The main purpose of the paper pulping stage is to treat the waste paper into evenly mixed paper pulp without impurities. First, we

need to mix the waste paper with water, stir and smash it, and screen out the impurities. Then we should further homogenize the

pulp. During this process, chemical reagents such as thickeners and pigments can be added.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/420V/440V

-

Power:

-

57 kw

-

Weight:

-

7600 kg

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

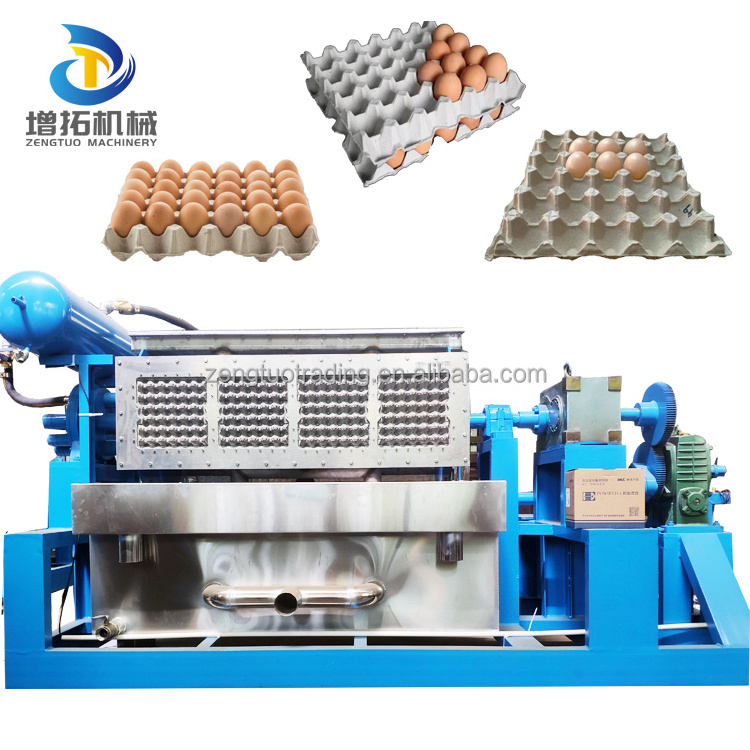

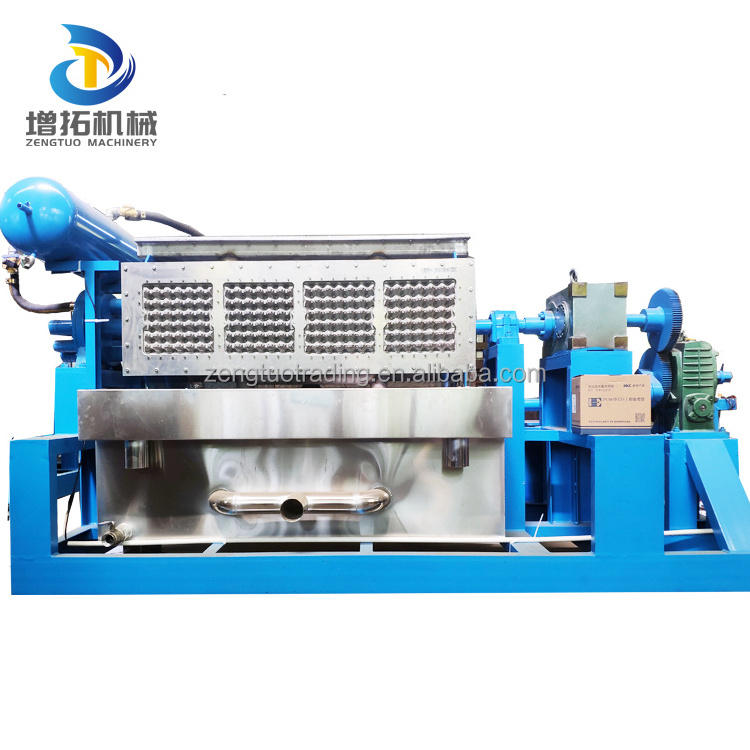

Egg Tray Machine without Dryer

-

Capacity:

-

3000 Pcs/h

-

Moulds Quantity:

-

16 forming molds+ 4 transferring molds

-

Moulds Materials:

-

Plastic / Aluminum

-

Drying Method:

