- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

1A2

-

Application:

-

gem polishing

-

Product name:

-

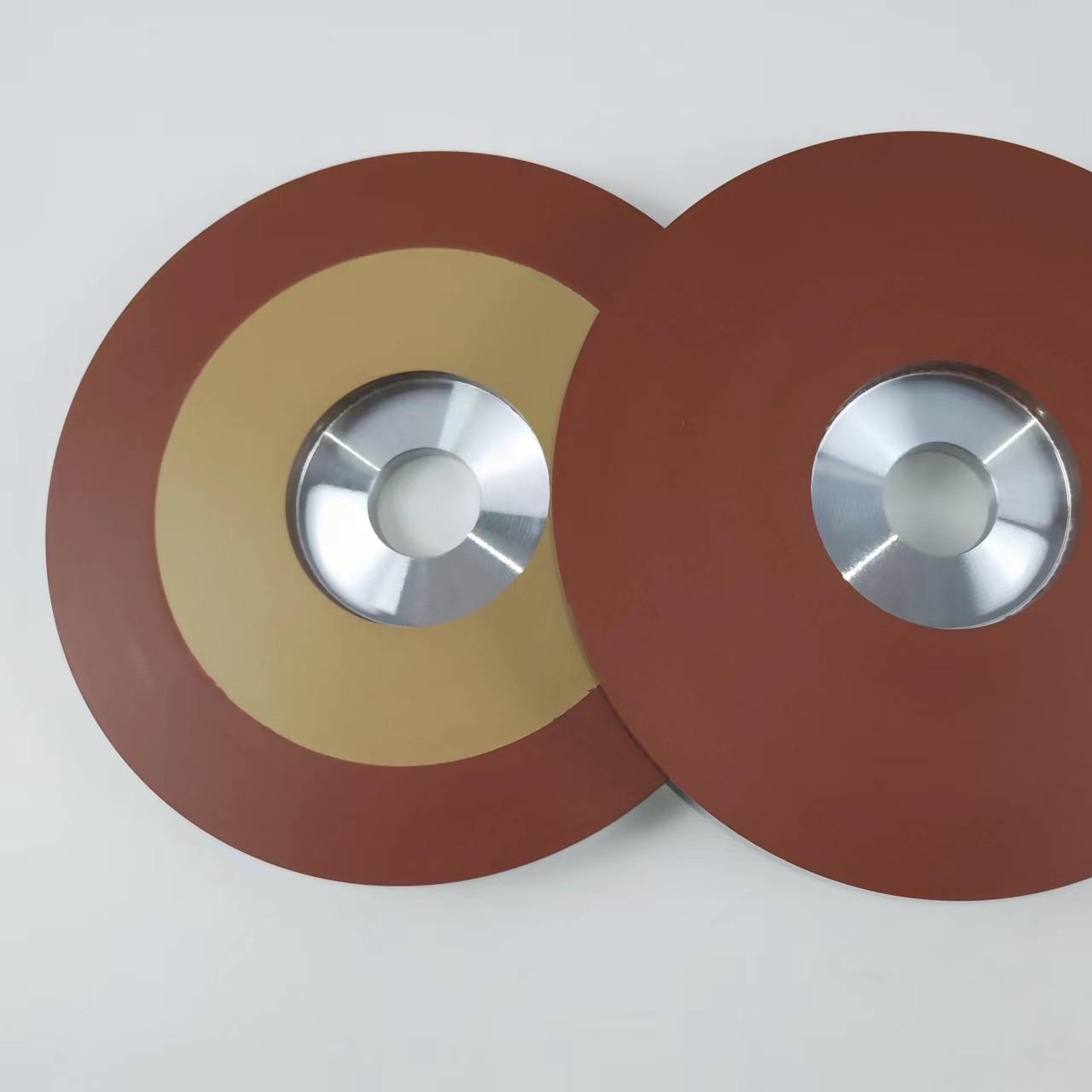

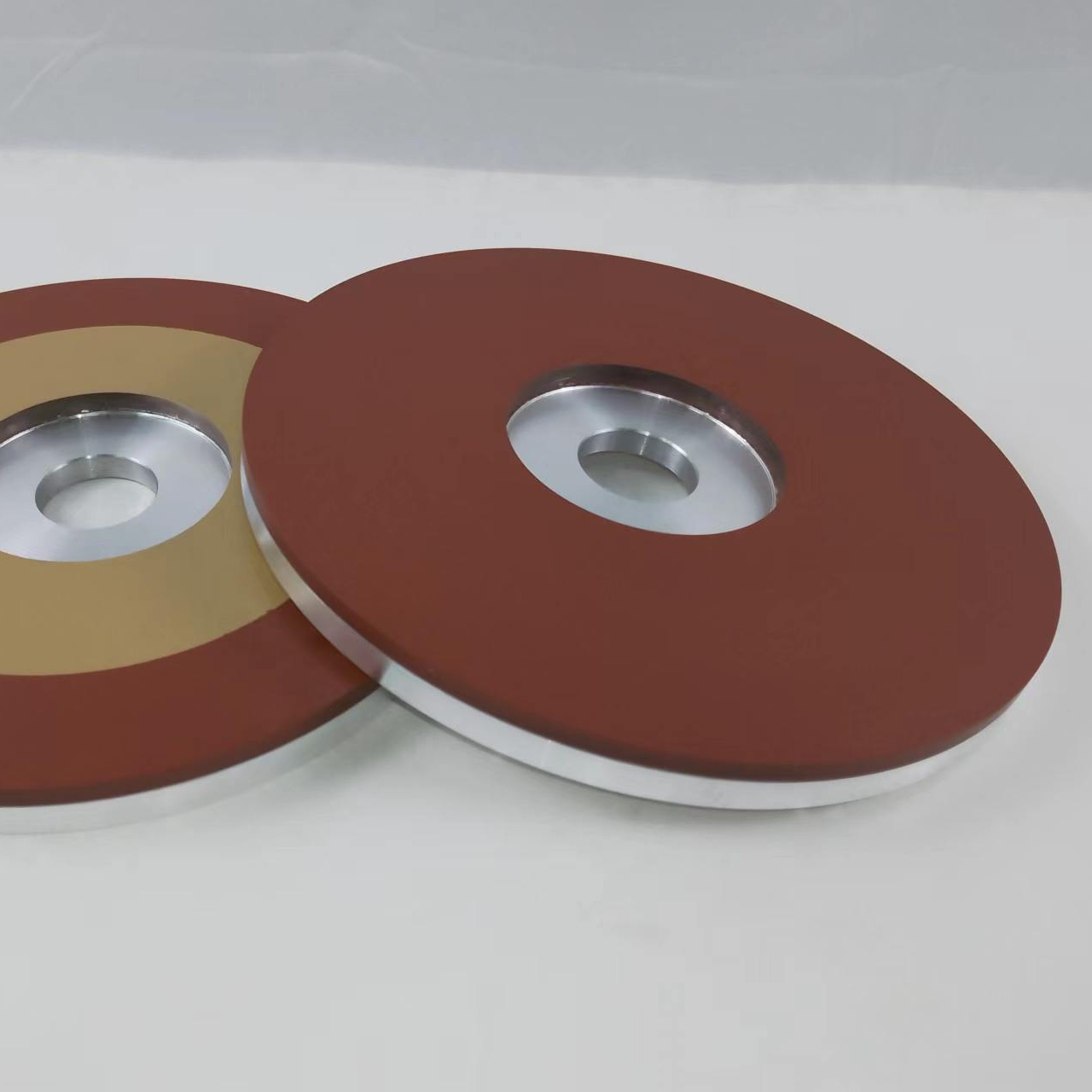

Grinding Disc

-

Material:

-

Aluminum Oxide

-

Usage:

-

Surface Polishing

-

Color:

-

Green

-

Shape:

-

Round Disc

-

Size:

-

200*70*3*12.7*20mm

-

Grit:

-

15000

-

Feature:

-

High Quallity

-

MOQ:

-

1PCS

Quick Details

-

Type:

-

Abrasive Disc

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Model Number:

-

1A2

-

Application:

-

gem polishing

-

Product name:

-

Grinding Disc

-

Material:

-

Aluminum Oxide

-

Usage:

-

Surface Polishing

-

Color:

-

Green

-

Shape:

-

Round Disc

-

Size:

-

200*70*3*12.7*20mm

-

Grit:

-

15000

-

Feature:

-

High Quallity

-

MOQ:

