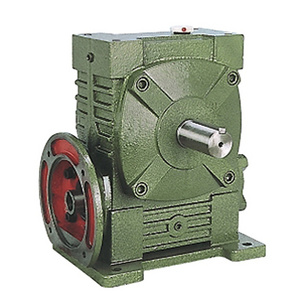

◆ Installation method: base installation, flange installation, torque arm installation.

◆ Reduction ratio: basic type two level 4.3-25.3, three level 28.2-273, combined to 18509.

◆ The rotation direction of the input and output of the basic two-stage is the same, and the three-stage is opposite; please consult when combining.

◆ Output mode: hollow shaft output or solid shaft output.

◆ Average efficiency: Level 2 96%, Level 3 94%, F/CR average efficiency 85%.