- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

40 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FAYGO

-

Voltage:

-

380v 50hz 3phase (customized)

-

Dimension(L*W*H):

-

26m*2.5m*1.8m

-

Weight:

-

5 KG

-

Name:

-

WPC Wood plastic composite

-

Other name:

-

door production line

-

inverter:

-

ABB

-

PLC:

-

Siemens

-

Electricial parts:

-

Siemens

-

Final product:

-

WPC profile

-

Brand:

-

FAygo extruder

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

40 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FAYGO

-

Voltage:

-

380v 50hz 3phase (customized)

-

Dimension(L*W*H):

-

26m*2.5m*1.8m

-

Weight:

-

5 KG

-

Name:

-

WPC Wood plastic composite

-

Other name:

-

door production line

-

inverter:

-

ABB

-

PLC:

-

Siemens

-

Electricial parts:

-

Siemens

-

Final product:

-

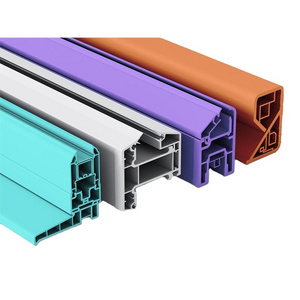

WPC profile

-

Brand:

-

FAygo extruder

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

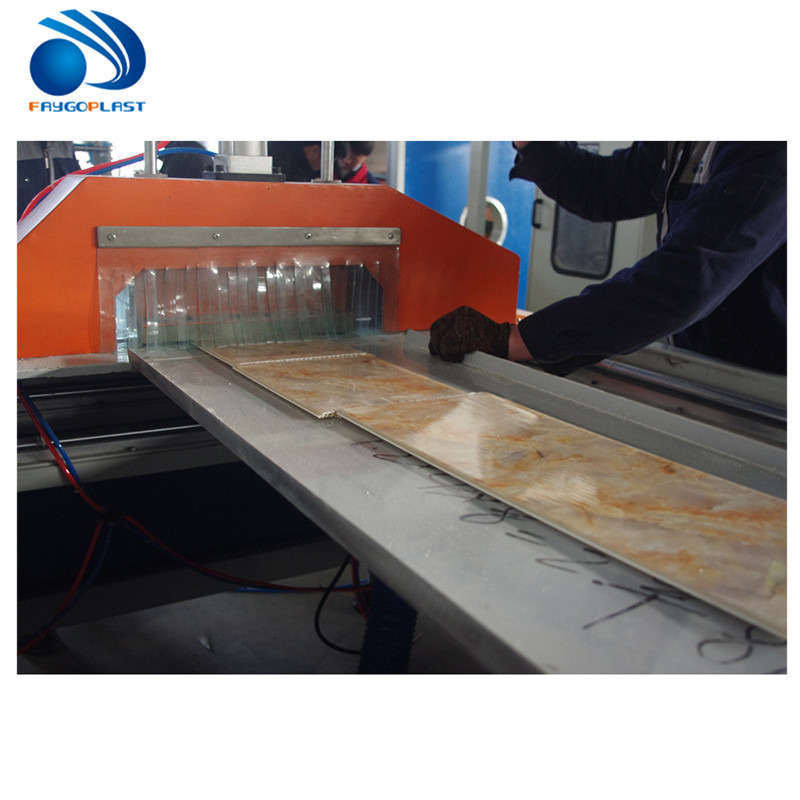

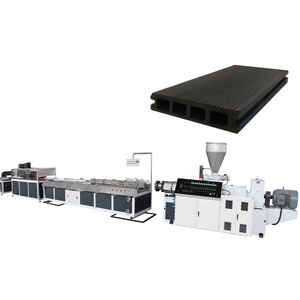

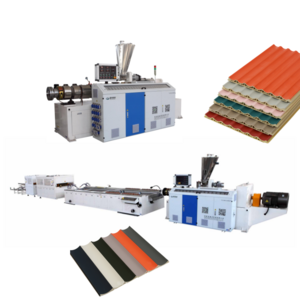

WPC Wood plastic composite WPC machine manufacturer / WPC production line

The WPC door machine is used to produce the wpc door,(door width: 600mm, 750mm, 800mm, 900mm, 1000mm, thickness: 25-40mm, hollow or solid)

plastic can be PE or PP or PVC.

A whole extrusion line includes the following units:

1, material screw feeder,

2, conical twin-screw extruder,

3, calibration table,

4, haul-off and cutter,

5, stacker.

Auxiliary machine

1, material mixer

2, matrials compounding machine

3, door surface processing mahcine---sanding, embossing, laminating, hot stamping, carving

4, crusher and miller for reusing the water wpc profiles

Properties

1),The screws and barrel are made of 38CrMoAlA, with nitriding processing.

2),reducer: hard gear teeth surface ,

3),main motor and forced feeder: use inverter for speed adjustment,

4),height of calibration table can be adjusted easily from control panel.

5), cutter with alloy saw and dust collector.

6), SIEMENS electric parts

7), free production formula technology for cooperation

8), turn-key project cooperation.

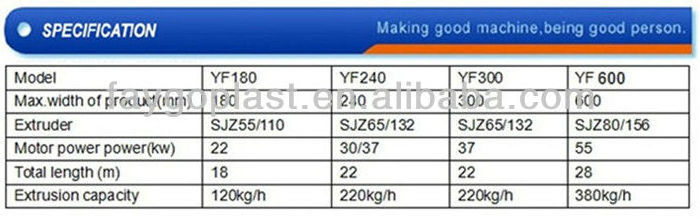

Available extruder models

|

|

|

|

|

If you want get more information, please contact us, thanks! Our company is near Shanghai ,about 150km . |