- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Multi-function for tunnel kiln dri

-

Material:

-

Stainless steel

-

Application:

-

Bread bakery machine

-

Feature:

-

High efficiency of tunnel kiln dri

-

MOQ:

-

1 set

-

Tray size:

-

600*400mm

-

Package:

-

Wooden case

-

Color:

-

Sliver

-

Energy:

-

Gas/electric

-

Keyword:

-

small tunnel kiln

-

Usage:

-

BAKING

-

Power Source:

-

gas/electric

-

Certification:

-

CE,ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Type:

-

Deck Baking Oven

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Multi-function for tunnel kiln dri

-

Material:

-

Stainless steel

-

Application:

-

Bread bakery machine

-

Feature:

-

High efficiency of tunnel kiln dri

-

MOQ:

-

1 set

-

Tray size:

-

600*400mm

-

Package:

-

Wooden case

-

Color:

-

Sliver

-

Energy:

-

Gas/electric

-

Keyword:

-

small tunnel kiln

-

Usage:

-

BAKING

-

Power Source:

-

gas/electric

-

Certification:

-

CE,ISO

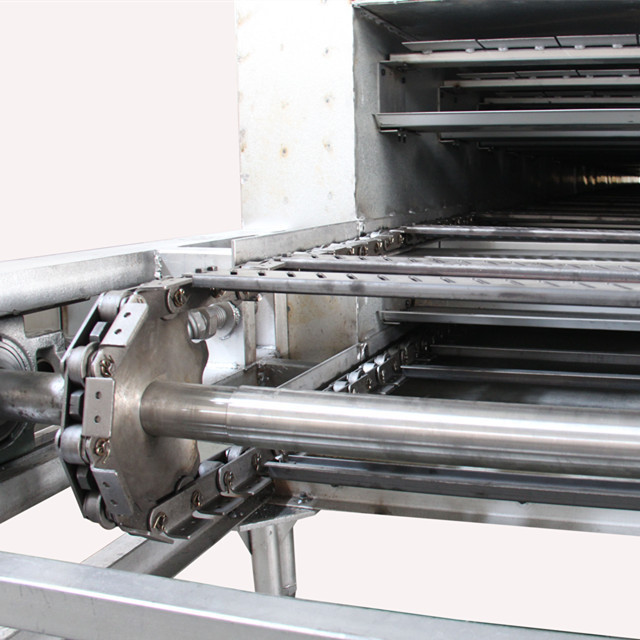

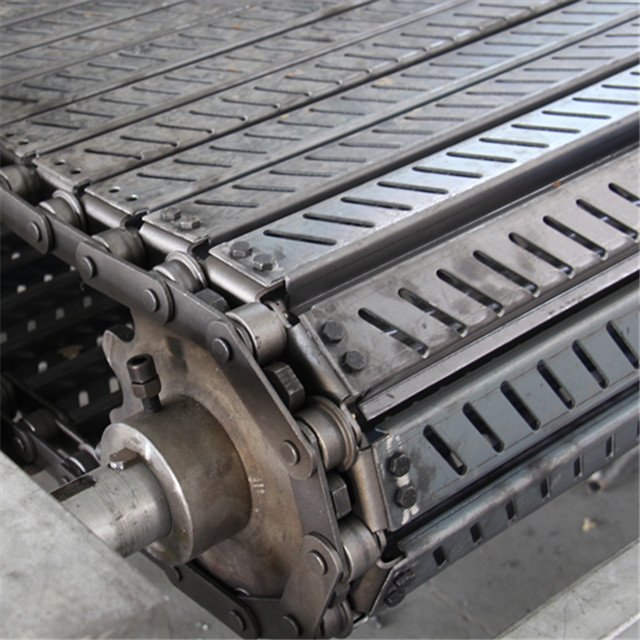

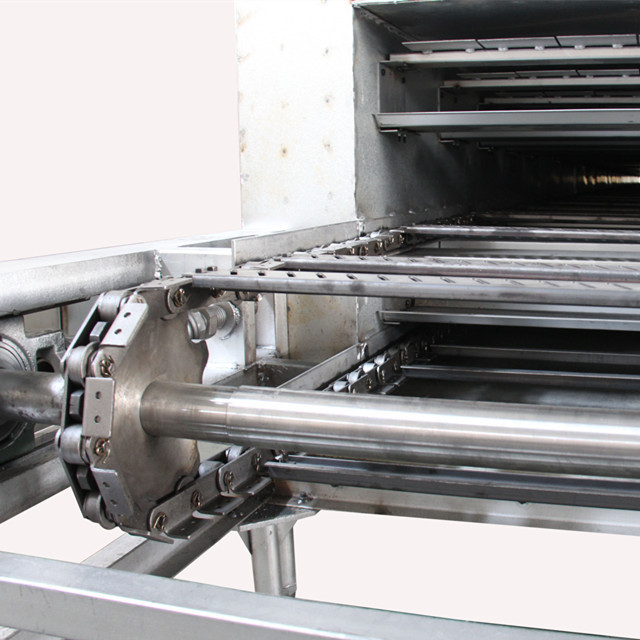

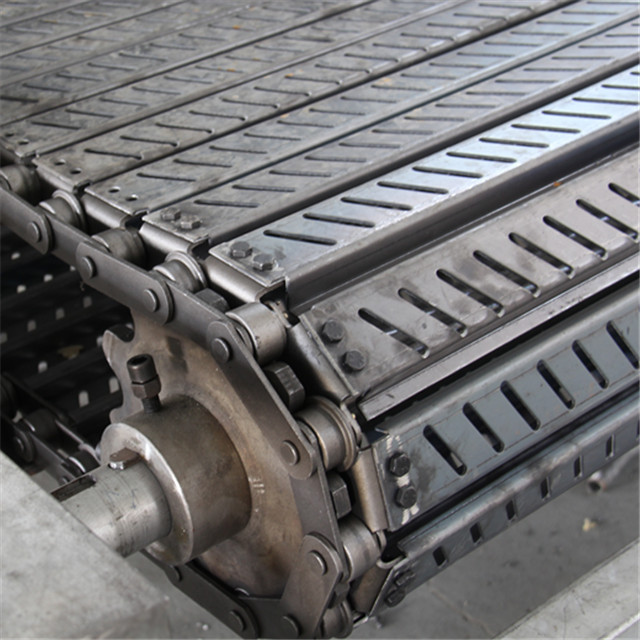

Industrial direct cart burner rotary tunnel kiln

A. Detailed Pictures

B. Baking range

Bakery products such as bread, cakes, moon cakes, biscuits, toast, and French sticks.

C. Advantages

1. Flexible independent control of the top and bottom.

Each heater has a separate electric furnace wire and a burner to heat the top and bottom, respectively.

2. A variety of heating methods.

Direct gas furnace, direct convection gas furnace, direct electric oven, indirect radiant furnace, mixing furnace.

3. Reasonable structure.

The tunnel furnace features an excellent insulation enclosure, conveyor belt and drive, observation window and exhaust fan.

4. Simple operation, convenient regulation.