-

Natural Drying in the sun

-

Raw material:

-

Waste Paper

-

Finished Products:

-

Egg Tray Egg Carton

-

After-sales Service Provided:

-

Online Support, Commissioning, Training, Video Support

-

WhatsApp & WeChat:

-

0086 18712958030

Quick Details

-

Production Capacity:

-

3000 pcs/hour

-

Place of Origin:

-

HEB

-

Brand Name:

-

Zengtuo/ZT

-

Voltage:

-

220V/380V/415V/420V/440V

-

Power:

-

57 kw

-

Weight:

-

7600 kg

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Egg Tray Machine without Dryer

-

Capacity:

-

3000 Pcs/h

-

Moulds Quantity:

-

16 forming molds+ 4 transferring molds

-

Moulds Materials:

-

Plastic / Aluminum

-

Drying Method:

-

Natural Drying in the sun

-

Raw material:

-

Waste Paper

-

Finished Products:

-

Egg Tray Egg Carton

-

After-sales Service Provided:

-

Online Support, Commissioning, Training, Video Support

-

WhatsApp & WeChat:

-

0086 18712958030

Brief Introduction

Product Paramenters

|

|

||

|

Capacity

|

3000 pcs/hour

|

|

|

Molds

|

16 forming molds + 4 transferring molds

|

|

|

Mold Materials

|

Plastic, Aluminum, Copper. The molds can be customized as actual egg tray samples.

|

|

|

Remark

|

the molds can be customized as actrual egg tray samples

|

|

|

Production Line

|

Pulping System + Molding System + Natural Drying Equipment (OPTIONAL)

|

|

|

Final Egg Tray Weight

|

Calculate with 80g final 30 egg tray weight, but the weight can be adjusted as requested.

|

|

|

Paper Consumption

|

212 kg/h

|

|

|

Water Consumption

|

636 kg/h, Water is recycling used in production

|

|

|

Electricity Consumption

|

Total power is 59 kw, Actual electricity consumption is only 70%, about 40 kw/h.

|

|

|

Labor/worker

|

3-5 persons/shift

(pulping system need 1 person, machine operating need 1 person, collect tray and packing need 2 persons)

|

|

|

Workshop

|

Length and width 10×10m,height≥4.5m. Can be adjusted according to customer existing plant, the drying space suggest 500㎡ above.

|

|

|

Installation

|

The buyer shall be responsible for all construction and installation. The seller shall send 1 engineer to guide the installation, commissioning and training online. The buyer should pay subsidy ( USD100/person/day).

|

|

|

Warranty

|

1 year for the machine, except spare parts

|

|

|

Containers

|

1x20GP

|

|

|

Delivery

|

20 working days, if customize aluminum molds need 40 days.

|

|

Egg Tray Process

Step 1. Paper Pulping System

Hydraulic Pulper

Put waste paper and water into the hydraulic pulper, after mixing get the paper pulp.

Agitator/Mixer/Homogenizer

Use the Agitator mix the paper pulp again and again, get better quality paper pulp.

Pulp Pump

The pulp pump will supply the ready paper pulp to the egg tray forming machine directly.

Step 2. Egg Tray Molding System

Egg tray molding is the most important step in the manufacturing process. The prepared paper pulp is tightly attached to the mold

in the egg tray making machine under the assistance of a vacuum pump. After the desired shape is formed, the wet egg tray is

separated from the mold and transported to the next step by frames.

in the egg tray making machine under the assistance of a vacuum pump. After the desired shape is formed, the wet egg tray is

separated from the mold and transported to the next step by frames.

Vacuum Pump

The vacuum pump will absorb the extra water from the wet egg tray, and take into the sewage pool.

Air Compressor

The air compressor work with the molding machine and vacuum system to make and transfer the egg trays.

Step 3. Egg Tray Natural Drying System

The molded egg tray is semi-dry and contains about 30% moisture. For enhancing its firmness and stability, we need to dry the excess water. Generally, we can choose natural drying (drying under the sun directly)

Pallets

Hold the wet egg tray directly.

Frames

Hold the frames with wet egg trays

Carts

Move the frames with egg trays.

Molds&Finished Products

Packing & Delivery

1. Outside: Standard export package

2. Inner: Stretch film

3. Container: FCL

Hot Searches