- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Online support, Free spare parts, Video technical support, Engineers available to service machinery overseas

-

Name:

-

metal siding roll forming machine

-

Raw material:

-

Aluminium/Zinc

-

Usage:

-

Steel Construction

-

Shaft material:

-

High Grade No.45 Forged

-

Roller material:

-

45#steel Chrome Plated

-

Control system:

-

Touch Screen

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main fram:

-

300 H steel

-

Product name:

-

metal siding roll forming machine

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Online support, Free spare parts, Video technical support, Engineers available to service machinery overseas

-

Name:

-

metal siding roll forming machine

-

Raw material:

-

Aluminium/Zinc

-

Usage:

-

Steel Construction

-

Shaft material:

-

High Grade No.45 Forged

-

Roller material:

-

45#steel Chrome Plated

-

Control system:

-

Touch Screen

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main fram:

-

300 H steel

-

Product name:

-

metal siding roll forming machine

-

Certification:

-

CE/ISO9001

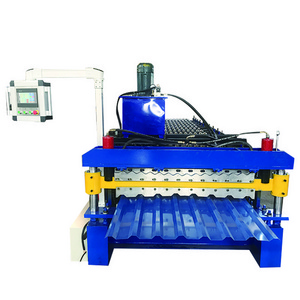

PLC control aluminum coil metal sheet siding roll forming machine for sale

1.Panel drawing

2. Technique parameters

(1) Processing material: aluzinc/galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.8mm

(3) Effective width: 246mm

(4) Feeding width: 315mm

(5) Main motor power: 3 kw

(6) Pump power: 3 kw

(7) Shaft diameter: 65 mm

(8) Forming steps: 22 steps

(9) Roller material: 45 # forged steel, with hard chrome plating

(10) Main frame: Square tube machine frame

(11) Medium plate thickness: The whole middle plate

(12) Control systerm : Delta PLC computer control with touch screen

3.Machine pictures for your reference.

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will mpaint the coil on the roller and shaft, in case the roller and shast got corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts, and fix all the parts into container by the steel wire rope, and ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container