- Product Details

- {{item.text}}

Quick Details

-

Condition:

-

new

-

Applicable Industries:

-

Demolition of buildings, Excavator construction, Shear of scrap steel

-

Weight:

-

380

-

Suitable Excavator(ton):

-

10-40t

-

Width:

-

/

-

Height:

-

/

-

Opening:

-

/

-

Core Components:

-

Wear resistant alloy cutting edge

-

Color:

-

Black

-

Name:

-

Demolition Scrap

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

dpair

-

Model Number:

-

DSH25

-

Condition:

-

new

-

Applicable Industries:

-

Demolition of buildings, Excavator construction, Shear of scrap steel

-

Weight:

-

380

-

Suitable Excavator(ton):

-

10-40t

-

Width:

-

/

-

Height:

-

/

-

Opening:

-

/

-

Core Components:

-

Wear resistant alloy cutting edge

-

Color:

-

Black

-

Name:

-

Demolition Scrap

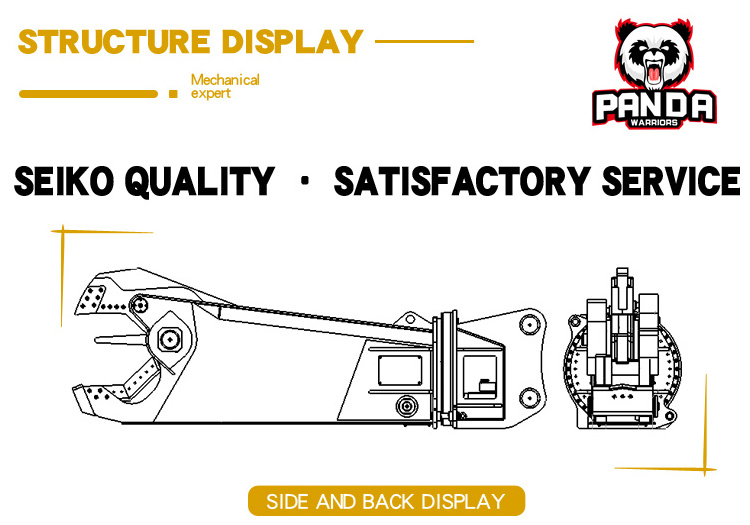

Products Description

Scrap Shear

We offer a full range of high performance steel shears for scrap processing & dismantling applications. A heavy duty hydraulic rotation comes as standard throughout the range. HSS shears can also be supplied without rotation if preferred and all models can be adapted to fit the excavators stick or boom as appropriate.

The quality cutting blades on the shear are fully indexable and replaceable. Manufactured to exacting specifications for a long service life and positive shearing action, they will stand up to the toughest site duties. A wear blade is installed in the lower jaw which prevents excess jaw straining and can be replaced and maintained to ensure trouble-free cutting on light materials.

The main pivot pin is equipped with a simple adjuster system which permits adjustment of the top jaw to compensate for any wear which may occur during the shears operating life.

All grease points are readily accessible and the powerful reverse mounted hydraulic cylinder is fully protected within the shear super-structure. A regenerative ‘speed’ valve ensures that cycle times are as short as possible.

There are 12 models available from 450kg up to 20 tonnes, for excavators from 3 – 280 tonnes.

Scrap Shears can be installed on excavators of various brands and models, and only one operator of the excavator is required to operate it, which truly realizes the versatility and economy of the product.

Scrap Shear are installed on excavators and are widely used for dismantling scrap cars, dismantling factory steel structures, ship breaking, cutting steel bars, steel, tanks, pipes and other scrap steel.

Dpair Scrap Shear wear resistance steel has high strength, light weight and large shear force.

The design of hooking angle can make it easier to hook the material "straight into the sharp knife" and cut off the structural steel. It is suitable for the disassembly of heavy vehicles, metal ships in steel mills, bridge decomposition and other steel structure facilities.

|

Model

|

Unit

|

DSH25

|

DSH130R

|

DSH180R

|

DSH310R

|

DSH410R

|

DSH550R

|

|

Suitable Carrier

|

T

|

4-5

|

13-17

|

18-27

|

28-37

|

38-50

|

50-60

|

|

Jaw opening (A)

|

mm

|

195

|

375

|

445

|

565

|

670

|

760

|

|

Jaw depth(B)

|

mm

|

200

|

395

|

525

|

630

|

720

|

780

|

|

Length(C)

|

mm

|

1350

|

2100

|

2700

|

3300

|

3700

|

3950

|

|

Tool Weight

|

Kg

|

380

|

1220

|

2100

|

3300

|

4700

|

5750

|

|

Speed valve

|

N

|

Y

|

Y

|

Y

|

Y

|

Y

|

Y

|

|

Interchangeable spare parts

|

Y

|

Y

|

Y

|

Y

|

Y

|

Y

|

Y

|

PRODUCT FEATURES

Jaw protection system - weld on upper & lower jaw protection. Reduces maintenance and need for build-up on upper jaw. The replaceable lower jaw protection plate eliminates damage to main lower jaw and reduces down-time on site.

Bolt-on piercing tip & blades - Reduces stress and wear on the upper jaw. Every blade can be turned several times on different sides and are easy to replace.

Innovative speed valve - Reduces cycle times, regenerates power when needed and protects the shear. Eliminates internal oil pressure peaks.

Dual upper jaw guides - Assures perfect alignment every time. Guides on either side of upper jaw increase cutting power, efficiency and production.

Fixed jaw design - Increased cut performance, the cut materials can exit easily.

360° rotation - Anti-cavitation valve and continuous rotation of 360°. Allows perfect positioning of the shears.

Fully protected, high power cylinder with bolt on access panels. Allows easy servicing.

Product discount sales activities

We have a history of 8 years from the generation of Hydraulic Demolition Shears and have many customers in China and Asia. In order to expand our worldwide sales business, we are now holding product discount promotion activities,

now ordering can enjoy 20% discount.

PUTTING YOUR NEEDS FIRST

No matter the industry in which you work, we know that your needs are unique. Whether you run a small family business or are a large nationwide company, we make it our mission to understand your requirements and add value to your business. By choosing to only work with the best attachment manufacturers in the world, we can provide you with a range of quality and innovative products that will meet your demands. We underst and that the customer experience doesn’t end when you walk out the door and our team will continue to look after you with regular servicing of your equipment to avoid any operational downtime. Every sale, hire or repair we undertake is backed by many years of combined industry experience and dedication to providing good old-fashioned family service.

We are committed to:

• Supplying the highest quality equipment and maintenance services

• Understanding your needs to provide knowledgeable and practical technical advice

• Keeping costs down without compromising your requirements

• Carrying out full quality control checks and testing of equipment

• Attending to breakdown call outs promptly and efficiently

• Maintaining an honest, reliable and transparent approach across everything we do

Real product application

In the Chinese market, our hydraulic demolition scissors account for 65% of the market share. The following pictures are from the customer's field construction scene. We can provide customers with the most suitable equipment according to the customer's excavator type and project situation, so as to save the most money for customers.

Product packaging

Manufacturing Technique

Certifications

Hot Searches