- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dingbo

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

9000mm*1200mm*800mm

-

Weight:

-

5000 kg

-

Control system:

-

PLC(imported Brand)

-

Forming Speed:

-

16-20m/min

-

Feature:

-

Automation

-

Roller material:

-

45# Steel

-

Cutter Material:

-

Cr12Mov

-

Service:

-

1 Year Guarantee

-

Decoiler:

-

Manual

-

Color:

-

Client's Request

-

Usage:

-

Building Projects

Quick Details

-

Marketing Type:

-

New Product 2022

-

Production Capacity:

-

0-20m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Dingbo

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

9000mm*1200mm*800mm

-

Weight:

-

5000 kg

-

Control system:

-

PLC(imported Brand)

-

Forming Speed:

-

16-20m/min

-

Feature:

-

Automation

-

Roller material:

-

45# Steel

-

Cutter Material:

-

Cr12Mov

-

Service:

-

1 Year Guarantee

-

Decoiler:

-

Manual

-

Color:

-

Client's Request

-

Usage:

-

Building Projects

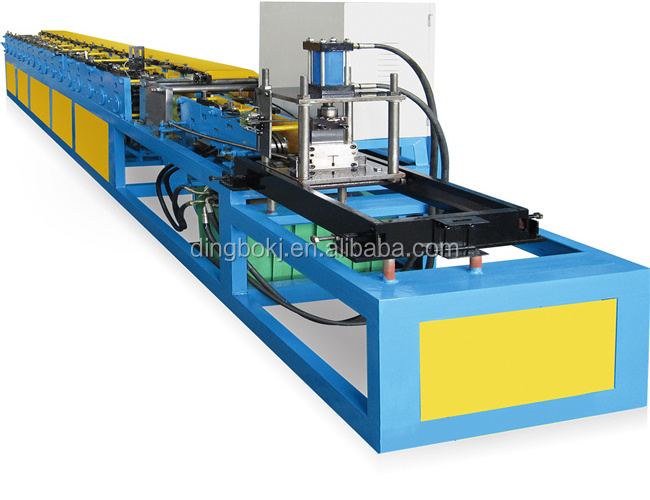

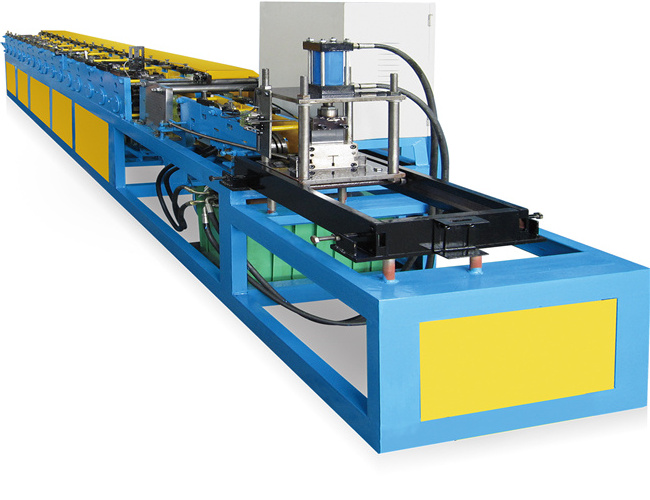

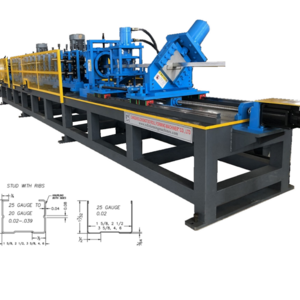

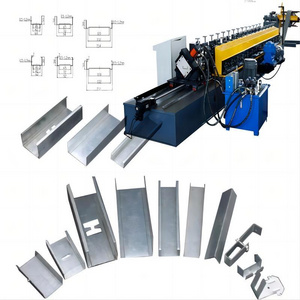

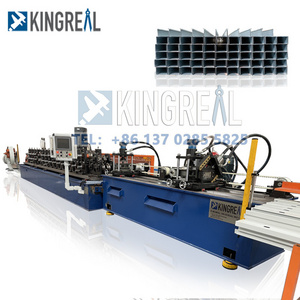

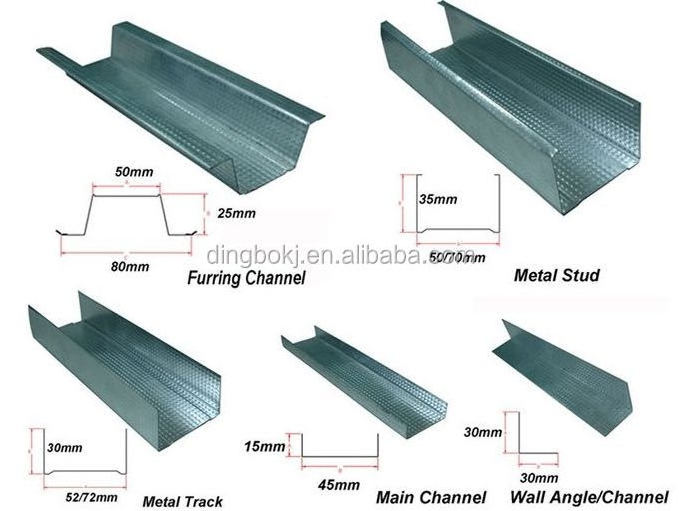

Stud and track roll forming machine

Product Descriptions

Stud tracks are widely used in luxury villas, high-end hotels, office buildings and shopping malls. It is sturdy, durable, and highly resistant to corrosion. It is also popular with construction units and construction units in terms of price, reducing the quality concerns of the project during construction, and frequent maintenance due to material quality problems during use. Greatly reduce the construction cost and various troubles caused by maintenance during use.

Version to design

Working Flow

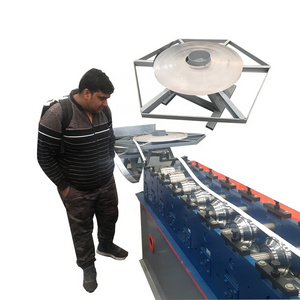

Decoiler -- Feeding -- Straighten -- Punching --Roll forming -- Shear -- Output

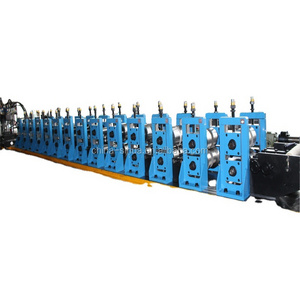

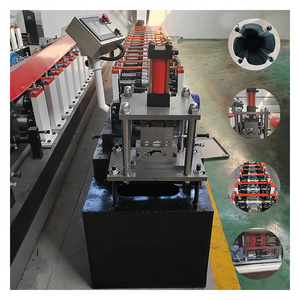

Product Parameters

|

|

Items |

Specifications |

|

Material of coil |

Thickness |

0.3-1mm galvanized steel |

|

De-coiler |

Weight |

3 ton manual |

|

Forming system |

Rolling Speed |

0-15m/min 0-20m/min (Depending on the customer) |

|

Embossing |

At sides |

|

|

Roller Stations |

About 13 stations forming |

|

|

Roller Material |

Cr40 Steel with quenching |

|

|

Shaft Material |

45# Steel Diameter 60mm shaft |

|

|

Motor Power |

5.5 kw |

|

|

Hydraulic cutting Power |

3 kw |

|

|

Cutting system |

Material of cutting |

CR12 with quench treatment |

|

Hardness |

HRC58-62 |

