- Product Details

- {{item.text}}

Quick Details

-

Power:

-

131kw

-

Weight:

-

4000kg

-

Dimension(L*W*H):

-

20*4*4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Material:

-

304 Stainless Steel

-

Production capacity:

-

120-700kg/h

-

Raw material:

-

Wheat flour, wheat bran

-

Fuel:

-

electricity/gas/diesel/LPG

-

Motor brand:

-

Siemens(or customized)

-

Inverter:

-

Taiwan Delta

-

Type:

-

Fully Automatic

-

Number/what's app:

-

+8618769779752

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO BV

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DINGRUN

-

Voltage:

-

380V/50HZ

-

Power:

-

131kw

-

Weight:

-

4000kg

-

Dimension(L*W*H):

-

20*4*4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Material:

-

304 Stainless Steel

-

Production capacity:

-

120-700kg/h

-

Raw material:

-

Wheat flour, wheat bran

-

Fuel:

-

electricity/gas/diesel/LPG

-

Motor brand:

-

Siemens(or customized)

-

Inverter:

-

Taiwan Delta

-

Type:

-

Fully Automatic

-

Number/what's app:

-

+8618769779752

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO BV

chicken nugget panko gold bread crumbs coating machine

Bread crumb is the wide spread use food increase supplementary material, mainly uses in the western-style food exploding the beefsteak, exploding the chicken leg and so on to fry in oil the supplementary material. Our company develops the development Panko bread crumbs extrusion machine changed the traditional bread crumb technique of production, invests from the lining to destroys the formation is the production-runs, the personnel are few, the excess stock might duplicate uses, does not have the waste material, to reduce the production cost, to raise the labor productivity. Main product acicular crumb, granular crumb etc.

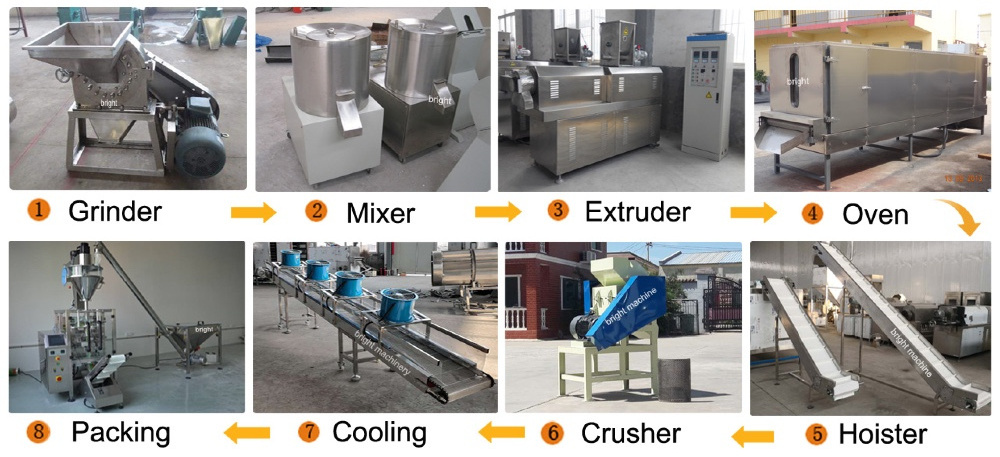

Flow chart:

Mixer-Screw conveyor-Twin screw extruder-Hoister-Humid crusher-Air conveyor-Multi-layer roasting oven-Air conveyor-packing.

Technical Parameter For Bread Crumbs Machines :

|

Model

|

InstalledPower

(KW)

|

Power Consumption

(kw)

|

Capacity

(kg/h)

|

Dimension

(m)

|

|

DSE65 processing line

|

74

|

52

|

100-150

|

17*1.2*2.2

|

|

DSE70 processing line

|

95

|

70

|

200-300

|

20*1.5*2.2

|

|

DSE85 processing line

|

139

|

102

|

300-500

|

28*3.5*4.3

|

The sample product:

Equipment list :

mixer→screw conveyor→twin screw extruder→air conveyor→crusher →hoister →oven→

cooling machine→packing machine

|

Name

|

Mixer

|

|

Usage

|

To mix the raw materials evenly, fast speed, no leakage.

|

|

Type

|

Vertical and horizontal type

|

|

Motor

|

3kw, 4kw, 7.5kw etc.

|

|

Capacity

|

20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc.

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Twin screw extruder

|

|

Usage

|

To extrude the raw materials and make them to the required shape and size of the pet food pellets by mould

|

|

Model

|

DSE65, 70, 75, 90, 95, 120, 135

|

|

Motor

|

22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

Screw materials 38CrMoAl

stainless steel, carbon steel

|

|

Name

|

Crusher machine

|

|

Usage

|

crush the material into a needle-like

|

|

Type

|

PSJ

|

|

Motor

|

3.5kw

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Dryer (oven)

|

|

Usage

|

the expanded food go through the "s" passage, to be dried to increase the self life.

|

|

Type

|

electrical, steam, gas fired, diesel fired heating type

|

|

Model

|

KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Packaging machine

|

|

Usage

|

To pack the pet food with required weight

|

|

Type

|

Automatic

|

|

Flowing Process

|

Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing

|

|

Weight range

|

1-5kg/bag, 5-25kg/bag, 25-50kg/bag

|

|

Material

|

stainless steel, carbon steel

|

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case (based on the customers’

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.