The control panel clearly displays information such as baking time and temperature.

5. Fully burnt, safety protection system.

All the gas is filtered before entering the oven, and the forced combustion method and the air gas ratio control complete the mixed combustion mode to ensure the full combustion of the fire tube combustion system.

6. Customized services to meet demand.

D. Techincal Parameters

|

M odel |

Power source |

I nner hall width ( mm ) |

O utside W idth ( mm ) |

P ower ( kcal/m ) |

N ormal C onsumption ( kcal/m ) |

T ray S ize ( mm ) |

|

MY01 |

electric |

1400 |

2050 |

12000 |

6000 |

600*400 |

|

MY0 2 |

gas |

1400 |

2200 |

12000 |

6000 |

600*400 |

|

MY0 3 |

electric |

2000 |

2650 |

17200 |

8600 |

600*40 0 |

|

MY0 4 |

gas |

2000 |

2800 |

17200 |

8600 |

600*40 0 |

|

MY0 5 |

electric |

2220 |

2870 |

19100 |

9550 |

630*507 |

|

MY0 6 |

gas |

2220 |

3020 |

19100 |

9550 |

630*507 |

|

MY0 7 |

electric |

2600 |

3250 |

22400 |

11200 |

600*400 |

|

MY 08 |

gas |

2600 |

3400 |

22400 |

11200 |

600*400 |

|

MY0 9 |

electric |

3200 |

3850 |

27500 |

13750 |

600*400 |

|

MY1 0 |

gas |

3200 |

4000 |

27500 |

13750 |

600*400 |

|

MY 11 |

electric |

3800 |

4450 |

32400 |

16200 |

600*400 |

|

MY12 |

gas |

3800 |

4600 |

32400 |

16200 |

600*400 |

Training

1.We will supply with the machine operation manual in English version for installing and operation.

2.We will make training video for client’s reference.

3.Customer can come to our factory for free training.

Warranty and After sales service

1.Our warranty is within 12 months from the date when client receive the material.

2.We supply after sales service for 24 hours, 7 days per week. Customer can contact us any time.

3.When some problems can’t be solved by customers, our engineer can go to door to support.