- Product Details

- {{item.text}}

Quick Details

-

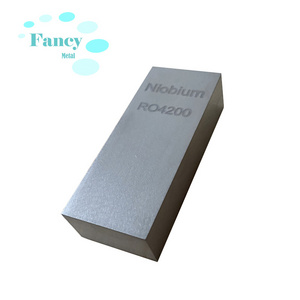

Model Number:

-

MH-TB422

-

Shape:

-

sheet/Block/bar

-

Material:

-

Niobium Tantalum Alloy, Niobium Tantalum Alloy

-

Chemical Composition:

-

Niobium Tantalum

-

Color:

-

Natural

-

Process:

-

Forging + Rolling + Grinding + Polishing

-

MOQ:

-

100kg

-

Surface Treatment:

-

grinding and polishing

-

Key words:

-

Niobium Tantalum Alloy

-

Finish:

-

Polishing

-

Standard:

-

ISO10270-1995

-

Certificate:

-

ISO 9001:2008

-

Advantage:

-

high ductility and density

Quick Details

-

Application:

-

Electronics industry

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

MH

-

Model Number:

-

MH-TB422

-

Shape:

-

sheet/Block/bar

-

Material:

-

Niobium Tantalum Alloy, Niobium Tantalum Alloy

-

Chemical Composition:

-

Niobium Tantalum

-

Color:

-

Natural

-

Process:

-

Forging + Rolling + Grinding + Polishing

-

MOQ:

-

100kg

-

Surface Treatment:

-

grinding and polishing

-

Key words:

-

Niobium Tantalum Alloy

-

Finish:

-

Polishing

-

Standard:

-

ISO10270-1995

-

Certificate:

-

ISO 9001:2008

-

Advantage:

-

high ductility and density

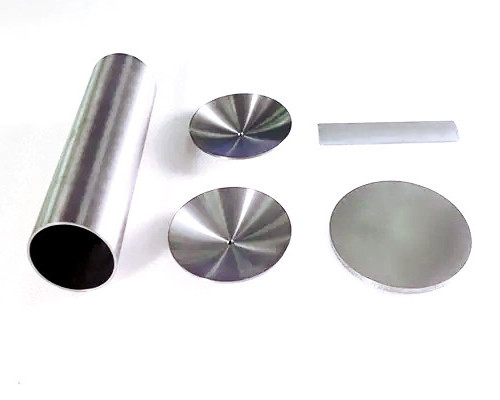

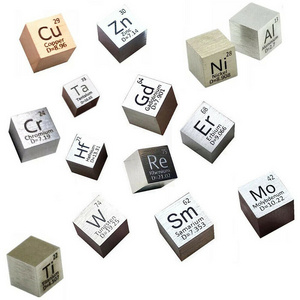

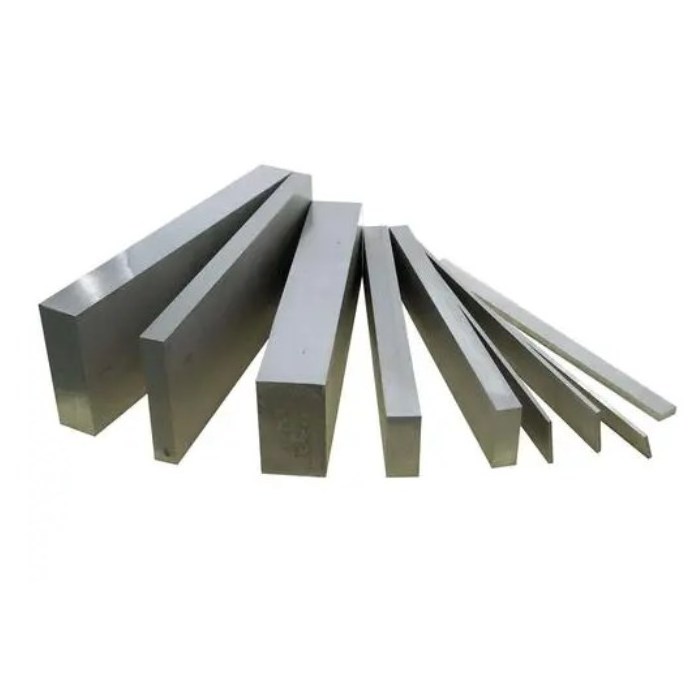

Products Description

|

Material:

|

Niobium Tantalum Alloy

|

|

Shape:

|

Bar

|

|

Color:

|

Natural metal color

|

|

Size:

|

Accept customized

|

|

Specification:

|

as agreement

|

|

Advantage:

|

Niobium Tantalum Alloy

Electronics industry, high ductility and density

|

|

MOQ

|

1KG

|

More details pictures for your reference.

Tantalum - based alloy with niobium and other elements. There are corrosion resistant type and capacitor type. The main brands of the former are KB141(37.5% Nb, 2.5% W, 2.0% Mo, residual tantalum), Ta-3Nb, etc. The latter mainly include Ta-25Nb, Ta-10Nb and so on. KB141 alloy has excellent ductility at low temperature, tensile strength up to 517GPa, and strong corrosion resistance, such as in 20% hydrochloric acid corrosion rate is only 2.5μm/a. Mainly used in the chemical industry. Ta-25Nb alloy leakage current is only 0.133μA/cm2, used as a thin film electrolytic capacitor. It is produced by powder metallurgy.

Hot selling recommend

Hot Searches