- Product Details

- {{item.text}}

Quick Details

-

Body material:

-

Stainless Steel 316

-

Valve type:

-

Disco check valve

-

Size:

-

DN15-DN100

-

Medium:

-

Fresh Water, sea water, food stuff, all kinds of oil

-

Working Temperature:

-

-100-400

-

MOQ:

-

1 Piece

-

OEM:

-

Avaliable

-

Working pressure:

-

PN40

Quick Details

-

Place of Origin:

-

Shandong, China

-

Standard or Nonstandard:

-

Standard

-

Product name:

-

PN40 Stainless Steel DN200 Non Return Lift Wafer Check Valve

-

Body material:

-

Stainless Steel 316

-

Valve type:

-

Disco check valve

-

Size:

-

DN15-DN100

-

Medium:

-

Fresh Water, sea water, food stuff, all kinds of oil

-

Working Temperature:

-

-100-400

-

MOQ:

-

1 Piece

-

OEM:

-

Avaliable

-

Working pressure:

-

PN40

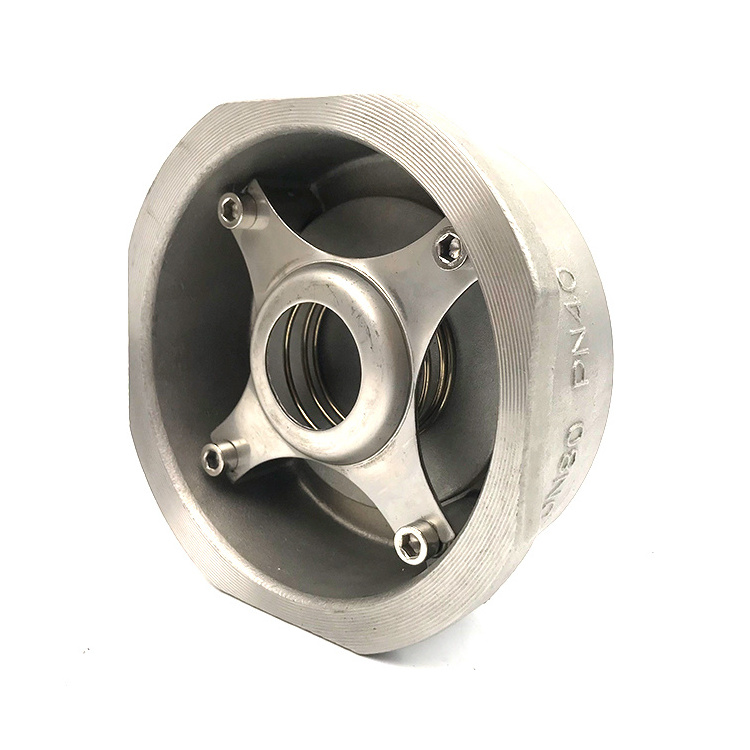

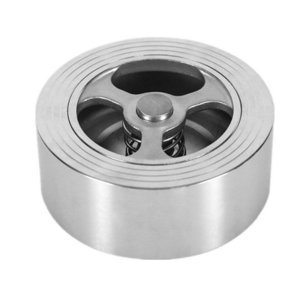

PN40 Stainless Steel DN200 Non Return Lift Wafer Check Valve

Disc check valves

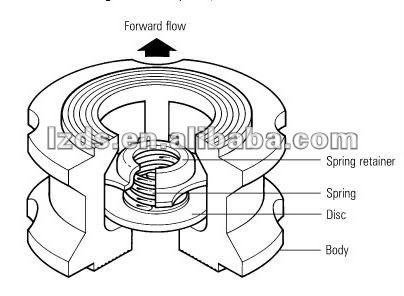

The disc check valve consists of four main components: the body, a disc, a spring and a spring retainer. The disc moves in a plane at right angles to the flow of the fluid, resisted by the spring that is held in place by the retainer. The body is designed to act as an integral centring collar that facilitates installation. Where a 'zero leakage' seal is required, a soft seat can be included.

A disck check valve

When the force exerted on the disc by the upstream pressure is greater than the force exerted by the spring, the weight of the disc and any downstream pressure, the disc is forced to lift off its seat, allowing flow through the valve. When the differential pressure across the valve is reduced, the spring forces the disc back onto its seat, closing the valve just before reverse flow occurs. This is shown in Figure 12.3.4. The presence of the spring enables the disc check vale to be installed in any direction.

Operation of a disc check valve

The differential pressure required to open the check valve is mainly determined by the type of spring used. In addition to the standard spring, there are several spring options available:

- No spring - Used where the differential pressure across the valve is small.

- Nimonic spring - Used in high temperature applications.

- Heavy-duty spring - This increases the required opening pressure. When installed in the boiler feedwater line, it can be used to prevent steam boilers from flooding when they are unpressurised.

Laizhou Dongsheng Valve Corporation located in Laizhou Yantai city Shandong Province, is a manufacturer of high quality valves primarily for export products are mainly OEM products since 2002.

We have 180 employees including 18 technicians, covering an area of 10200 square meters, also having advanced craftsmanship and technology. We mainly produce various check valves (for example,single disc swing check valve,double disc swing check valve,ball check valve,lift check valve, butterfly valves,diaphragm valves ,ball valves and so on). Our products are widely used in municipal water and wastewater ,oil,chemical, food and other fields.

Our entire valves are designed and manufactured according to ANSI (ASME), DIN, BS, JIS and other standard. Also, we ensure the best quality for customers, and our strict quality assurances systems are conducted throughout the entire production at the standard of ISO9001:2008 and CE.

We try to enlarge our oversea markets and we have received a good reputation from our customers in the USA, West Europe, the UK, Southeast Asia,Spain and Russian .Besides, we always make delivery on time and will provide you with best quality and reasonable prices.

All in all , our aim is to be your most reliable supplier.

Factory Show:

Our Team:

Exhibitions:

Q1: How long is the delivery time?

A1: Generally it's 5-10 days we have stock. Or it's 15-90 days depend on different product and quantity.

Q2: What about the payment term?

A2: T/T 30% deposit, balance payment after finished production before shipment. Or as discussed.

Q3: Can I have a sample order?

A3: Yes, Laizhou Dongsheng Valve agree sample order, mixed different models is also acceptable.

Q4: What's your MOQ?

A4: Laizhou Dongsheng Valve can support 1 pc order. Welcome you to check our quality.

Q5: What's your quality inspection? Do you test all your goods before delivery?

A5: Yes, 100% test. It integrates R&D, casting, production, processing, painting, assembly, testing, sales and after-sales service, and strict quality requirements, according to GB, ASME, API, DIN standard, and Laizhou Dongsheng Valve have gained ISO9001;2008, CE, and TUV certification.

Q6: Could I customize special request valve or new design products?

A6: Laizhou Dongsheng Valve have own R&D team and more than 70 researchers and engineers. Can give you the best support on quality management and techniques, meet your different needs.

Q7: How does your factory do regarding quality control?

A7: Laizhou Dongsheng Valve Quality is priority. Valve always attach great importance to quality controlling from the very beginning to the very end. Laizhou Dongsheng Valve has gained ISO9001;2008, CE, TUV, authentication.