- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mascot

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

700*500*1220mm/ 950*750*1500mm

-

Power (kW):

-

4

-

Weight (T):

-

3

-

Product name:

-

Bottle Shredder Machines, Coconut Husk Shredder Machines For Sale

-

Application:

-

Recycle Waste Plastic

-

After-sales Service Provided:

-

Online Support

-

Raw material:

-

PET. PE. PVC

-

Final product:

-

Small Plastic Scraps

-

Color:

-

Customized Color

-

Advantage:

-

Easy Opperation

-

After Warranty Service:

-

Online Support Field Maintenance

-

Certification:

-

ISO9001

-

Equipment:

-

Shredder Used Plastic

Quick Details

-

Max.Production Capacity (kg/h):

-

25t/h

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

2000 - 25000 kg/h

-

Brand Name:

-

Mascot

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

700*500*1220mm/ 950*750*1500mm

-

Power (kW):

-

4

-

Weight (T):

-

3

-

Product name:

-

Bottle Shredder Machines, Coconut Husk Shredder Machines For Sale

-

Application:

-

Recycle Waste Plastic

-

After-sales Service Provided:

-

Online Support

-

Raw material:

-

PET. PE. PVC

-

Final product:

-

Small Plastic Scraps

-

Color:

-

Customized Color

-

Advantage:

-

Easy Opperation

-

After Warranty Service:

-

Online Support Field Maintenance

-

Certification:

-

ISO9001

-

Equipment:

-

Shredder Used Plastic

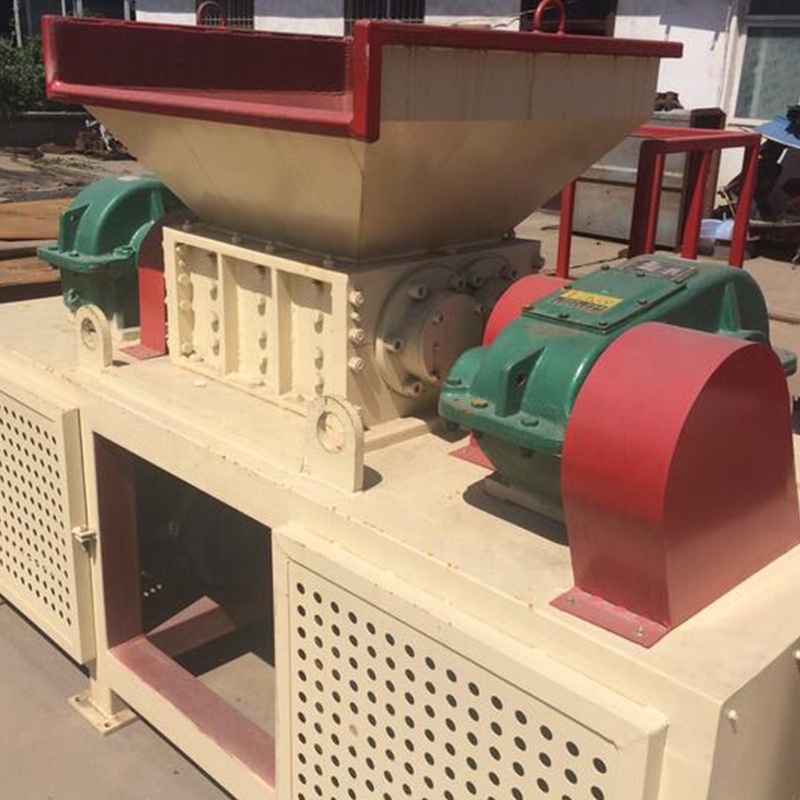

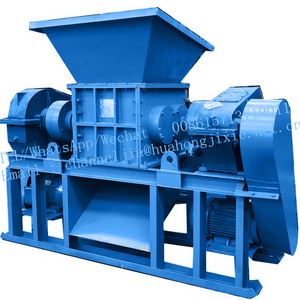

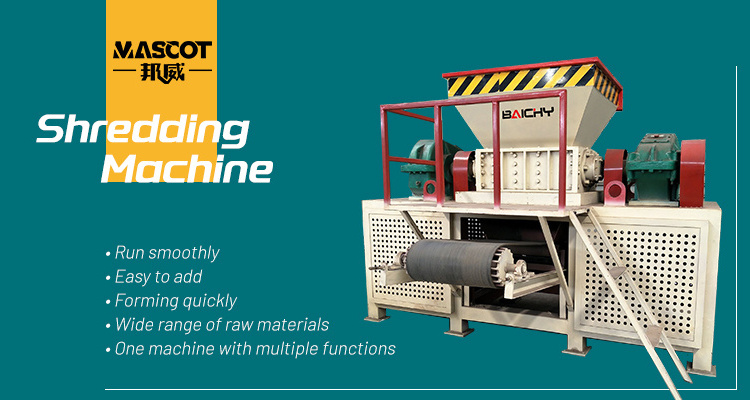

Tyre Recycling Plant / Used Tire Shredder Machine for Sale/Tire Shredding Machine

The shredding machine also called a shear-type shredding machine, by cutting ,tearing, and extrusion of materials to achieve a smaller size. A shredding machine is widely used for shredding big sizes of hollow containers(Clinker bucket, etc) and a variety of metal mixture scraps, etc. Shredding machine adopts a unique rotary shaft structure and rotary type blades at low speed and high torque production process, it does not appear wrapped around the shaft, or stuck equipment phenomenon, resulting in improved production efficiency. The thickness and number of blades can be replaced according to different materials.

The two-shaft shredder is a low speed and high torque industrial, thus saving energy. This dual shearing shredder does not have a screen unit. After material is fed into the hopper, material is handled using two counter rotating blades, then directly discharged. Although the output particle size is random, the two shaft shredder features a faster shredding speed and a higher throughput than other shredders. Double shaft shredder is composed of motor, hard tooth surface reducer, rotating cutter shaft, movable knife, frame, stand, box body, working platform and other main structures. Mount fixed knife frame, rotating knife shaft is equipped with removable inserts the knife. The knife number according to the size of the different models and rotating knife shaft and decide. Can removed after using a blunt knife again, save maintenance cost greatly, increase the service life of the machine.

Technical Parameters

|

Model

|

1900 |

1500 |

1200 |

1000 |

600 |

|

Main shaft power(kw)

|

4-90*2 |

4-45*2 |

4-37*2 |

4-30*2 |

4-15*2 |

|

Main shaft speed(r/min)

|

30-40 |

30-40 |

30-40 |

30-40 |

30-40 |

|

capacity(t/h)

|

10-25 |

8-18 |

6-15 |

5-10 |

2-5 |

|

weight(t)

|

15 |

12 |

6 |

5 |

2.5 |

|

Feeding Power(kw)

|

4-3kw |

4-3kw |

None |

None |

None |

|

Blade Qty

|

50 |

46 |

42 |

34 |

20 |

|

|

Different materials, the Qty of blade claws and blades are different, and can be customized. |

||||

|

Blade Dia.(mm)

|

Φ600 |

Φ550 |

Φ400 |

Φ400 |

Φ400 |

|

Output Size(cm)

|

3-10 |

3-10 |

3-10 |

3-10 |

3-10 |

|

Hopper Size(m)

|

2.3*2 |

2*2 |

1.4*1 |

1.2*1 |

0.82*0.9 |

|

Overall Dimension (L*W*H)(m)

