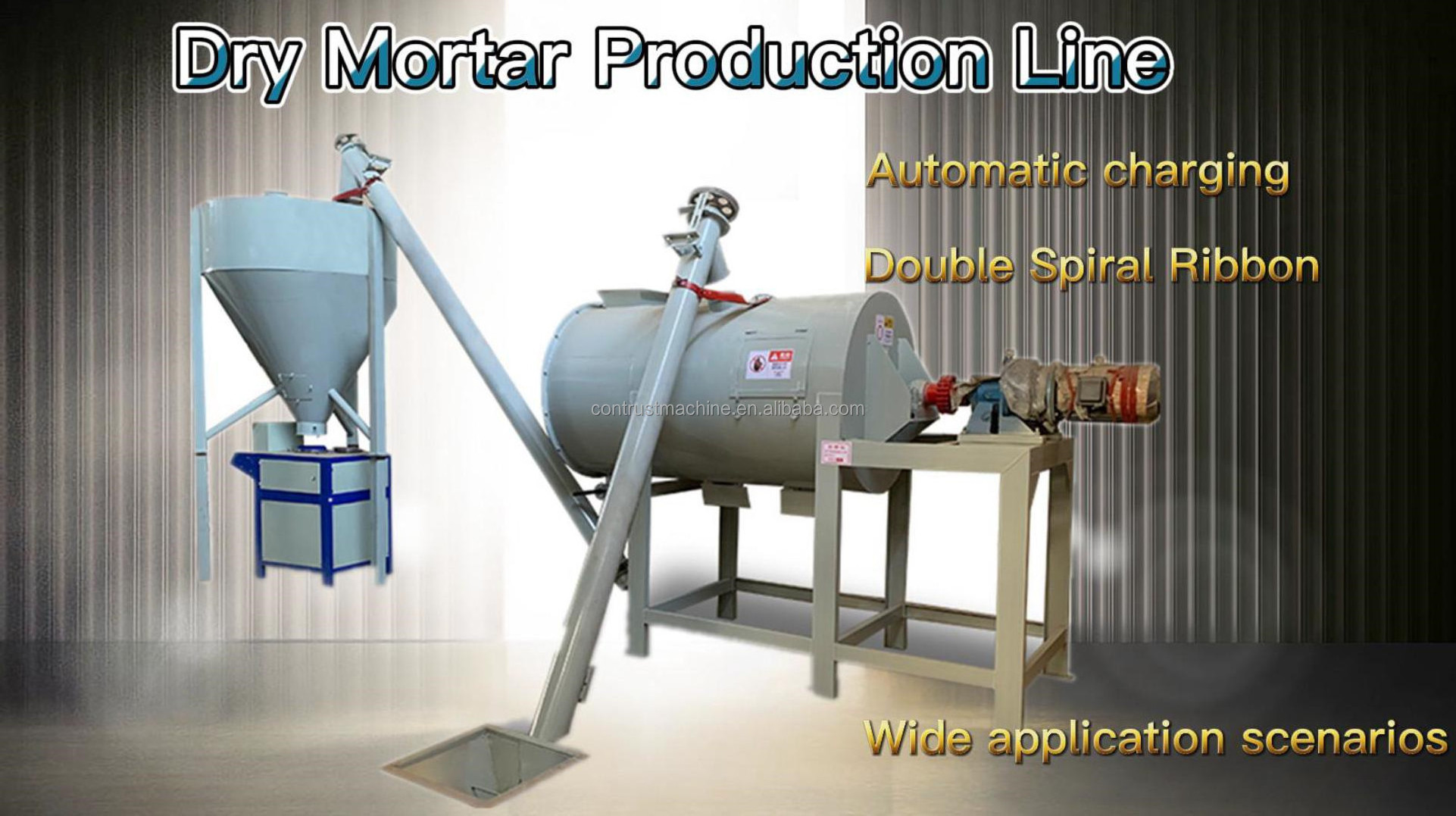

Products Description

Dry Mortar Production Line

The simple and practical small type dry mortar plant is designed based on the traditional mixer, is added a material conveying system, a storage bin, and an automatic filling machine. The well-mixed materials will go into the storage bin via material conveying pipe, and the mixer may be fed consecutively and work continuously in flow line production, but the equipment is not over 4 meters high, thus solving the problem of heightening the workshop. Moreover, it may realize automatic metering and filling, hence, it may not only save time and energy but also may be more accurate. Requires little investment, but it may load, weight, and package the materials automatically, no wonder, it is a simple but practical production line suit for diversified usage scenarios.

