- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

500KG

-

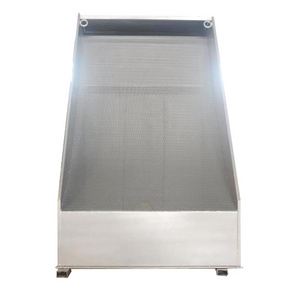

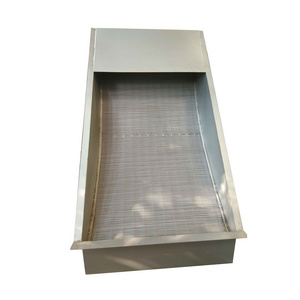

Size:

-

1500x600x1300mm

-

Weight (KG):

-

450 kg

-

Certification:

-

ce

-

Capacity:

-

customized

-

Flow rate:

-

10m3/h

-

Voltage:

-

customized

-

spacing:

-

1-20mm

-

effective width:

-

900mm

-

channel depth:

-

1000mm

-

install angle:

-

60-70 degree

Quick Details

-

Place of Origin:

-

shandong

-

Brand Name:

-

Turbo

-

Material:

-

plywood case, SS304

-

Weight:

-

500KG

-

Size:

-

1500x600x1300mm

-

Weight (KG):

-

450 kg

-

Certification:

-

ce

-

Capacity:

-

customized

-

Flow rate:

-

10m3/h

-

Voltage:

-

customized

-

spacing:

-

1-20mm

-

effective width:

-

900mm

-

channel depth:

-

1000mm

-

install angle:

-

60-70 degree

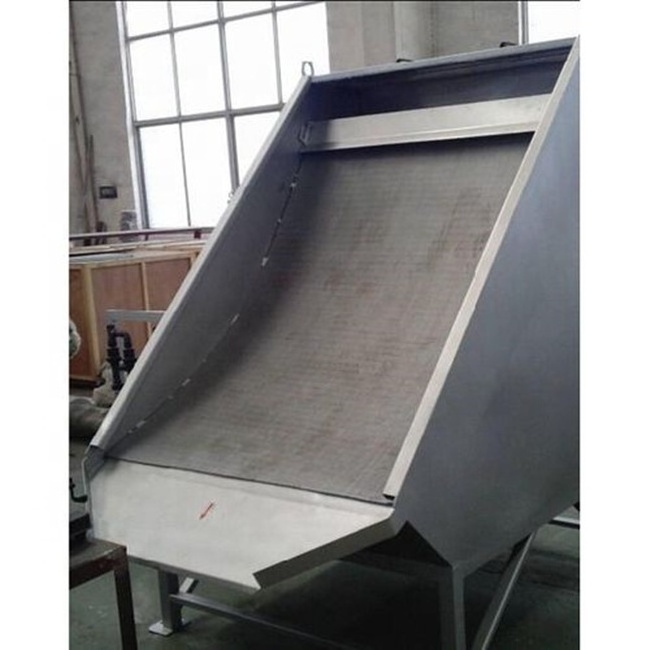

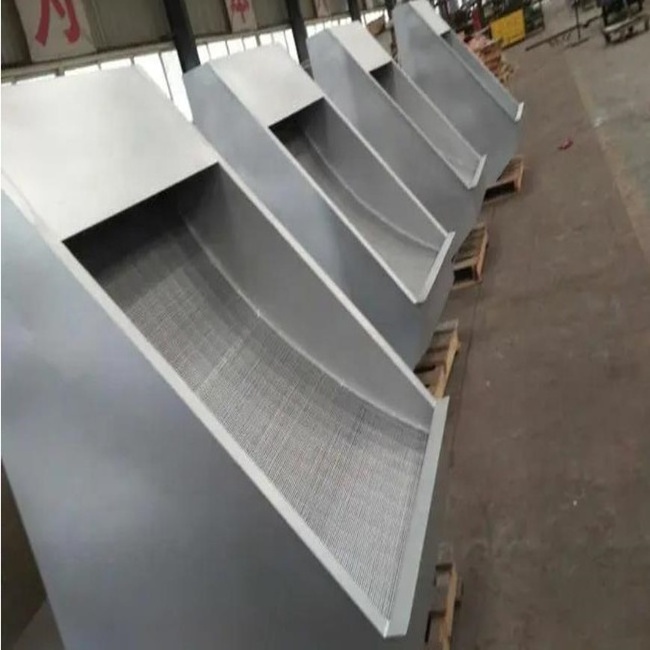

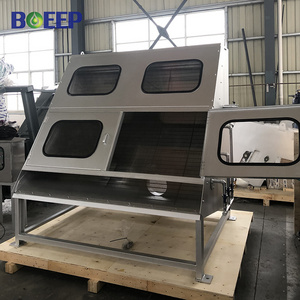

Hydraulic static screen

Also called curve screen, inclined screen , hydraulic screen etc;