-

1PCS

Products Description

|

D(mm)

|

T(mm)

|

H(mm)

|

Grit

|

|||

|

150mm

|

38mm

|

25.4/19/15.8/12.7

|

#60, 140, 280, 600, 1200, 3000, 5000, 8000, 14000, 50,000

|

|||

|

200mm

|

50mm

|

25.4/19/15.8/12.7

|

#60, 140, 280, 600, 1200, 3000, 5000, 8000, 14000, 50,000

|

|||

|

Any nonstandard size and grits size can customised (tell us size or drawing is enought)

|

|

|

|

|||

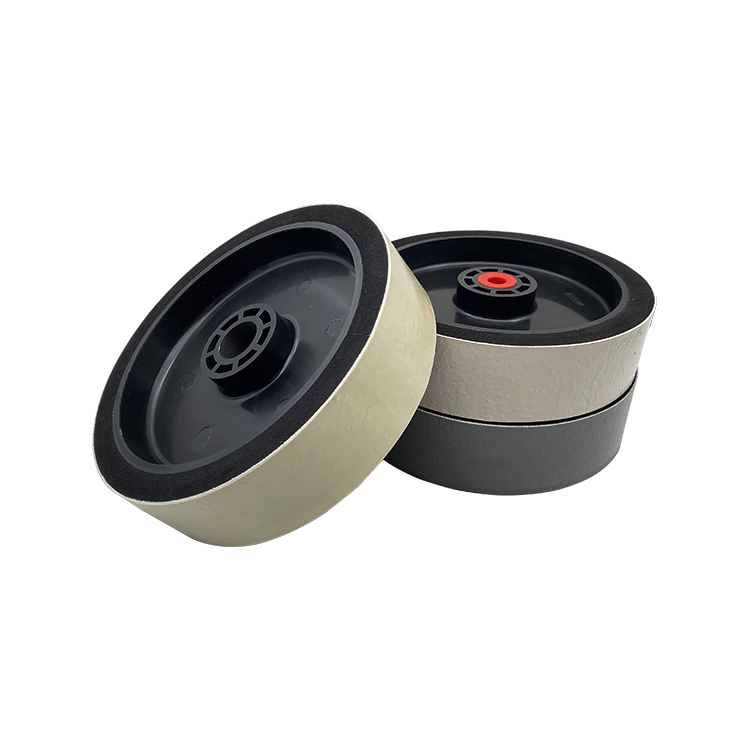

diamond CBN grinding sharpening wheels for gemstone

The flexible diamond grinding wheel is resin bond and Combined with selected diamond powder, To make the wheel have an extremely flexible and excellent cutting ability. Mainly used in the special-shaped processing of hard and brittle materials such as gemstone, crystal, glass, artificial crystal, ceramics, etc. Through the polishing from coarse to fine grain grinding wheels, the surface of make the work piece is extremely smooth and bright. At the same time, there are special grinding and polishing equipment, which is easy to operate simply and safety.

Product Features.

1. Diamond abraisve high density, high grinding efficiency

2. Sharp. Fast grinding and fast sharpneing your tools

3. Long life. Much longer life than traditional abrasive wheels

4. High viscosity,the sand not easy to drop

5. Well balanced each wheels

6. No dust coming out when sharpening and grinding

7. Customized design is available

3. Long life. Much longer life than traditional abrasive wheels

4. High viscosity,the sand not easy to drop

5. Well balanced each wheels

6. No dust coming out when sharpening and grinding

7. Customized design is available

Applications

1.It can be used for polishing precious stones such as gems and jade. It does not change the status of gemstone surface during grinding.

2.Can be used for surface polishing of zircon, various artificial crystals, glass crafts, etc.

3. It can be used for grinding the surface of small-scale handicrafts such as ceramic handicrafts, metal pendants, wood products, etc

4.Can be used for grinding and polishing glass lenses

5.Can be used for bracelet processing

6.Metal material processing

2.Can be used for surface polishing of zircon, various artificial crystals, glass crafts, etc.

3. It can be used for grinding the surface of small-scale handicrafts such as ceramic handicrafts, metal pendants, wood products, etc

4.Can be used for grinding and polishing glass lenses

5.Can be used for bracelet processing

6.Metal material processing

Selection of grinding wheel elements.

1.hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Relative products

Customer Reviews

Hot Searches