Specification

|

Model

|

Capacity(L)

|

Size(M)

|

Motor power(kW)

|

|

DP500

|

500L

|

2.1m*0.78m*1.6m

|

4kW

|

|

DP700

|

700L

|

2.1m*0.83m*1.92m

|

5.5kW

|

|

DP1500

|

1500L

|

2.8m*1.01m*2.1m

|

7.5kW

|

|

DP2100

|

2100L

|

3m*1.1m*2.2m

|

15kW

|

|

DP3200

|

3200L

|

3.2m*1.31m*2.4m

|

18.5kW

|

|

DP4300

|

4300L

|

3.5m*1.36m*2.5m

|

22kW

|

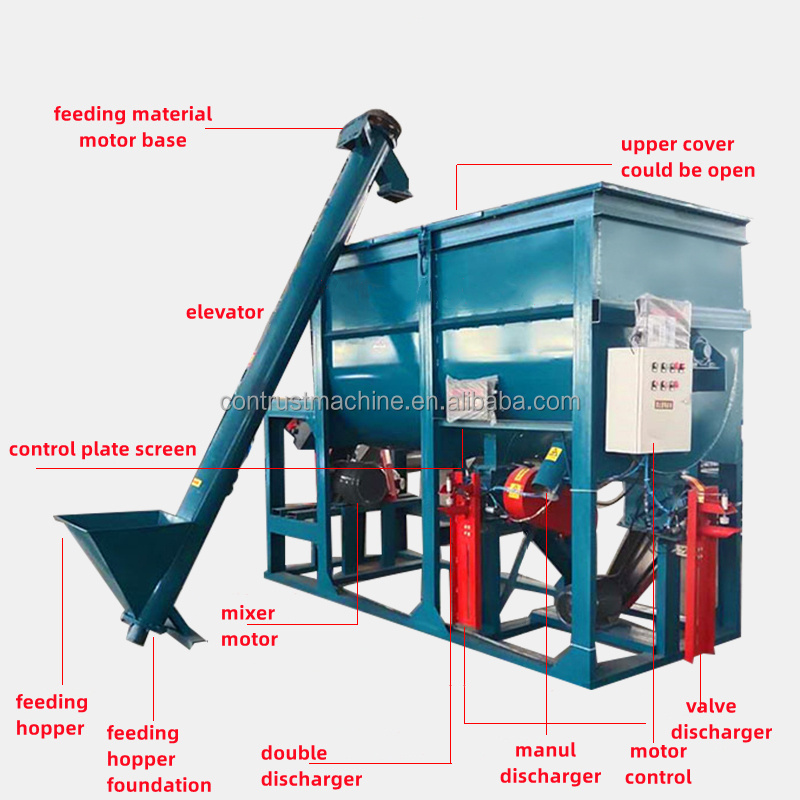

Details Images

Motor

And gear reducer.

It can provide strong power and smooth operation.

Shaft end link

Mixing

helix

Control cabinet

Instrument

Discharge measurement

save working, labor and money.

Screw feeding material

Packing machine

Advantages

The gap between the spiral ribbon and the inner wall of the casing is adjustable, with smooth operation, low noise, long service life, easy installation and wide use.

No mixing blind angle, mixing speed is faster compared with vertical mixing machine, and the mixed material uniformity is high.

Strong adaptability, not only can mix the materials with strong scattering, but also can mix the materials with poor scattering and large adhesion.

The part in contact with the material is made of stainless steel or carbon steel with anti-corrosion treatment.

The motor of this machine drives the pulley and reducer transmission. Avoid the overflow of finished material caused by the high speed of the mixer when putting the material.

The whole machine covers a small area and is more convenient to install and use.

The factory has the ability to customize the machine for you, the actual situation of the machine can be customized according to your site height and area requirements, mixing material properties, mixing speed.

No mixing blind angle, mixing speed is faster compared with vertical mixing machine, and the mixed material uniformity is high.

Strong adaptability, not only can mix the materials with strong scattering, but also can mix the materials with poor scattering and large adhesion.

The part in contact with the material is made of stainless steel or carbon steel with anti-corrosion treatment.

The motor of this machine drives the pulley and reducer transmission. Avoid the overflow of finished material caused by the high speed of the mixer when putting the material.

The whole machine covers a small area and is more convenient to install and use.

The factory has the ability to customize the machine for you, the actual situation of the machine can be customized according to your site height and area requirements, mixing material properties, mixing speed.

Application

● What is the Minimum Quality Order?

-- The MOQ is 1 set. If you order large amount, you will get discount.

● What is the payment terms?

-- T/T, L/C, Western Union,credit card.

● Which kind of shipment do you support?

-- Sea transportation, air transportation and international express.

● When will you deliver the machine?

-- 7-15 workdays after receiving the balance payment.

● Do you supply training and after-sale service?

-- Yes, we will supply installation and training on site or online. Also we have a professional service team that can solve problems as fast as possible.

● What about the warranty time of machine?

-- 12 months after shipment.

-- The MOQ is 1 set. If you order large amount, you will get discount.

● What is the payment terms?

-- T/T, L/C, Western Union,credit card.

● Which kind of shipment do you support?

-- Sea transportation, air transportation and international express.

● When will you deliver the machine?

-- 7-15 workdays after receiving the balance payment.

● Do you supply training and after-sale service?

-- Yes, we will supply installation and training on site or online. Also we have a professional service team that can solve problems as fast as possible.

● What about the warranty time of machine?

-- 12 months after shipment.

Hot Searches