- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

3800

-

MOQ:

-

1

-

Color:

-

Customized

-

Packing detail:

-

Standardexportationpacking

-

Usage:

-

Powder Coating Workpieces

-

After-sales Service Provided:

-

Online support

-

Keywords:

-

Powder Coating Room

-

Equipment Name:

-

Automatic Reciprocating Spraying Machine

-

Coating Technology:

-

Latest Automatic Coating

-

Used for:

-

Powder Coated Parts Curing

-

Control System:

-

Manual Control

Quick Details

-

Machine Type:

-

Machine, Spray Booths, Painting Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Sandblasting Machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BZB

-

Voltage:

-

380V/220V

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

3800

-

MOQ:

-

1

-

Color:

-

Customized

-

Packing detail:

-

Standardexportationpacking

-

Usage:

-

Powder Coating Workpieces

-

After-sales Service Provided:

-

Online support

-

Keywords:

-

Powder Coating Room

-

Equipment Name:

-

Automatic Reciprocating Spraying Machine

-

Coating Technology:

-

Latest Automatic Coating

-

Used for:

-

Powder Coated Parts Curing

-

Control System:

-

Manual Control

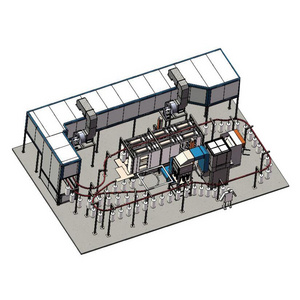

Power and Free Overhead Conveyor Powder Coating Line Automatic Powder Paint Equipments

Powder coating equipment includes powder coating booth, powder curing oven, conveyor systems and

surface cleaning equipment by using powder electrostatic adherence principle to the surface of product.

In contrast of liquid paint coatings, powder coating has thicker coatings and the most important is the powder

could be recycled.

We have two types of powder coating line:

- Thermo curing

- Thermo plastic

Thermo curing is most often electrostatically applied by spraying in a booth provided with a recovery system

with cyclone or with filter only. Often the booth system used is a fast colour change system. After application

the powder is cured in an oven either infrared or convection or a combination, at approximately 80-220 oC.

Thermo plastic powders (like e.g. nylon) are wide applied by dipping (sintering) in a fluidized powder hopper.

The products are then preheated to 200-300 oC and dipped into the powder.This process is used when the

products have a need for a thicker layer or when the products have a complex interior geometry.

Baozhongbao presents three type of powder recycling system:

- Small cyclone combined with filter recycling system.

- Bag type filter element recycling system

- Big cyclone combined with filter recycling system.