- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

sdr9-sdr26

-

Specification:

-

20MM-1600MM

-

Length:

-

11.8m 100 m or as request

-

Thickness:

-

2.6mm 3.5mm 4.5mm 5.6mm 6.8mm 8.4mm

-

Standard:

-

ISO CE

-

Color:

-

Black

-

Application:

-

Water Supply,Sewerage and Drainage,Mining

-

Diameter:

-

DN20mm-1600mm

-

Advantage:

-

Flexible,Durable,Chemical-resistant,Leak-Proof

-

Working pressure:

-

0.6Mpa-2.0Mpa

-

Sample:

-

Provide Samples

-

OEM:

-

Acceped

-

Delivery Time:

-

7-15 Days

-

Working Temperature:

-

-50°C to 90°C

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rayman

-

Model Number:

-

sdr9-sdr26

-

Specification:

-

20MM-1600MM

-

Length:

-

11.8m 100 m or as request

-

Thickness:

-

2.6mm 3.5mm 4.5mm 5.6mm 6.8mm 8.4mm

-

Standard:

-

ISO CE

-

Color:

-

Black

-

Application:

-

Water Supply,Sewerage and Drainage,Mining

-

Diameter:

-

DN20mm-1600mm

-

Advantage:

-

Flexible,Durable,Chemical-resistant,Leak-Proof

-

Working pressure:

-

0.6Mpa-2.0Mpa

-

Sample:

-

Provide Samples

-

OEM:

-

Acceped

-

Delivery Time:

-

7-15 Days

-

Working Temperature:

-

-50°C to 90°C

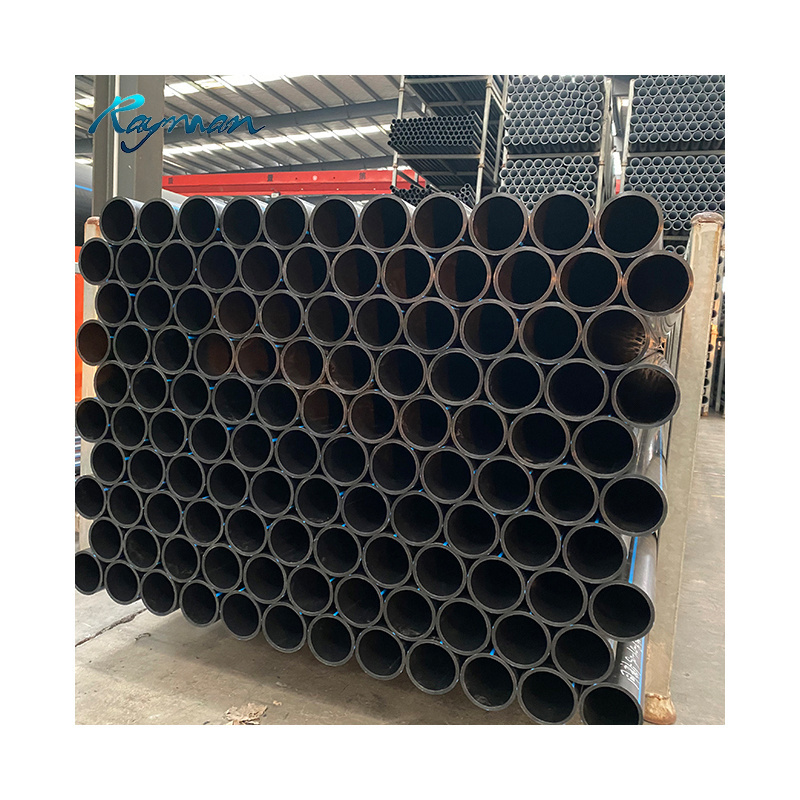

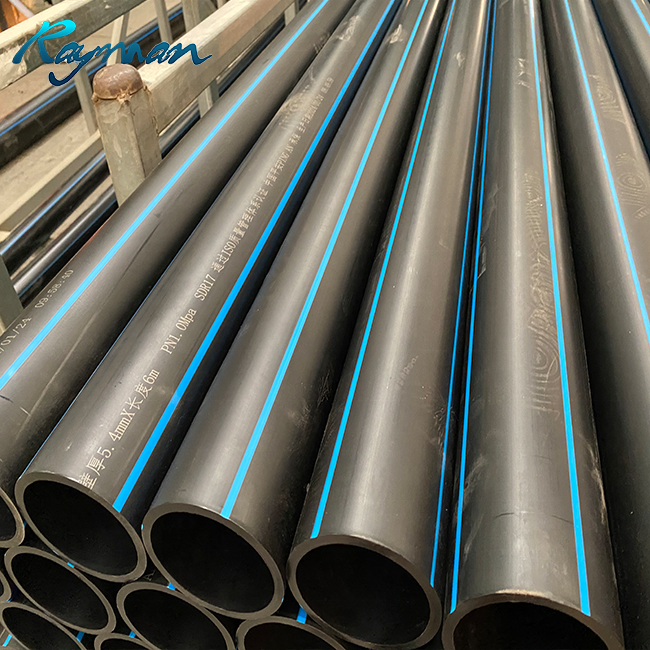

Rayman HDPE Pipe's Description

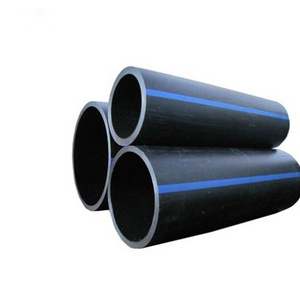

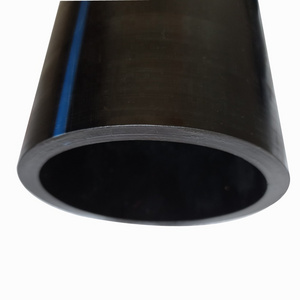

HDPE

(High-Density Polyethylene)

pipe

is a flexible plastic pipe used for the transfer of fluids and gases. It is commonly used to replace aging concrete or steel pipelines due to its durability and resistance to physical damage, corrosion, chemicals, and environmental hazards.

HDPE pipes offer numerous benefits, including cost-effectiveness, long life expectancy, and high resistance compared to other pipe materials such as clay, steel, ductile iron, or copper. The material used in HDPE pipes is a plastic resin made through the copolymerization of ethylene and a small amount of another hydrocarbon.

HDPE pipes are highly flexible, making them easy to install and handle during construction, and they are also elastic, providing an advantage during earthquakes or earth movements. Overall, HDPE pipes are a reliable and versatile option for various applications in the transfer of fluids and gases.

Rayman Pipes produces a diverse range of HDPE pipes that adhere to various national and international standards. Crafted using cutting-edge technology, these pipes are known for their lightweight, durability, longevity, low maintenance, and flexibility due to their natural elasticity. Renowned for their toughness stemming from high flexural and impact resistance, they can withstand significant internal and external pressures, including soil forces. Moreover, they exhibit resistance to chemicals, corrosive soil, acids, alkalis, and can be installed in challenging terrains without the need for additional coatings or cathodic protection.

Rayman's HDPE pipes are widely utilized in applications such as potable water supply, telecommunications, gas distribution, sewage and drainage systems, and sprinkler irrigation networks.

Rayman HDPE Pipe's Specification

|

item

|

HDPE PIPE best plumbing pipes

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

Rayman

|

|

Model Number

|

20mm - 800mm

|

|

Material

|

HDPE PE100

|

|

Specification

|

75MM

|

|

Length

|

11.8m 100 m or as request

|

|

Thickness

|

2.6mm 3.5mm 4.5mm 5.6mm 6.8mm 8.4mm

|

|

Standard

|

ISO

|

|

Processing Service

|

Cutting

|

|

Material

|

High Density Polyethylene

|

|

Color

|

Black

|

|

Application

|

Water Supply,Sewerage and Drainage,Mining

|

|

Diameter

|

DN20mm-1600mm

|

|

Advantage

|

Flexible,Durable,Chemical-resistant,Leak-Proof

|

|

Working pressure

|

0.6Mpa-2.0Mpa

|

|

Sample

|

Provide Samples

|

|

OEM

|

Acceped

|

|

Delivery Time

|

7-15 Days

|

|

Working Temperature

|

-50°C to 90°C

|

|

CONTACT INFORMATION

|

Tessa Chen

|

|

Email

|

raymanya@raymanpipe.com

|

|

Phone

|

+86 185 5382 5573

|

Rayman HDPE Pipe's Advantages

HDPE pipes are lightweight, facilitating rapid installation in various locations. They possess excellent impact and breakage resistance and have a high resilience against UV radiation, thanks to the UV stabilizers blended into the raw PE material. During installation, there's no need for protective measures like cathodic protection.

Connections can be made above ground, outside of the trench, offering convenience and flexibility. The pipes are also unresponsive to geological movements such as landslides and earthquakes, providing reliability under varying conditions.

Connections can be made above ground, outside of the trench, offering convenience and flexibility. The pipes are also unresponsive to geological movements such as landslides and earthquakes, providing reliability under varying conditions.

Thanks to their elasticity, HDPE pipes often require fewer fittings as they can bend to accommodate changes in direction. With a bending radius of 20 times their external diameter, they outperform other pipe types in this regard.