|

8*2.5*2.4 |

4*1.7*2.4 |

3.2*2*1.9 |

3*2*1.9 |

2.6*2*1.9 |

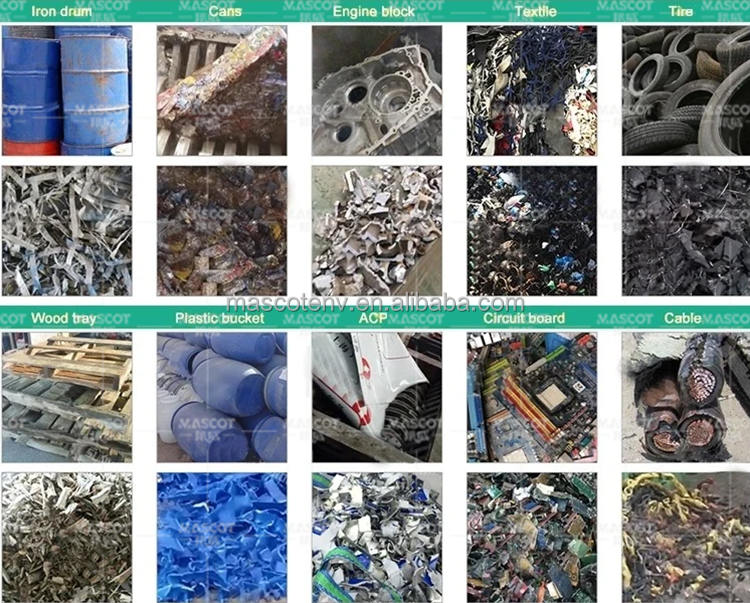

Application

1. Variety of hollow containers: Plastic beverage cans, plastic buckets, iron cans, packing boxes.

2. Waste household appliances: TV, washing machine, refrigerator shell

3. Pipe: Large pipes, tubes, PE pipes

4. Waste Template: wooden pallets, plastic pallets, truck pallet

5. Waste Tires: car tires, truck tires

6. Metal Scraps: car shell, Aluminum die casting scraps, engine shell, gearboxes, lead as well as the steel plate with less than 5mm thickness.

7. Food wastes, household garbage, animal carcasses, RDF derivatives, medical waste, biological straw, garden garbage

8. Rubber head materials, paper plant twisted rope.

Structure

The shredding machine is made of a shredding blade group, bearing box, frame, feeding systems, power systems, electrical control systems, etc.

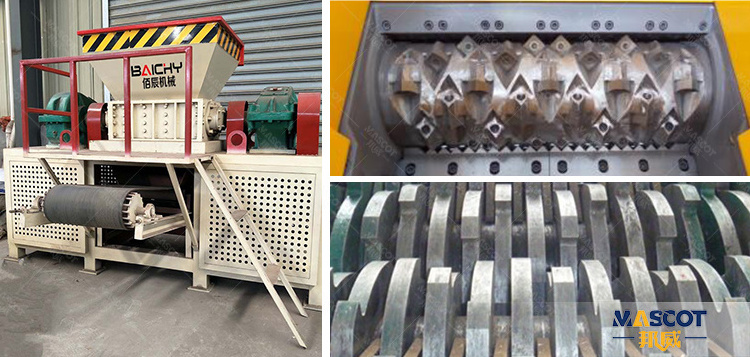

1. Main unit of shredding machine

The main parts adopt high-quality steel welding, to ensure stability in long heavy-duty working.

2. Bearing / Seal

The bearing seat adopts patent split open type, quickly removing the moving blade, fixed blade, bearing, etc. The maintenance and replacement of blades are very convenient.

3. Moving Blade / Fixed Blade

Blade material is Chromium silicon alloy. Fixed blade uses patented hook-type installation, to optimize the replacement function of the blade and make the maintenance, and replacement of the blade more efficient.

4. Blade Shaft

Blade shaft adopts high-strength heavy-duty special steel to process, a more reasonable fit for the blades to provide a strong impetus.Working Principle

Materials are fed to a shredding box with shredding blades by a feeding system, then after cutting, tearing, and extruding by blades to get a smaller size. Finally, the discharge of the product from the bottom.

Advantages

1. Double shaft shredding machine is suitable to process very big size of plastic material, such as plastic pipe, plastic board, wood, woven bags, tire, aluminum cans, the little diameter of copper wire, and pressing plastic film which the single Shaft plastic shredder can not process.

2. The machine with a big feeding mouth, can put the big plastic product freely.

3. The rotary blade and cutting blade and blade edge with special design, can get very high efficiency and high capacity

4. The machine is controlled by a PC system. The knife can be rotated in opposite direction and also can close automatically if something unexpected happens, with very high safety service

5. The knife material is made of alloy steel with high quality and a long lifetime.

6. Low speed, low noise, and little dust.

Zhengzhou Mascot Environmental Technology Co., Ltd is a company that integrates science, industry, and trade. The company mainly sells mechanical equipment and accessories, briquette-making machines, shredder machines, granulating machines, and mineral processing equipment. Our company follows a human-oriented mentality, honest, pioneering entrepreneurial spirit with scientific and technological innovation. We always regard technology as the motive force, and the market as the orientation to make the products at the first-class level. In product sales, we pursue the refined service and keep improving from pre-sales consulting, and on-purchase service to after-sales service.

Mascot's comprehensive service system covers technical support, after-sales service support, and spare part support, which is one of the important reasons why we are appreciated by customers. Mascot always strives to provide customers with the most valuable purchasing experience.

FAQ

1. Are you a manufacturing or trading company?

We are a factory, established in 2010.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at the lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already built many mining projects in China & Overseas.