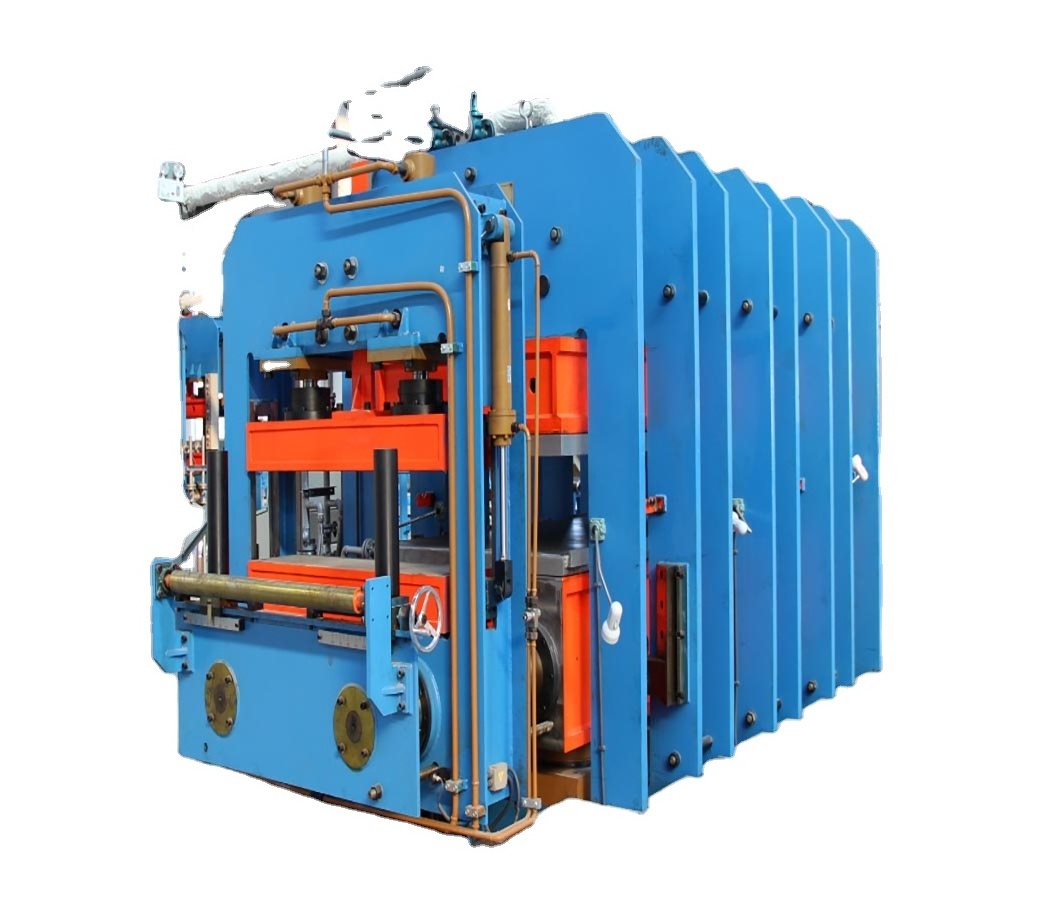

B:Heating pipes: Stainless steel ,long using life, material is SUS304

C:Plunger: Vanadium and titanium Alloy Chilled Cast Iron, High hardness (68~72HS )and good abrasion , resistance, can not easy broke the seals

D:Hydraulic cylinder: Nodular cast iron, the material is QT-500, hardness 68~72 HS, using the annealing treatment, and flaw detection process choose the best one.

E:The heating plate :35# steel

F: Thermal baffle: Silicon 3 Calcium plate, not easy broke seals

G: Valve: Cartridge valve, not easy broken and no need maintain brand from Huade (China-Germany joint venture )

H:Hydraulic pump: Brand from YUCI YUKEN HYDRAULICS Co., LTD Japan brand

I: Low-voltage apparatus: The brand from Schneider or Mitsubish