- Product Details

- {{item.text}}

Quick Details

-

Size:

-

Customer Size Accepted

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SME

-

Model Number:

-

OEM, as the client

-

Size:

-

Customer Size Accepted

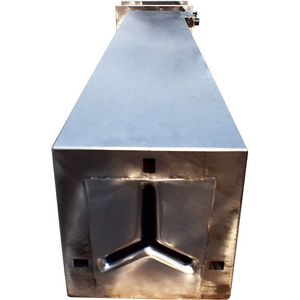

FRP

The main material of our mold is high-strength FRP (Fiberglass reinforce plastic). High compression strength and excellent convertibility make us easier to create any complicated and irregular moulds and shorten the production time

Specifications

|

Product: |

FRP thermoforming mold |

|

Min. Order: |

1 Set |

|

Transportation: |

by Sea |

|

Product Material: |

Fiberglass reinforce plastic |

|

Shaping Mode: |

Vacuum\pouring\injection |

|

Export Markets: |

North America, South America, Eastern Europe, Southeast Asia, Western Europe, Mid East |

|

Payment: |

T\T,L/C |

|

Size |

Customized |

Our advantage

1. Comprehensive design level : 10-years experience in vacuum forming machine and forming molds manufacturing, so we can make product design more reasonable, more beautiful, more comfortable;

2 . High efficient : professional manufacture, team spirit, high efficient let you capture market more guarantee; the shortest delivery time for spa mold is 30days.

3 . Exquisite in workman ship : professional technology, strict quality control, stop mold appear defect like rough, bubble, deformation, flaw completely.

4. Concise program : to lower technician press mostly, all the design we try our best to do it for you.

5. Guarantee maintain : 2 years free maintain for local area client, maintain technology can be offer free to other area;

Process

1st. step

Receive the sample or drawing from client, or the client give us the requirement.

2nd. step

Make a sample by 3D printing;

3rd. step

Our engineer dept. will design the mold by 3D or 2D drawing, and offer UG,Pro/E,solidworks, CAD and CAX...etc. drawing for client to check.

4th. step

After the client check the drawing, we start to process the moulds.

5th. step

Test the moulds, and send the sample to our client to check it.Or invite client to our factory to check.Because we the machine manufactory, we have the thermoforming machine to test the moulds anytime.

6th. step

If the client think the mould is OK, we send the mould to them. If not, we modify the mould meet the client's requirement.

7th. step

Use the wooden case to package the mould;

Our Machines

Minimun Order Quantity:1 set

Delivery time:15 ~ 35business days after deposit;

Payment terms: T/T 50% deposit before production, 50% balance before delivery date;