Additionally, the portability of PE pipe manufacturing facilities results in considerable transport cost savings for projects requiring large diameter pipes.

Overall, HDPE pipes offer the benefits of enhanced durability, simple installation, and efficient transport, with minimal risk of material loss.

Additionally, the portability of PE pipe manufacturing facilities results in considerable transport cost savings for projects requiring large diameter pipes.

Overall, HDPE pipes offer the benefits of enhanced durability, simple installation, and efficient transport, with minimal risk of material loss.

Rayman HDPE Pipe's Applications

1. Municipal Water Systems:

HDPE pipes are widely used for drinking water distribution and the mains supply in municipal water systems due to their leak-free joints and resistance to corrosion.

2. Sewerage Systems: They are also used in sewerage systems because of their chemical and crack resistance, ensuring a long service life even under harsh conditions.

2. Sewerage Systems: They are also used in sewerage systems because of their chemical and crack resistance, ensuring a long service life even under harsh conditions.

3. Agricultural Irrigation:

HDPE pipes are popular in agricultural irrigation systems since they are flexible, withstand various weather conditions and provide reliable performance for transporting water to fields.

4. Industrial Applications: In various industries, they are used to transport process water, wastewater, chemicals, and slurry because of their chemical resistance and non-reactivity.

4. Industrial Applications: In various industries, they are used to transport process water, wastewater, chemicals, and slurry because of their chemical resistance and non-reactivity.

5.

Marine and Dredging:

HDPE is used for marine applications including dredging pipes, floating pipes for dredged material, and marine pipelines due to its buoyancy and resistance to marine environments.

.

6. Gas Distribution: Gas distribution systems make use of HDPE pipes due to their toughness, flexibility, and reliability under high-pressure conditions.

6. Gas Distribution: Gas distribution systems make use of HDPE pipes due to their toughness, flexibility, and reliability under high-pressure conditions.

7. Mining:

HDPE pipes are used for the transportation of slurry in mining operations and also for subdrainage systems, vent stacks, and water lines within the mines.

8. Oil and Gas Exploration:

They are employed for the transfer of oil, gas, and even geothermal resources due to their high-pressure rating and temperature resistance.

9. Cable Protection: Telecommunication companies often use HDPE pipes to protect fiber optic cables because they are flexible and crush-resistant.

10. Fire Fighting Systems: Due to the material being non-corrosive and resistant to certain chemicals, HDPE pipes are used for fire fighting lines and outdoor fire hydrant systems.

9. Cable Protection: Telecommunication companies often use HDPE pipes to protect fiber optic cables because they are flexible and crush-resistant.

10. Fire Fighting Systems: Due to the material being non-corrosive and resistant to certain chemicals, HDPE pipes are used for fire fighting lines and outdoor fire hydrant systems.

11. Stormwater Systems:

Their ability to handle water with high levels of debris makes them suitable for stormwater drainage systems.

There are several methods for jointing HDPE pipes, including:

1. Butt Fusion: This is the most common method for joining HDPE pipes. It involves heating the ends of the pipes and then pressing them together to form a strong, leak-proof joint.

2. Electrofusion: This method involves using a special fitting with built-in heating elements to join HDPE pipes. The fitting is placed between the two pipes, and an electric current is passed through it to melt the pipes and create a secure joint.

3. Socket Fusion: This method involves using a special socket fusion tool to heat the ends of the pipes and then press them together to form a strong joint.

4. Mechanical Couplings: These are pre-fabricated fittings that can be used to join HDPE pipes without the need for heat. They are quick and easy to install, but may not be as strong as fusion joints.

5. Flanged Joints: Flanged joints are used for larger diameter HDPE pipes. The pipes are joined together using flanges and bolts to create a secure connection.

1. Butt Fusion: This is the most common method for joining HDPE pipes. It involves heating the ends of the pipes and then pressing them together to form a strong, leak-proof joint.

2. Electrofusion: This method involves using a special fitting with built-in heating elements to join HDPE pipes. The fitting is placed between the two pipes, and an electric current is passed through it to melt the pipes and create a secure joint.

3. Socket Fusion: This method involves using a special socket fusion tool to heat the ends of the pipes and then press them together to form a strong joint.

4. Mechanical Couplings: These are pre-fabricated fittings that can be used to join HDPE pipes without the need for heat. They are quick and easy to install, but may not be as strong as fusion joints.

5. Flanged Joints: Flanged joints are used for larger diameter HDPE pipes. The pipes are joined together using flanges and bolts to create a secure connection.

Rayman HDPE Pipe's Production

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches