- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

10000 ml

-

Place of Origin:

-

henan

-

Weight (KG):

-

2000 KG

-

Product name:

-

Blow Molding Machine

-

Bottle material:

-

Pet Plastic

-

Key words:

-

Bottle Blow Making Machine

-

Machine type:

-

Stretch Bottle Blowing

-

Use:

-

Blow Bottle

-

Function:

-

Auto Blow Molding Machine

-

Suitable bottle:

-

Drink Bottle

-

Power:

-

28KW

-

Voltage:

-

380V/50HZ

-

Hollow part volume:

-

10-25L

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Neck Diameter(mm):

-

140 mm

-

Max.Bottle Diameter(mm):

-

220 mm

-

Max.Bottle Height(mm):

-

370 mm

-

Bottle Volume(ml):

-

10000 ml

-

Place of Origin:

-

henan

-

Weight (KG):

-

2000 KG

-

Product name:

-

Blow Molding Machine

-

Bottle material:

-

Pet Plastic

-

Key words:

-

Bottle Blow Making Machine

-

Machine type:

-

Stretch Bottle Blowing

-

Use:

-

Blow Bottle

-

Function:

-

Auto Blow Molding Machine

-

Suitable bottle:

-

Drink Bottle

-

Power:

-

28KW

-

Voltage:

-

380V/50HZ

-

Hollow part volume:

-

10-25L

-

Marketing Type:

-

Hot Product 2021

Product Features

Blow Molding Machine

Blow molding machine is a kind of equipment that makes plastic pellets into hollow containers through blow molding process. At

present, the more common models include hollow extrusion blowing machines that use PP and PE for one molding, and PET, PC or PP

for two moldings. The injection stretch blow molding machine, as well as the newly developed multi-layer hollow extrusion blow

molding and stretch blow molding.At present, most of the blow molding machines are still two-step blow molding machines, that is,

the plastic raw materials must be made into preforms and then blown. Nowadays, environmentally friendly plastics made of PET are

commonly used. Blow molding machine: After the liquid plastic is sprayed out, the wind blowing from the machine is used to blow

the plastic body to a certain shape of the mold cavity to make a product. This kind of machine is called a blow molding machine.

It is also a type of blow molding machine, that is, a hydraulic blow molding machine.

The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in a split mold while it

is hot (or heated to a softened state), and compressed air is introduced into the parison immediately after closing the mold to

blow the plastic parison. It expands and sticks closely to the inner wall of the mold, and after cooling and demoulding, various

hollow products are obtained.

Blow molding machine is a kind of equipment that makes plastic pellets into hollow containers through blow molding process. At

present, the more common models include hollow extrusion blowing machines that use PP and PE for one molding, and PET, PC or PP

for two moldings. The injection stretch blow molding machine, as well as the newly developed multi-layer hollow extrusion blow

molding and stretch blow molding.At present, most of the blow molding machines are still two-step blow molding machines, that is,

the plastic raw materials must be made into preforms and then blown. Nowadays, environmentally friendly plastics made of PET are

commonly used. Blow molding machine: After the liquid plastic is sprayed out, the wind blowing from the machine is used to blow

the plastic body to a certain shape of the mold cavity to make a product. This kind of machine is called a blow molding machine.

It is also a type of blow molding machine, that is, a hydraulic blow molding machine.

The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in a split mold while it

is hot (or heated to a softened state), and compressed air is introduced into the parison immediately after closing the mold to

blow the plastic parison. It expands and sticks closely to the inner wall of the mold, and after cooling and demoulding, various

hollow products are obtained.

Product application

Stretch Blow Molding Machine

Plastic hollow containers are widely used in beverages, pharmaceuticals, cosmetics, food and chemical industries due to their

light weight, low cost and high safety. More manufacturers choose plastic containers instead of glass containers.

Plastic hollow containers are widely used in beverages, pharmaceuticals, cosmetics, food and chemical industries due to their

light weight, low cost and high safety. More manufacturers choose plastic containers instead of glass containers.

Plastic Blow Moulding Machine

1) Deflashing unit for the neck/bottom and scrap and finished product conveyor, lessening manual processes involved and then improving working efficiency

1) Deflashing unit for the neck/bottom and scrap and finished product conveyor, lessening manual processes involved and then improving working efficiency

2) Adopting neck polishing machine and leak testing device to enhance bottle quality and work efficiency

3) Robot arms and conveyor for finished bottles are adopted to work well with auxiliary machines

4) Purely hydraulic system, with the design of optimized hydraulic oil loop, guarantees good performance, high speed and stable running

5) Strong clamping force, in joint-type clamping design, makes sure of good quality of the product inside the moulds

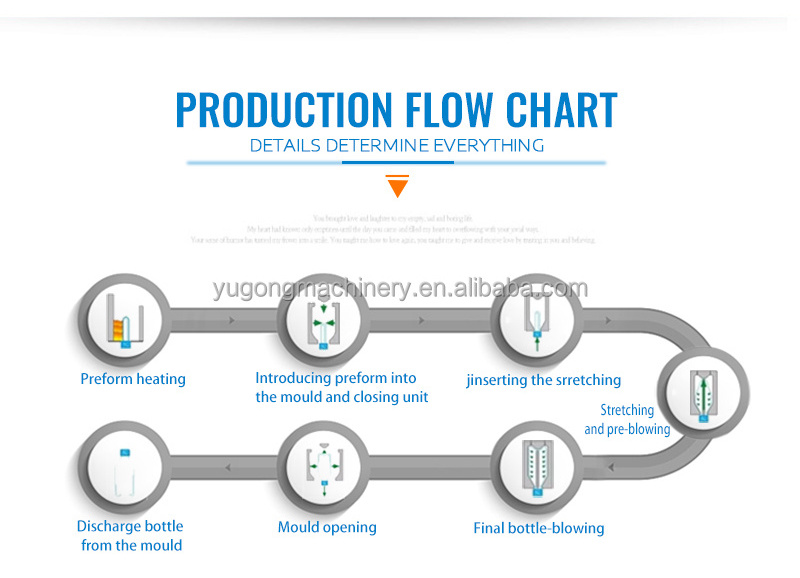

Production Process

Pet Bottle Blowing Machine

1. Preheating The preform (preform) is irradiated by an infrared high-temperature lamp, and the body part of the preform (preform) is heated and softened. In order to maintain the shape of the bottle mouth, the preform (preform) mouth does not need to be heated, so a certain amount of heat is required. cooling device to cool it.

1. Preheating The preform (preform) is irradiated by an infrared high-temperature lamp, and the body part of the preform (preform) is heated and softened. In order to maintain the shape of the bottle mouth, the preform (preform) mouth does not need to be heated, so a certain amount of heat is required. cooling device to cool it.

2. Blow molding In this stage, the preheated preforms (preforms) are placed in the blow molds that have already been prepared, and high-pressure inflation is carried out in them to blow and draw the preforms (preforms) into the desired bottles. Blow molding machines on the market are generally divided into two types: automatic and semi-automatic. The fully automatic bottle blowing machine completes the two operations of blowing the bottle

together through the operation of the manipulator, eliminating the process of manually placing the preheated preform (preform) into the blow mold in the middle. Greatly accelerated the rate of production, of course, the price is higher than the

semi-automatic.

.

Specification

|

item

|

value

|

|

Plastic Processed

|

PET, PVC, PE, PE/PP

|

|

Max.Bottle Height(mm)

|

370mm

|

|

Neck Diameter(mm)

|

140mm

|

|

Max.Bottle Diameter(mm)

|

220mm

|

|

Bottle Volume(ml)

|

10000ml

|

|

Condition

|

New

|

|

Application

|

Bottle

|

|

Blow Moulding Type

|

Stretch Blow Moulding

|

|

Place of Origin

|

henan

|

|

Weight (KG)

|

2000KG

|

|

Automation

|

Semi-automatic

|

|

Warranty

|

2 years

|

|

Key Selling Points

|

High Productivity

|

|

Showroom Location

|

Pakistan, Philippines

|

|

Applicable Industries

|

Advertising Company

|

|

Marketing Type

|

Hot Product 2021

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

2 years

|

|

Core Components

|

Bearing, Motor

|

|

Product name

|

Blow Molding Machine

|

|

Bottle material

|

Pet Plastic

|

|

Key words

|

Bottle Blow Making Machine

|

|

Machine type

|

Stretch Bottle Blowing

|

|

Use

|

Blow Bottle

|

|

Function

|

Auto Blow Molding Machine

|

|

Suitable bottle

|

Drink Bottle

|

|

Power

|

28KW

|

|

Voltage

|

380V/50HZ

|

|

Hollow part volume

|

10-25L

|

Product Description

Packing & Delivery

Hot Searches