- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

5.5-15kw

-

Dimension(L*W*H):

-

6200*2600*1800mm

-

Weight:

-

3800 kg

-

Product Name:

-

Toilet Tissue Paper Roll Rewinding Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Reeling Speed:

-

150-200m/min

-

Perforation Pitch:

-

4 perforating blade 90-160mm; 2 perforating blade 180-320mm

-

Parameter Setting:

-

PLC screen operation system

-

Unwinding Unit:

-

1-3 layers15-30gsm

-

Embossing Bottom Roller:

-

Felt roller, wool roller and rubber roller (depend on selection)

-

Unwinding Unit Driving:

-

Gear box driving

-

Edge Embossing Unit:

-

Steel to steel

-

Raw material:

-

Waste paper or wood pulp or bamboo,rice straw or sugarcane bagasse

Quick Details

-

Production Capacity:

-

contact us

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YDF

-

Voltage:

-

220V/380V

-

Power:

-

5.5-15kw

-

Dimension(L*W*H):

-

6200*2600*1800mm

-

Weight:

-

3800 kg

-

Product Name:

-

Toilet Tissue Paper Roll Rewinding Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Reeling Speed:

-

150-200m/min

-

Perforation Pitch:

-

4 perforating blade 90-160mm; 2 perforating blade 180-320mm

-

Parameter Setting:

-

PLC screen operation system

-

Unwinding Unit:

-

1-3 layers15-30gsm

-

Embossing Bottom Roller:

-

Felt roller, wool roller and rubber roller (depend on selection)

-

Unwinding Unit Driving:

-

Gear box driving

-

Edge Embossing Unit:

-

Steel to steel

-

Raw material:

-

Waste paper or wood pulp or bamboo,rice straw or sugarcane bagasse

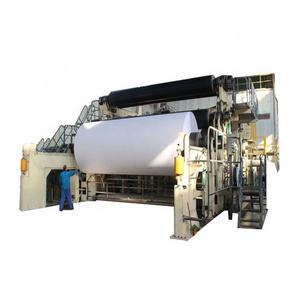

5~6 tons per day Toilet Tissue Jumbo Roll Production Line

From waste paper,wood,bamboo,rice straw etc.

Product Overview

5~6 tons per day Tissue Production Line

This production line is mainly consisted of paper pulping system and Jumbo tissue roll making machine.

1.The pulping system is a process in which raw materials, such as waste books, paper, edge bleaching straw pulp board, bleaching wood pulp board, etc., are processed into fibrous water suspension which meets the requirements of paper making, and then sent to the paper machine by the flow system to meet the requirements of users.

2.Paper machine is to meet the paper making requirements of the pulp water suspension by the filter dehydration forming, mechanical extrusion dehydration and drying process then making into paper. The use of raw materials are: waste paper, old newspaper and white waste paper edges and so on. It can produce toilet paper, facial tissue paper, napkin paper, drawing paper and so on. The machine with reliable quality, stable performance, easy operation, energy saving and environmental protection, paper making machine is the ideal product in machinery field.

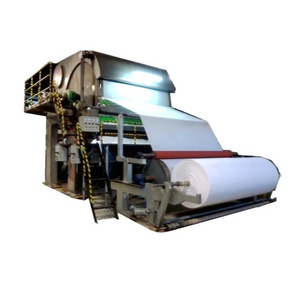

FEATURES AT A GLANCE

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

|

1. Main Product:

|

Toilet paper, napkin paper and drawing and so on

|

|

2. Grammage:

|

15~30g/㎡

|

|

3. Equipment form

|

The inversion of slurry

|

|

4. Capacity:

|

5~6T/24h

|

|

5. Raw paper width:

|

1880-2000mm

|

|

6. Design speed:

|

180m/min

|

|

7. Transmission speed:

|

70-150m/min

|

|

8. Dynamic balancing speed:

|

300m/min

|

|

9. Roller balance:

|

G2.5 class

|

|

10. Dryer balance:

|

C4 class

|

|

11. Winding paper roll:

|

C1.6 class

|

|

12. Transmission mode:

|

Ac motor frequency control of motor speed digital distribution transmission

|

|

13. Arrangement mode:

|

Right or left arrangement(selected by the user)

|

|

14. Gauge:

|

2400mm

|

|

15.Large equipment 1

|

Dryer cylinder:Ø2500mm×1 set

|

|

16.Large equipment 2

|

Cylinder mould:Ø1500 mm×1set

|

PRODUCT CONFIGURATION

ABOUT OUR COMPANY

OUR MARKET

FAQ

SEND INQUIRY

Hot Searches