- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

3-4blocks/min

-

Briquettes Length:

-

80mm

-

Operation Mode:

-

Highly Automated Cycle

-

Maximum Pressure:

-

2000Kn(200tons)

-

Main Motor Power:

-

15Kw

-

Briquettes Diameter:

-

60-80mm

-

Machine Weight:

-

18000kgs

-

Voltage:

-

200~680V, 3Ph, 50/60 Hz

Quick Details

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China (Mainland)

-

After-sales Service Provided:

-

Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Applied Material:

-

Aluminium,Copper,Brass, Iron,Steel Chips

-

Production Capacity:

-

3-4blocks/min

-

Briquettes Length:

-

80mm

-

Operation Mode:

-

Highly Automated Cycle

-

Maximum Pressure:

-

2000Kn(200tons)

-

Main Motor Power:

-

15Kw

-

Briquettes Diameter:

-

60-80mm

-

Machine Weight:

-

18000kgs

-

Voltage:

-

200~680V, 3Ph, 50/60 Hz

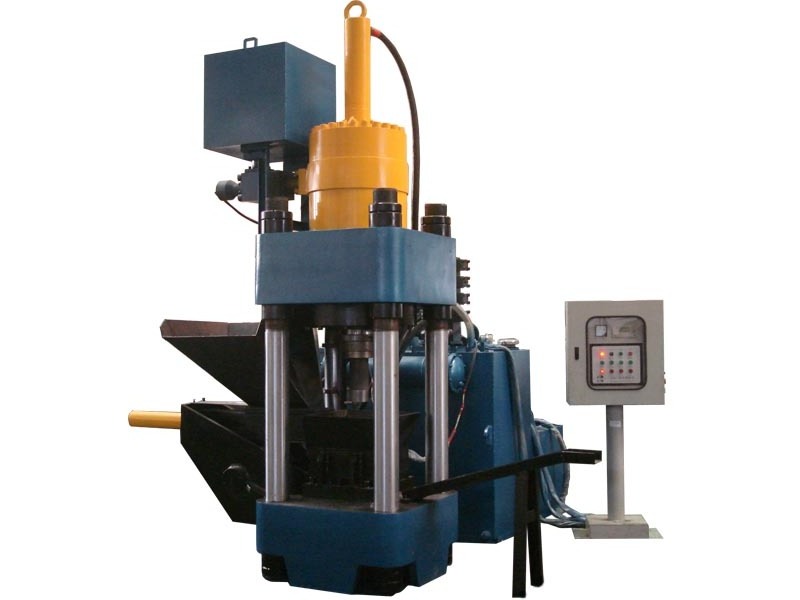

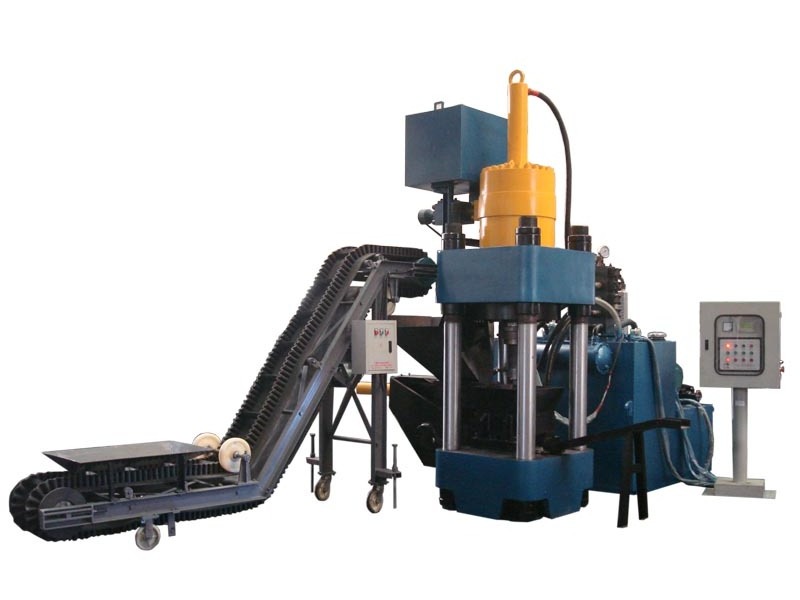

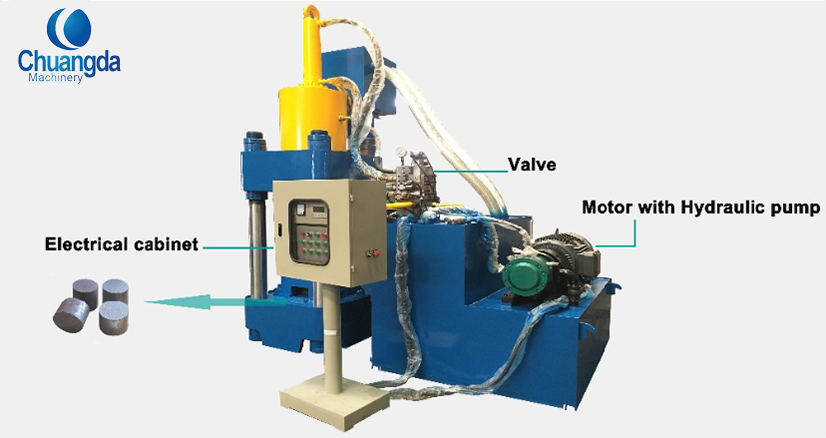

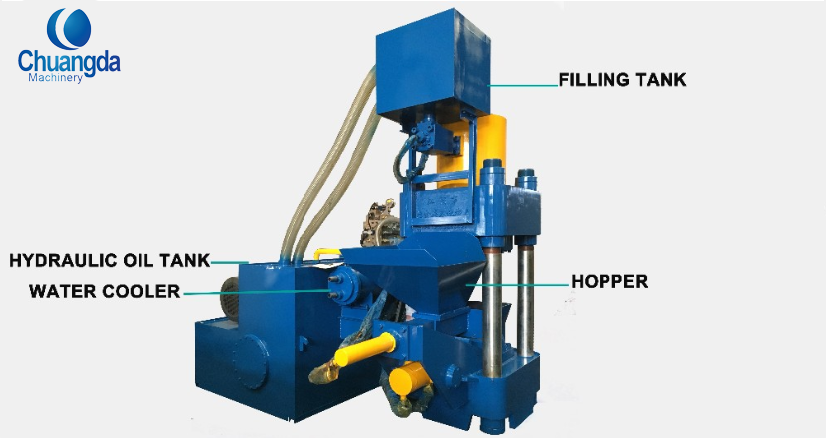

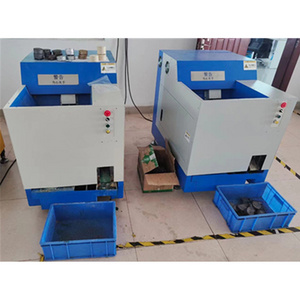

The

ECOHYDRAULIC

series of hydraulic briquetting presses are industrial machines designed to press metal chips into briquettes and operate in automatic mode.

Press Material:

Cast iron, aluminum, copper, steel, brass, zinc, bronze,titanium and magnesium, they are also suitable for treating a variety of other machining scraps.

Advantages for SBJ-500 Briquetting press machine:

1.The high pressure reached in the compression chamber allows creating high density briquettes.

2.Besides drastically reducing the volume of the machining chips, remove cutting fluids and create briquettes that.

3.In most cases,Briquettes can be placed directly in smelting furnaces.

4.This results in substantial economic benefits for companies that generate the scraps, companies that recycle metal scraps, and for foundries that process the scraps.

5.There are a large number of environmental benefits resulting from the briquetting process.

Steel chips

Steel Briquettes

Steel briquetting press can double the value you get for your steel scrap compared to loose chips or other recycling methods.

Aluminum Chips

Aluminum scrap metal, in the form of turnings, filings, chips and shavings, piling up on the equipment and floor. taking up the valuable floor space.

Aluminum Briquettes

Squeeze value from aluminum waste.

Compress aluminum scrap into dense briquettes and separate any fluids used in the metalworking process from the scrap metal.

Copper Chips

What do you do with your copper scrap? If you are like many manufacturers, the scrap is stored in your yard, then hauled away (at your expense) to be disposed of.

It's time to turn copper waste into an asset.

Copper Briquettes

ECOHYDRAULIC briquetting press to turn your scrap copper into compressed briquettes that are easier to handle, store and transport and can be sold for recycling.

SBJ SERIES TECHICAL SPECIFICATICONS

Established in 1989, Jiangyin Chuangda Machinery Factory is located in Jiangyin, an economic leading city in eastern China. As a professional manufacturer of hydraulic machineries, our company integrates with capabilities of design, research, development and production.

After 25 years of rapid development, we have become a well-known factory in domestic metal scrap recycling industry. Our products integrated horizontal metal baler are widely applied to the industries of metal recycling, foundry and metallurgy and are well received. Currently, we have two plants, the machining plant and the assembling plant, cover an area of 12000 square meters. There are more than 150 staff members, 17 professionals among them. And we have obtained 12 national patents so far.

Our main products are as follows, namely, hydraulic briquetting press, hydraulic integrated horizontal metal baler and hydraulic alligator shear. Our products are not only popular in China, but also have market shares in more than 20 Countries, for example, India, Russia, Ukraine, Japan, Thailand, Kuwait, Vietnam, Indonesia, Canada and Columbia.

For the sake of the benefits of our new and old customers, we will ceaselessly improve the product quality as much as we can.

1. If i will need to stay in your place for few days, is that possible to book the hotel for me?

It's always my pleasure, hotel booking service is available.

2. What is your minimum order quantity, can you send me samples?

Our minimum quantity is 1 set, as our product is machinery equipment, it's difficult to send you samples, however,we can send you catalog, warmly welcome you to come visit our company.

3. Which level of quality are your products?

We have got CE, ISO, SGS, TUV, SONCAP certificate so far.

4. What is the delivery time of your machine?

In general, the delivery time of our machine is about 30 days, customized machine will be delivered as the negotiation with our clients.

5. Can the machine be customized as our need, such as put on our logo?

Surely our machine can be customized as your need, Put on your logo is also available.

6. As the shipping period will take long time, how can you make sure the machine won't be broken?

Our machine is film wrapped, to make sure the machine can be delivered to our customer smoothly, we will use the steel wire to fix the machine with the container.

7. May i know which payment will be accepted by your company?

So far 100%T/T before shipment, and 30% deposit paid by T/T, balance paid by L/C are available.

8. About the after-sale service, how can you solve the problems occurred of your overseas customer in time?

The warranty of our machine is normally 12 months, during this period, we will arrange the international express immediately, to make sure the replace parts to be delivered as soon as possible.

9. After we placing an order, will you arrange the installation of the machine at present?

All the machines will be tested well before delivered, so almost of them can be used directly, also our machine are easy to be installed, if you customer needs our assistance, we will be pleased to arrange the installation, but all the cost will be be charged by you.