- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

All types

-

Particle:

-

1.2

-

Product name:

-

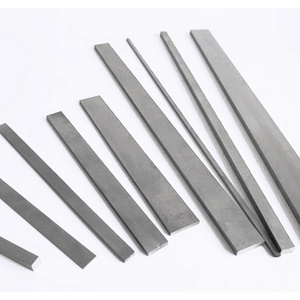

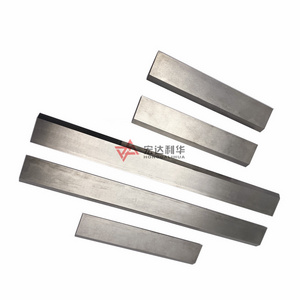

Tungsten Carbide Strip

-

Application:

-

Lathe Cutter

-

Grade:

-

YG6/YG8/ YG6X /YL10.2

-

Size:

-

Customer Required

-

Hardness:

-

HRA82-HRA92.9

-

Packaging:

-

Neutral Packaging

-

Feature:

-

Widely Used

-

Delivery:

-

10-20 Days

Quick Details

-

Alloy Specification:

-

YG8/YG15

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

zg

-

Model Number:

-

All types

-

Particle:

-

1.2

-

Product name:

-

Tungsten Carbide Strip

-

Application:

-

Lathe Cutter

-

Grade:

-

YG6/YG8/ YG6X /YL10.2

-

Size:

-

Customer Required

-

Hardness:

-

HRA82-HRA92.9

-

Packaging:

-

Neutral Packaging

-

Feature:

-

Widely Used

-

Delivery:

-

10-20 Days

|

Product Name

|

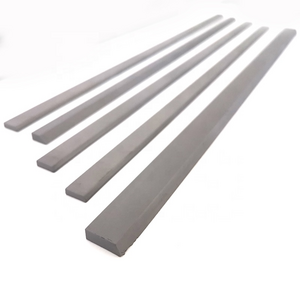

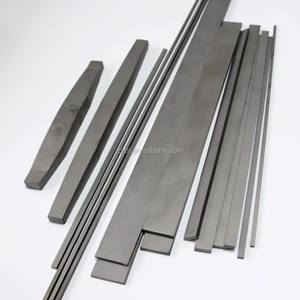

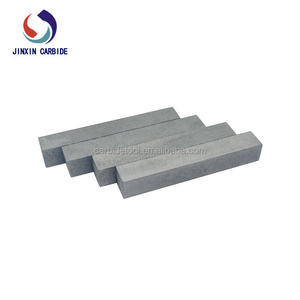

Tungsten carbide plate/strip

|

|

|

|

|||

|

Material

|

100% tungsten carbide raw material

|

|

|

|

|||

|

Grain size

|

0.4-1.6μm

|

|

|

|

|||

|

Grade

|

YG8X,YG11,YG6X,YL10.2 ,YG15,YG20,other grade can be offered by customers' request

|

|

|

|

|||

|

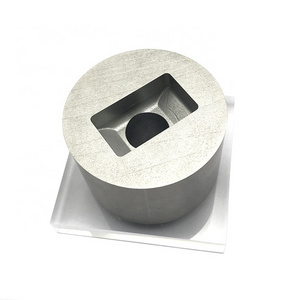

Size

|

Can accept any size customization.Such as L165 xW6 xT3,L100*W100*5 etc.

|

|

|

|

|||

|

Surface treatment

|

blank or grinding

|

|

|

|

|||

|

Standard length

|

100/165/330mm,other length also can be offered

|

|

|

|

|||

|

Application

|

Tungsten carbide strip is used for woodworking cast iron cutting tool. It can be used in many field such as woodworking, machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar,etc.

|

|

|

|

|||

|

Grade

|

Density(g/cm³)

|

Hardness (HRA)

|

TR.S (Mpa)

|

Performance&application recommended

|

|

YG6A

|

14.85

|

92.5

|

2000

|

Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,wear-resistant parts etc.

|

|

YG8

|

14.7

|

89.8

|

2800

|

High bending strength,wear resistance lower than YG6A suitable for manufacturing forming cutter,wear-resistant parts etc.

|

|

YG11

|

14.4

|

88.5

|

2900

|

|

|

YG15

|

14.0

|

87

|

3000

|

Suitable for manufacturing punching dies,wear-resistant parts etc.

|

|

YG20

|

13.5

|

85.5

|

2800

|

High bending strength,suitable for manufacturing progressive dies and other punching dies.

|

|

YG13X

|

14.2

|

90

|

3200

|

|

|

YS2T

|

14.25

|

92

|

2500

|

Fine grain alloy,with high wear resistance,bending strength,bonding resistance and thermal strength.It is suitable for machining refractory alloys,stainless steel,high manganese steel etc.

|

Q1: Are you manufacturer or trading company ? We are manufacturer of tungsten carbide products.

Q2: Where is your factory located?

We are located in ZhuZhou city, Hunan province where is 1 hours-driving from Changsha airport.

Q3: Are the products High Quality?

Yes. Raw material will be tested before bulk production, and we will check the phys-ical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What’s your delivery time ?

Generally it is 3~5 days if the goods are in stock; or it is 7-25 days if the goods are not in stock, depending on order quantity.

Q5: Do you provide samples?

Generally we don't provide free samples. But we can deduct sample cost from your bulk orders.

Q6: How to place an order of tungsten carbide products?

1. Fill your Order List in our online Inquiry System.(Also you can directly contact our salesperson by E-mail / WeChat /Whatsup)2. within 12-hours feedback when receiving your message.

Q2: Where is your factory located?

We are located in ZhuZhou city, Hunan province where is 1 hours-driving from Changsha airport.

Q3: Are the products High Quality?

Yes. Raw material will be tested before bulk production, and we will check the phys-ical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What’s your delivery time ?

Generally it is 3~5 days if the goods are in stock; or it is 7-25 days if the goods are not in stock, depending on order quantity.

Q5: Do you provide samples?

Generally we don't provide free samples. But we can deduct sample cost from your bulk orders.

Q6: How to place an order of tungsten carbide products?

1. Fill your Order List in our online Inquiry System.(Also you can directly contact our salesperson by E-mail / WeChat /Whatsup)2. within 12-hours feedback when receiving your message.

Hot Searches