Scope of application:

Suitable for a variety of different types, different sizes of wastewater treatment project. Remove floating, suspended solids, center of gravity, etc., as a primary treatment, the alternative to the pond, reduce post-processing work, strengthen the unblocked biological treatment process, save operating cost. Also used in a variety of solid-liquid mixture concentration;

Typical applicable industry:

1. Paper making waste water ----- recycle fiber , remove solids;

2. Tannery waste water------- remove fur and feather , oil grease etc solids ;

3. Slaughtering waste water------remove fur , oil grease , feces etc solids;

4. Municipal domestic sewage-----remove fur , sundries etc solids;

5. Alcohol, starch factory wastewater, removal plant fiber shell's, groceries and other solid objects etc;

6. Pharmaceutical factory, sugar refinery wastewater, remove all kinds of waste residue, such as plant shell's etc solids;

7. malt beer factory wastewater, removal of malt, bean curd and other solids;

8. Livestock fish farms - removing clutter of livestock MAO, excrement and solid content etc solids;

9. Fish and meat processing plant - gut, scales, ground meat, fat and other solid. Other such as the characteristic, textile, chemical, plastic processing plants, large factory, hotel, residential sewage etc pretreatment;

Working principle

The main body for wedge steel by precision made of stainless steel curved or flat filter sieve surface, to be processed waste water through the overflow weir evenly distributed to sloping screen and small gap due to the screen surface, smooth, on the back of the gap is big, catchment is smooth, not easy to block; Solid matter trapped, the filtered water flows out from a crack in the sieve plate and at the same time, under the action of a hydraulic solid matter is pushed to the sieve plate bottom into the aggregate bin (piece) of choose and buy, so as to achieve purpose of solid-liquid separation;

performance feature:

1. Utilize water flow own gravity working, no power consumption;

2. each unit with big treatment capacity;

3. not easy to block, convenient to wash;

4. whole machine matrial use stainless steel made, with high mechanical

Intensity, no easy deformation , long service life;

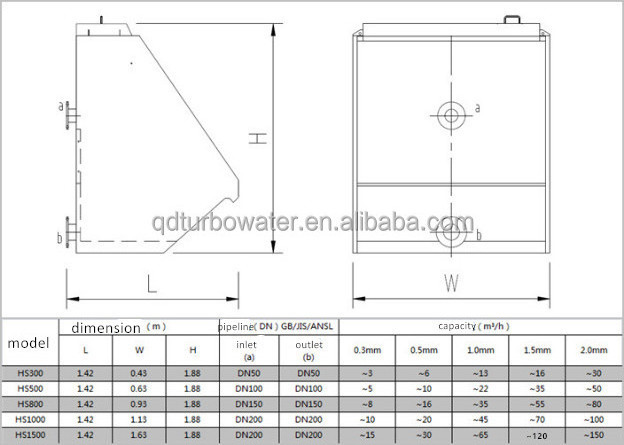

technical parameter:

other related product:

1.Q:Are you a factory or trading company?

A:We are a factory ,we have rich experience for manufac t uring water processing equipment for more than 20 ears.

2.Q:Where is your factory located?

A:Our factory is located in free trade area Huangdao district , Qingdao ,

3.Q:How to buy your idea products?

A:You can provide us your sewage sources,sewage quality ( COD, BOD, SS) , flow rate and ground area (connect us for more details) ;

4.Q:Do you have certificates?

A:Yes,we have CE, ISO9001, ISO14001,SGS certificate.

5.Q:Can you meet my special requirements or my products?

A:Yes,we have a professional design team.We can provide drawings according to your requirements.

6.Q: what is the pay ment term ?

A:T/T and L/C are acceptable ;

7.Q:What is the delivery time ?

A: within 10 wo r king days.It depends on order quantity ;

8.How to install after the equipments arriving destination?

A: We will provide detailed illustrations to you. And if need, we will send a technicians to guide for installation and debugging. after debugging equipment, we will teach your workers how to use it and how to maintain it.

9.Q:How to pack the products?

A:standard export package , such as plywood case,carton,plastic film etc;

10.Q:How to keep your equipments from corrosion?

A:We use the world-famous paint ,like Sigma Coatings ,Pain ,Bow, etc. What's more ,we paint strictly according to the standard process.

11.Q:How about the warranty?

A: If there is any malfunction of the equipment during the warranty period, our company promises to propose a solution within 24 hours. If it is caused by non-human causes, our company provides repairs free of charge and guarantees that the equipment is running well again.

After service

a.Provide equipment certification and installation operating instructions.

b . Provide one-year spare parts.

c.Provide technical advisory services.

d.Provide guidance staff for installation and commissioning.