|

|

Tolerance |

+-1.5mm |

|

|

Cutting blade |

3 pieces of cutting blade |

|

|

Electrical control system |

Electric Source |

380V, 50HZ,3 phase |

|

Control System |

PLC |

|

|

|

Weight |

About 3 tons |

|

|

Way Of Drive |

1 inch single chain |

|

|

Size of machine |

Length 5500mm* Width 600mm*Height 800m |

Main Components

|

3 ton passive de-coiler |

1 set |

|

Main roll forming machine |

1 set |

|

Punching device |

1 set |

|

Cutting device |

2 sets |

|

PLC Control box |

1 unit |

|

Hydraulic station |

1 unit |

|

Out table |

2 units |

|

Safety cover |

1 unit(Optional) |

Pictures

We will order container before the delivery date, arranging the land before customs declaration, and we inspect each part of the machine before shipment. We put the molding machine into the container for comprehensive fixing, and the transportation safety is very high. We always remind drivers to pay attention to road safety.

1. Q: What's the warranty period? (24hours online)

12 months warranty period, starting from the date of the successful installation and commissioning of the equipment at the Buyer’s Installation site. During which all parts damaged because of quality problem will be changed for free.

2. Q: Do you have installation and commissioning service?

A. If buyers come to our factory to inspect, the training to install and operate is provided face to face. If not, manual and video is provided to show how to install and operate.

B. If buyer need we will send technician to buyer site to do installation and commissioning and training.

C . installation and commissioning cost: One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100/per day and visa fee, air tickets fee, accommodation and food, necessary communication, etc.

(Normally ,It takes about a week to install )

3. Q: What’s your after-sales s ervice ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

4. Q: What's your delivery time ?

Normally we can finish production and testing w ithin 45- 7 0 days after receiving deposit . Some machines in stock, can be delivered at any time

5 . Q: You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

6 . Q: Do you provide customized machine ?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

7. Q: How to place order ?

Inquiry---confirm the profile drawings and technical specification and price ----confirm the PI---arrange the deposit or L/C--- start production-- do inspection--- Shipment

8.What are your terms of payment ?

First payment: 30 % by T/T, second payment: 70% by T/T, after the successful inspection at seller’s workshop, and before delivery.